Electromagnetic shielding composite material based on graphene honeycomb structure, and preparation method and application thereof

A technology of electromagnetic shielding and honeycomb structure, applied in the direction of magnetic/electric field shielding, electrical components, etc., can solve the problems affecting the conductivity and electromagnetic shielding performance, and achieve the effects of improving conductivity and electromagnetic shielding performance, reducing weight, and uniform structure arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention also provides a preparation method of the electromagnetic shielding composite material described in the above technical solution, comprising the following steps:

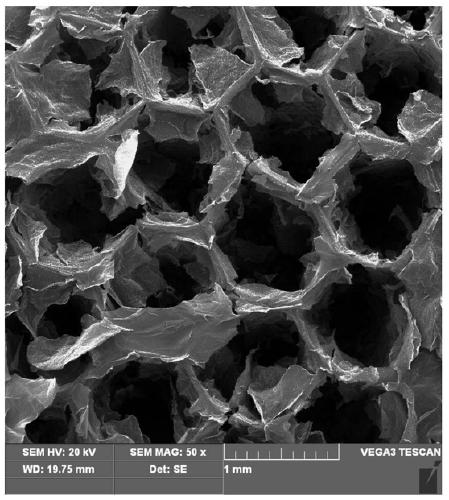

[0033] The aluminum oxide honeycomb board is immersed in the graphene oxide solution, and then freeze-dried to obtain a graphene oxide-aluminum honeycomb board composite structure;

[0034] Etching the aluminum oxide honeycomb plate in the graphene oxide-aluminum honeycomb plate composite structure with dilute hydrochloric acid, then drying to obtain the honeycomb structure graphene oxide;

[0035] Annealing the honeycomb structure graphene oxide in a hydrogen / argon mixed atmosphere to obtain honeycomb structure graphene;

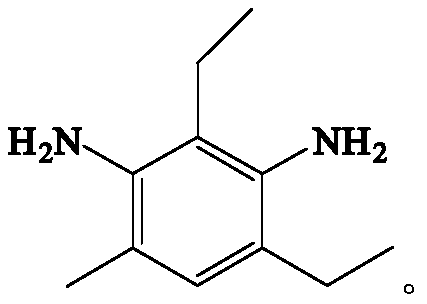

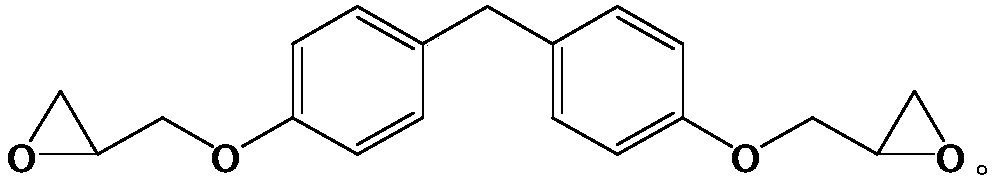

[0036] Mix epoxy resin and curing agent in a water bath, pour the resulting mixture into the honeycomb structure graphene, and then sequentially pump air and solidify to obtain the electromagnetic shielding composite material.

[0037] In the invention, the aluminum ...

Embodiment 1

[0060] Add 0.5 parts by weight of natural graphite flakes to 2 parts by weight of 98% concentrated sulfuric acid, stir at 80°C for 4 hours; add the product to 20 parts by weight of 98% concentrated sulfuric acid after dilution and suction filtration, and add 1.5 parts by weight KMnO 4 , stirred for 20min, heated to 35°C and stirred for 2h; added 30 parts by weight of deionized water and stirred for 15 minutes, then added 5 parts by weight of H 2 o 2 ; Then add 100 parts by weight of deionized water and 10 parts by weight of 12mol / L concentrated hydrochloric acid to leave standstill and centrifuge to obtain GO;

[0061] The aluminum oxide honeycomb board was immersed in the GO solution, and after ultrasonic treatment for 30 min, it was left to stand for 48 h to obtain the graphene oxide-aluminum honeycomb board composite structure. After it was placed in a freeze dryer for 48hrs, the aluminum oxide honeycomb board was etched with 10 parts by weight of 1.5mol / L dilute hydrochl...

Embodiment 2

[0066] Add 1 part by weight of natural graphite flakes to 4 parts by weight of 98% concentrated sulfuric acid, stir at 80°C for 6 hours; add the product to 40 parts by weight of 98% concentrated sulfuric acid after dilution and suction filtration, and add 3 parts by weight of KMnO 4 , stirred for 40min, heated to 35°C and stirred for 2h; added 60 parts by weight of deionized water and stirred for 15 minutes, then added 10 parts by weight of H 2 o 2 ; Then add 200 parts by weight of deionized water and 20 parts by weight of 12mol / L concentrated hydrochloric acid to leave standstill and centrifuge to obtain GO;

[0067] The aluminum oxide honeycomb board was immersed in the GO solution, and after ultrasonic treatment for 30 min, it was left to stand for 48 h to obtain the graphene oxide-aluminum honeycomb board composite structure. After it was placed in a freeze dryer for 72 hours, the aluminum oxide honeycomb board was etched with 10 parts by weight of 1.5 mol / L dilute hydro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Electromagnetic shielding performance | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com