Diurea-based organic small molecular gel factor, preparation method thereof, thixotropic hydrocarbon fuel gel material and preparation method thereof

A small molecule gel and gel material technology, applied in the field of supramolecular chemistry, can solve the problems of difficult purification and many synthesis steps, and achieve the effects of wide application prospects, simple synthesis steps, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

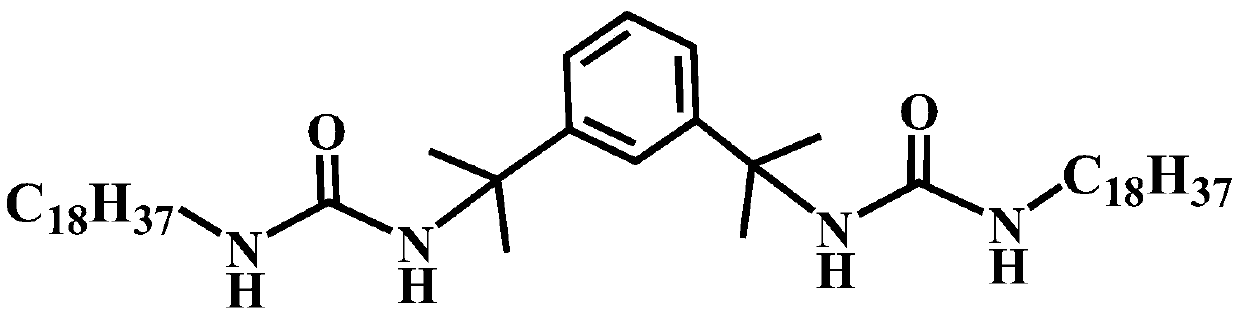

[0031] The preparation method of the diureido organic small molecule gelling factor of the present invention comprises the following steps:

[0032] Dissolve octadecylamine in the reaction solvent, then add tetramethylxylylene diisocyanate, react under nitrogen protection for 4 to 12 hours, and the reaction temperature is 20°C to 40°C. After the reaction is stopped, the reaction solution is removed by filtration and dried to obtain White solid powder product; add 4-10L of reaction solvent per mole of octadecylamine, and the molar ratio of octadecylamine to m-tetramethylxylylene diisocyanate is 2:1-3:1.

[0033] The molar ratio of the aforementioned octadecylamine to m-tetramethylxylylene diisocyanate is preferably 2.2:1 to 2.6:1.

[0034] The above reaction solvent is one or more of toluene, benzene, tetrahydrofuran, dichloromethane, chloroform, ethyl acetate or 1,2 dichloroethane.

[0035] The above-mentioned reaction solvent is preferably added in an amount of 4-8 L of reac...

