Silicon carbide MOSFET high-temperature gate bias test method

A high-temperature gate bias and testing method technology, which is applied in the direction of single semiconductor device testing, etc., can solve problems such as SiC MOSFET thermal runaway, threshold voltage drift, etc., and achieve the effect of in-situ testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

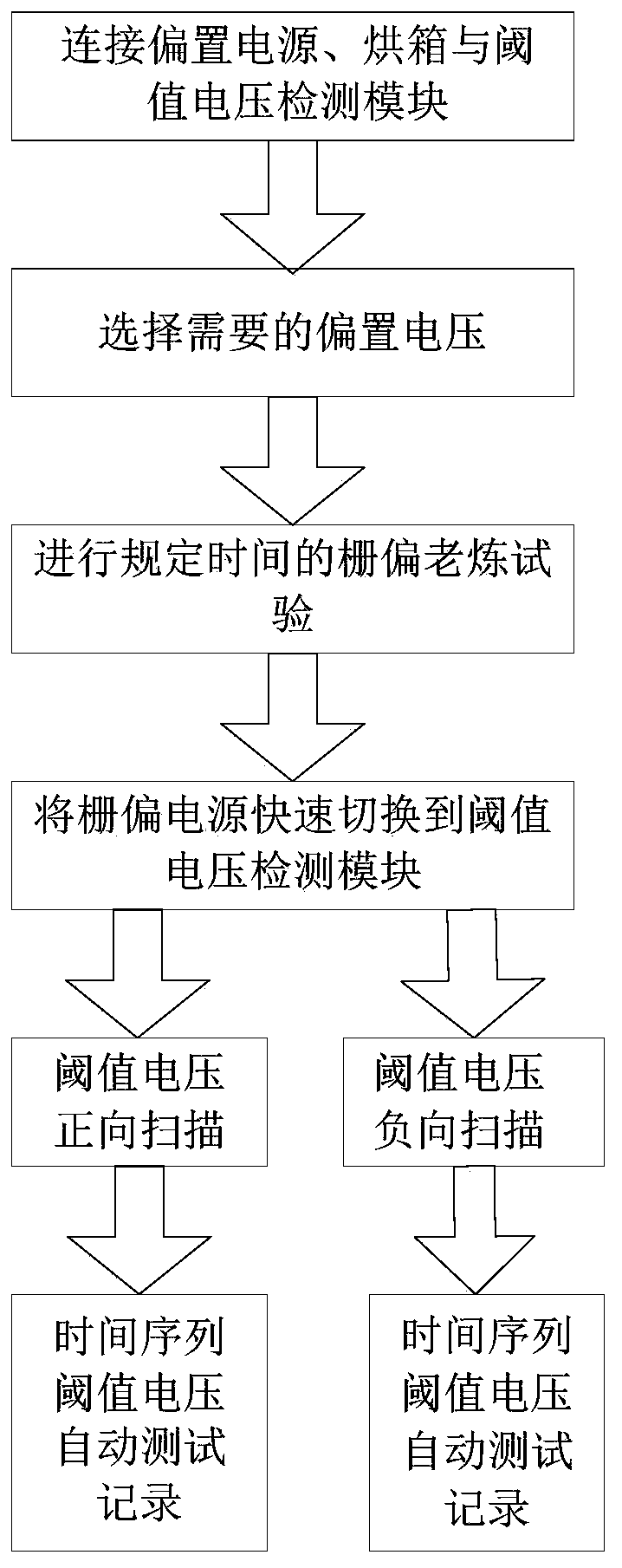

[0031] Such as figure 1 As shown, a silicon carbide MOSFET high temperature gate bias test method includes the following steps:

