Method for preliminarily separating Fischer-Tropsch synthesized water by dividing-wall distillation column

A technology of dividing wall distillation and Fischer-Tropsch synthesis, which is applied in the field of preliminary separation of Fischer-Tropsch synthetic water by using a wall rectifying tower, can solve problems such as environmental protection and uneconomical, and achieve process energy consumption reduction, thermodynamic efficiency improvement, Effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

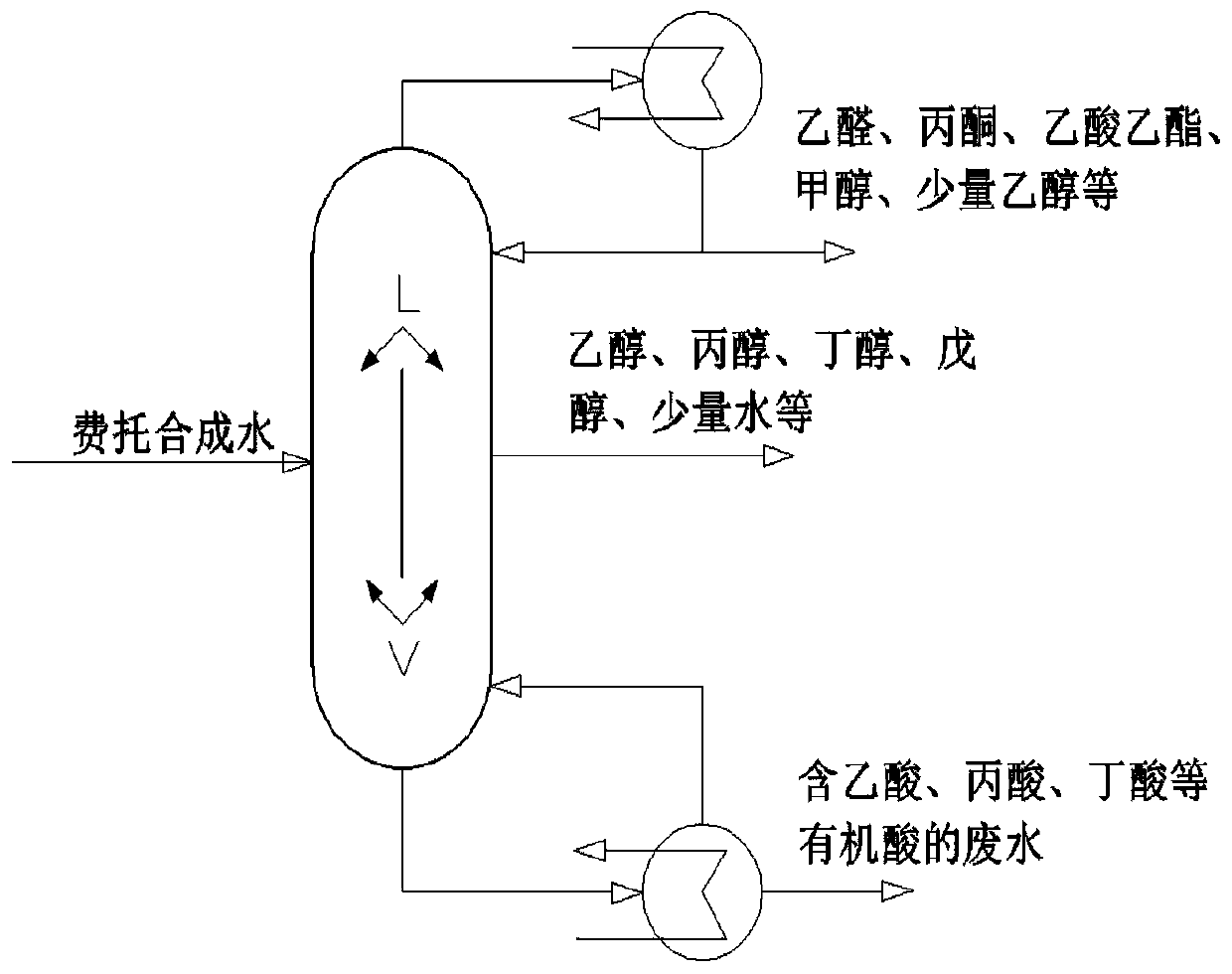

Embodiment 1

[0032] This embodiment is a method for preliminary separation of low-temperature Fischer-Tropsch synthetic water by using a rectifying tower with a dividing wall. The method includes using synthetic water produced by the low-temperature Fischer-Tropsch synthesis method as a raw material, and adopting a high-efficiency and energy-saving rectifying device for a rectifying wall of a dividing wall. Synthetic water raw materials are separated, and the top of the next-wall rectification tower is equipped with a condenser, and a reflux and recovery circuit, which can be used to extract the top product and adjust the reflux ratio; the second-wall rectification tower There is a reboiler at the bottom, which can provide heat for the evaporation of liquid in the whole rectification system; the middle part of the body of the rectifying column with dividing wall is provided with a vertical partition, and the two sides of the partition are divided into the pre-fractionation side and the main ...

