Preparation method of copper 2-ethylhexanoate

A technology of copper ethylhexanoate and copper carbonate is applied in the preparation of carboxylate, the preparation of carboxylate, the preparation of organic compounds, etc., and can solve the problems of complex processing technology, many synthesis steps, low cost of raw materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

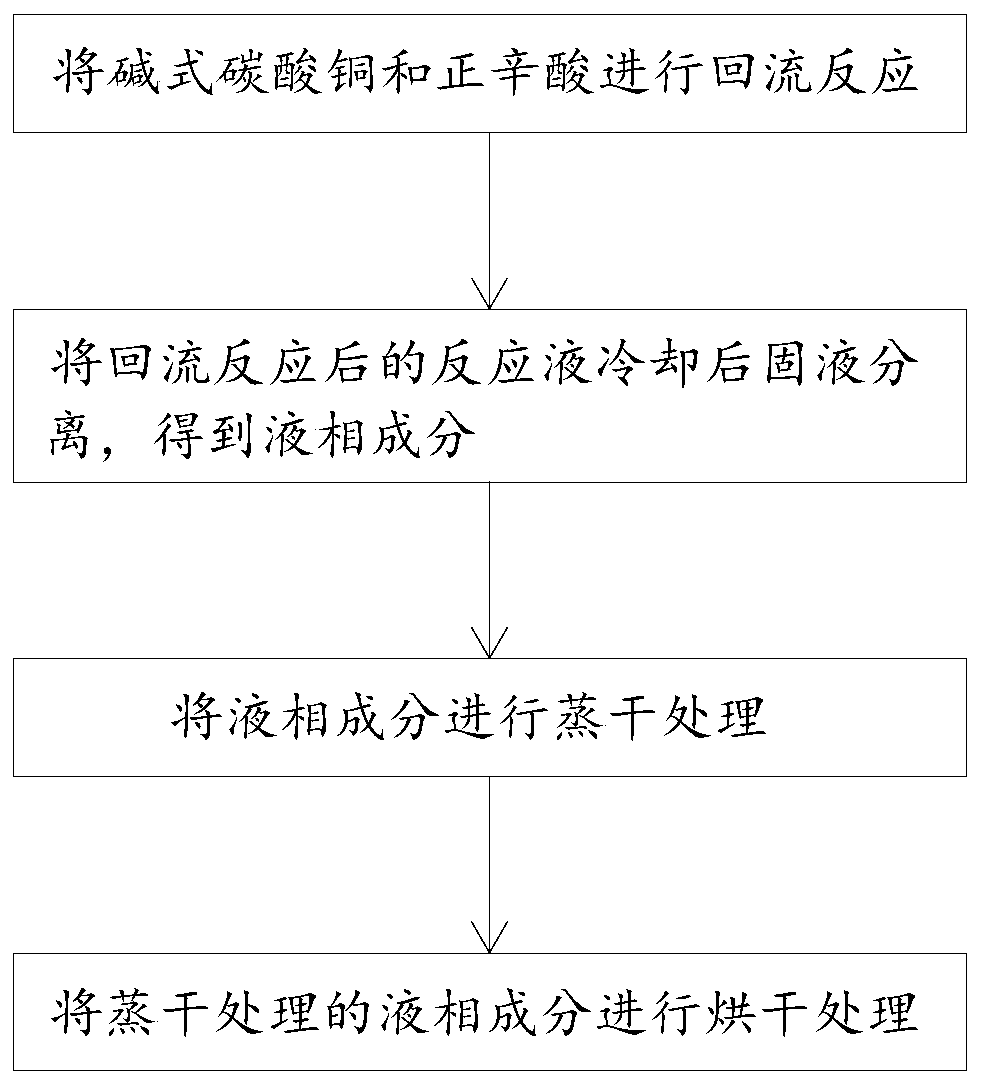

[0031] see figure 1 , the embodiment of the present application provides a kind of preparation method of copper 2-ethylhexanoate, comprising: carry out reflux reaction with basic copper carbonate and n-octanoic acid in polar organic solvent, the ratio of the molar ratio of basic copper carbonate and n-octanoic acid Not less than 1 / 4.

[0032] The copper 2-ethylhexanoate introduced in this application refers to copper n-2-ethylhexanoate unless otherwise specified.

[0033] The polar organic solvent used in this application refers to an organic substance that can fully dissolve n-octanoic acid and copper 2-ethylhexanoate generated by the reaction, while ensuring that it can be evaporated and refluxed at the reflux temperature. The type of the polar organic solvent is not specifically limited, it can be a single type of organic matter, such as: aromatic solvents, such as ethanol, benzene, toluene, xylene, etc.; or amides, such as formamide, acetamide . It can also be a mixture...

Embodiment 1

[0054] A preparation method of copper 2-ethylhexanoate, comprising:

[0055] S1. Weigh 50g of basic copper carbonate into a 1L round bottom flask, add 130g of n-octanoic acid, then add 500mL of absolute ethanol, stir to fully dissolve n-octanoic acid in absolute ethanol.

[0056] S2. Place the round-bottom flask in a water bath, install a condenser tube and feed condensed water, control the temperature of the water bath at 80° C., fully reflux for 36 hours, and the reaction solution gradually turns dark green.

[0057] S3. After the reflux reaction, the reaction solution is centrifuged, and the supernatant is taken after centrifugation to obtain the liquid phase components.

[0058] S4, controlling the temperature at 80° C. to evaporate the liquid phase components to dryness for 3 hours, and then controlling the temperature at 55° C. to dry the liquid phase components to obtain copper 2-ethylhexanoate.

Embodiment 2

[0060] A preparation method of copper 2-ethylhexanoate, comprising:

[0061] S1. Weigh 50g of basic copper carbonate into a 1L round bottom flask, add 105g of n-octanoic acid, then add 550mL of absolute ethanol, and stir to fully dissolve n-octanoic acid in absolute ethanol.

[0062] S2. Put the round-bottomed flask in a water bath, install a condenser tube and feed in condensed water, control the temperature of the water bath at 70°C, fully reflux for 39 hours, and the reaction solution gradually turns dark green.

[0063] S3. After the reflux reaction, the reaction solution is centrifuged, and the supernatant is taken after centrifugation to obtain the liquid phase components.

[0064] S4, controlling the temperature at 70° C. to evaporate the liquid phase components to dryness for 4 hours, and then controlling the temperature at 55° C. to dry the liquid phase components to obtain copper 2-ethylhexanoate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com