Embodiment 1

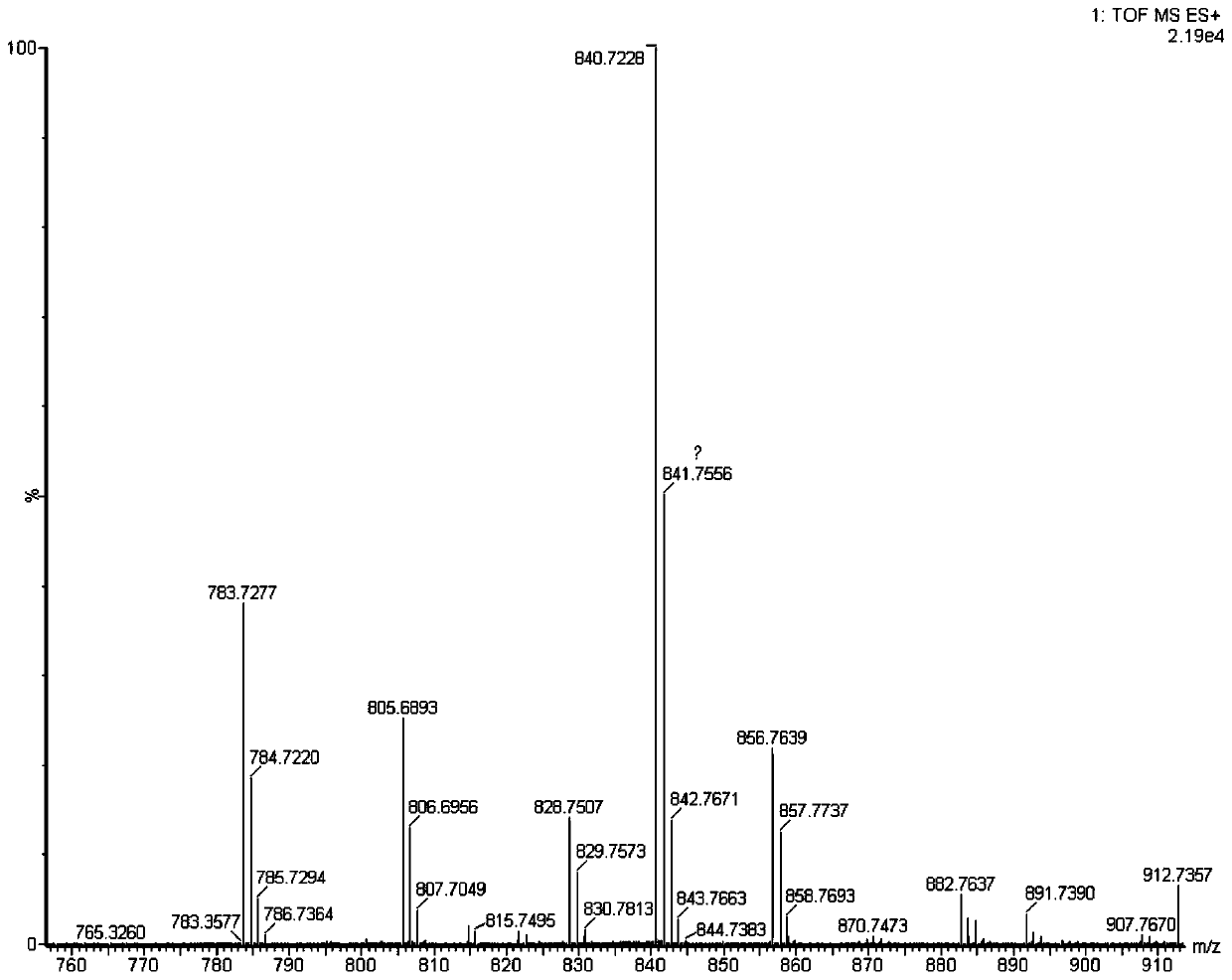

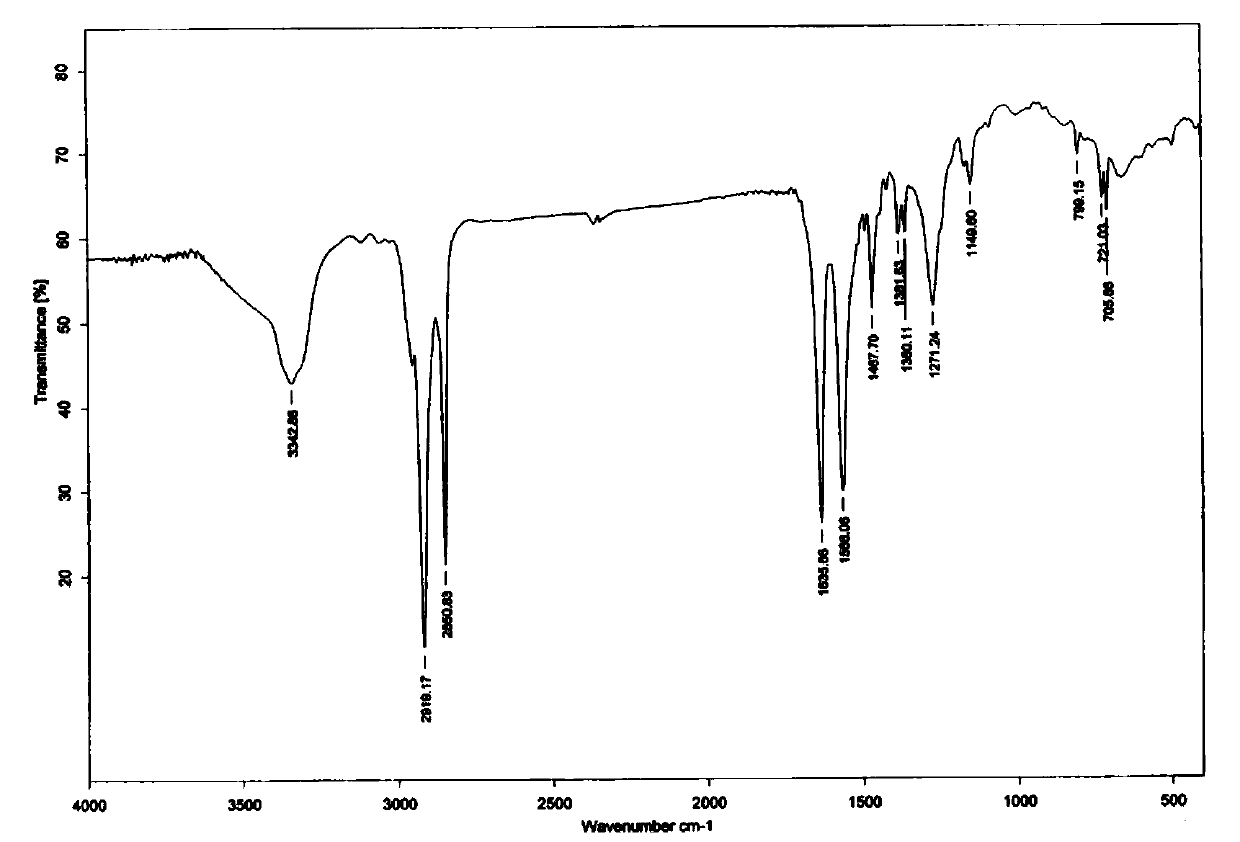

[0045] In a 2.5-liter three-necked flask, add 54.5 grams of n-octadecylamine, 400 milliliters of ethyl acetate, and drop in 24.4 grams of meta-tetramethylxylylene diisocyanate, and the reaction solution is reacted under nitrogen protection at a reaction temperature of 20° C. After 12 hours, after the reaction was completed, it was filtered and dried to obtain 74.4 grams of a white solid powder product.

Embodiment 2

[0047] In a 2.5-liter three-necked flask, add 59.2 grams of n-octadecylamine, 600 milliliters of toluene, drop in 24.4 grams of m-tetramethylxylylene diisocyanate, and react the reaction solution for 8 hours at a reaction temperature of 35° C. under stirring under nitrogen protection. , filtered after the reaction, and dried to obtain 75.2 grams of a white solid powder product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com