Embodiment 2

[0049] This embodiment is a method for preliminary separation of high-temperature Fischer-Tropsch synthetic water by using a rectifying column next to the next wall. The process of this treatment method is the same as that of Example 1; the total number of theoretical plates is 60, and there are 25 theoretical plates on the upper side of the dividing plate. There are 9 theoretical plates on the lower side of the plate, and there are 26 theoretical plates in the entire partition height, the feed position is on the pre-fractionation side (counting from the bottom of the partition) on the sixth theoretical plate, and the side line extraction position is on the main tower side ( Counting down from the partition) the 15th theoretical board.

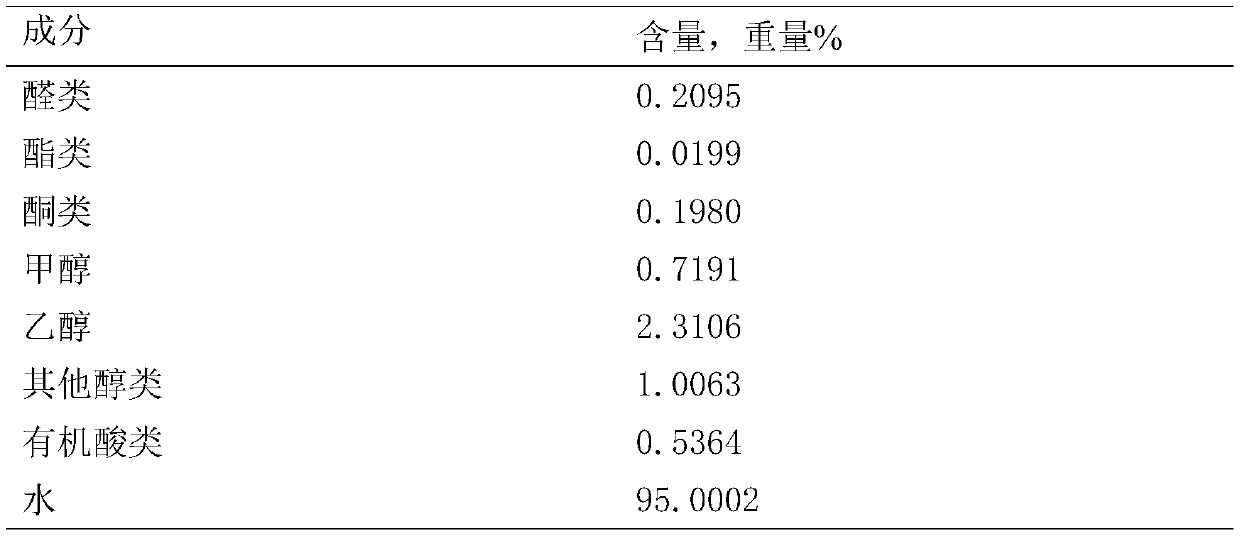

[0050] The composition of the high-temperature Fischer-Tropsch synthetic water raw material is as follows:

[0051] Raw material composition

[0052]

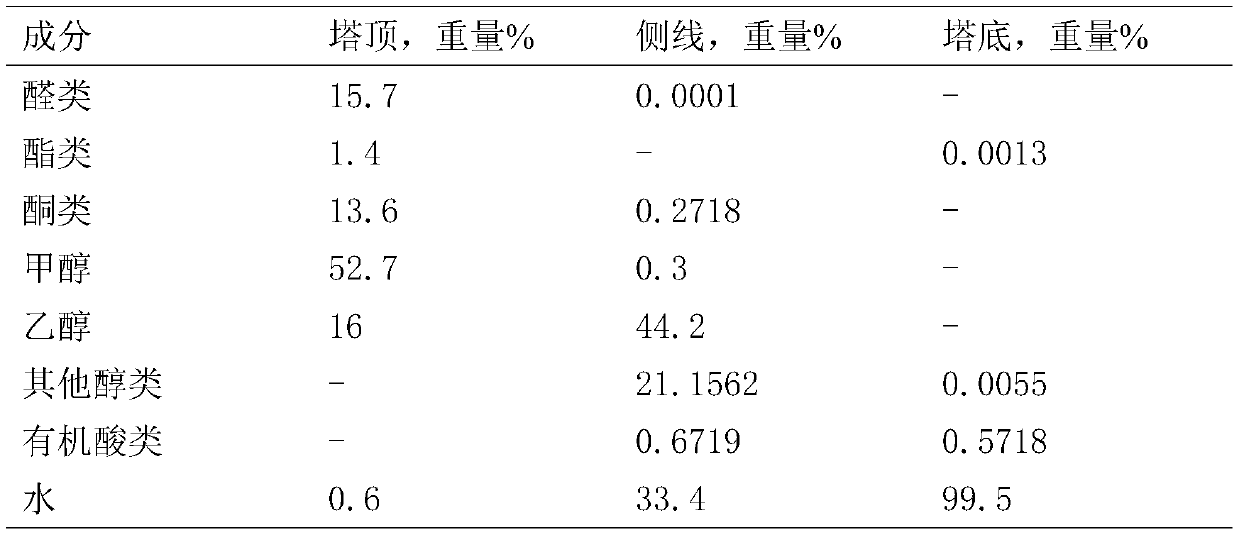

[0053]

[0054] (1) When the reflux ratio of the next-wall distillation column is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com