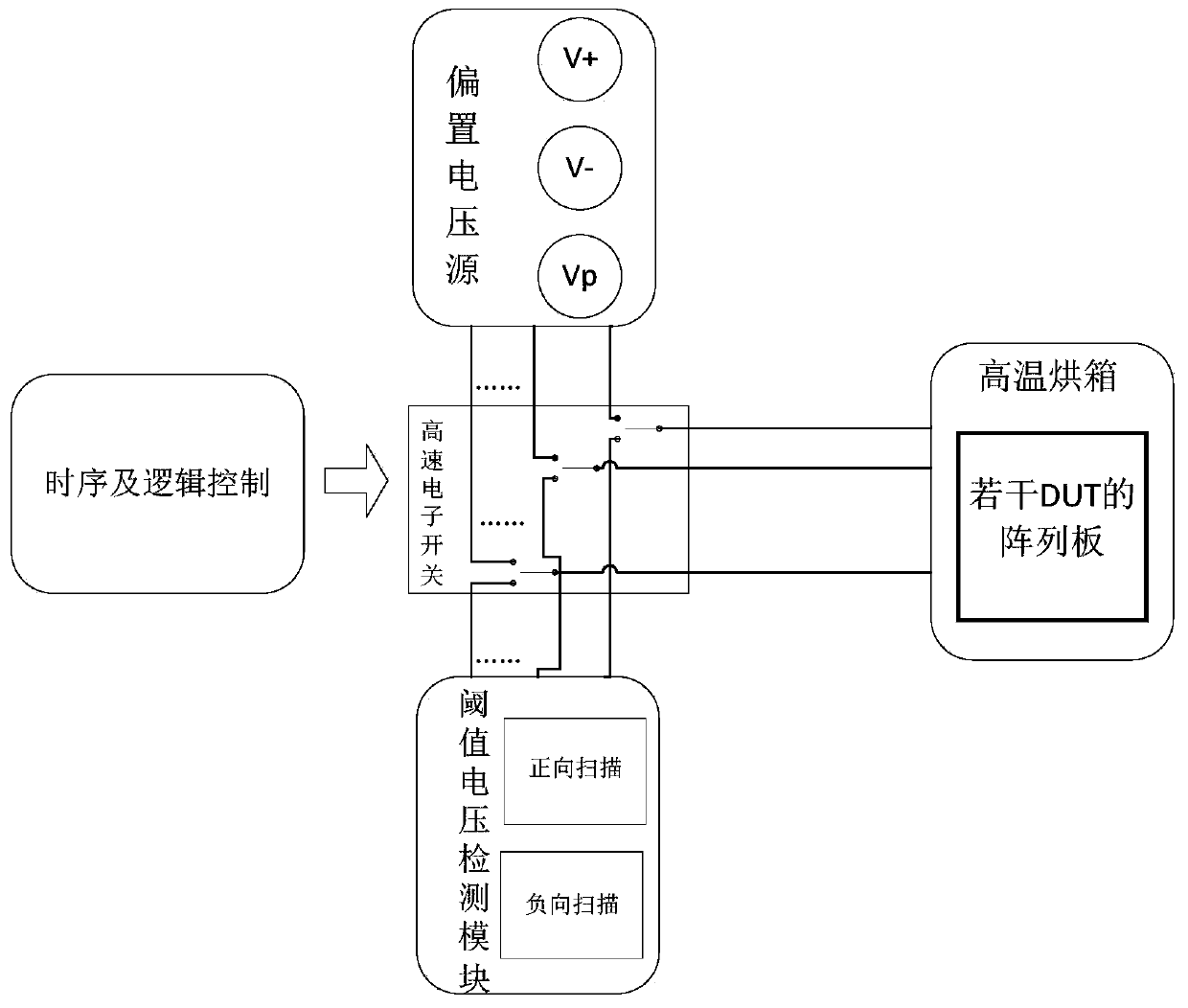

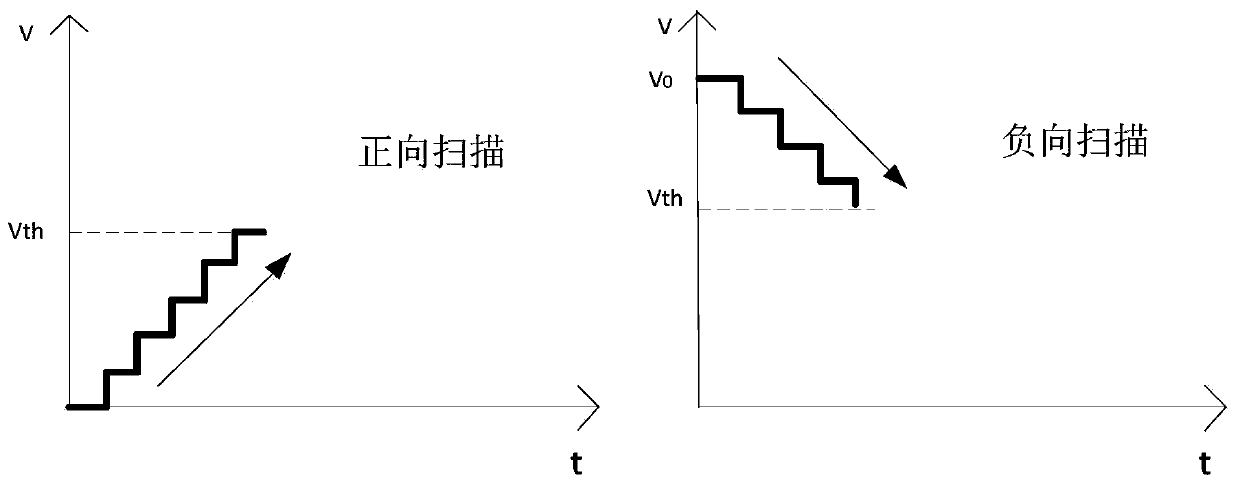

[0032] 1) Test system composition: the high temperature gate bias system is composed of four parts: voltage source, oven, threshold voltage detection, timing and logic control module. The voltage source is composed of positive voltage source, negative voltage source and pulse voltage source. The positive voltage source V ﹢It is used to detect the drift of the threshold voltage under the positive gate voltage, the negative voltage source V- is used to detect the drift of the threshold voltage under the negative gate voltage, and the pulse voltage source Vp is used to detect the lower threshold of the pulse gate voltage with a certain frequency voltage drift.

[0033] 2) Connection of the test system: put the array board of the device under test DUT into the oven, and the array board is respectively connected to the bias voltage source and the thresh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com