Composite modified asphalt bridge deck waterproof bonding layer

A technology of composite modified asphalt and waterproof bonding layer, which is applied in the direction of asphalt material adhesives, bridges, adhesives, etc., can solve the problems of premature aging, insufficient crack resistance, and reduced flexibility of asphalt materials, and achieve excellent bonding. Performance and water resistance, effect of improved temperature and mechanical properties, high water resistance and resistance to deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1 Preparation of Epoxy Modified Asphalt

[0034] 1. Prepare materials: 100 parts of base asphalt, 15 parts of epoxy resin, 8 parts of curing agent, 4 parts of vulcanizing agent, 1.5 parts of curing accelerator, 3 parts of styrene-butadiene rubber, 0.5 part of 500 mesh talcum powder;

[0035] Preparation steps:

[0036] In the first step, put the melted base asphalt into the mixer, heat it at 170-180°C, add styrene-butadiene rubber, and continue stirring through the colloid mill for 15-30 minutes, so that the styrene-butadiene rubber is evenly distributed in the base asphalt;

[0037] In the second step, the temperature is controlled at 130-150 ℃, adding epoxy resin, vulcanizing agent, curing accelerator and talcum powder, and continuing to stir for 15-20 minutes to mix evenly;

[0038] The third step is to keep the temperature at 120-140 ℃, add the curing agent into the mixer, and stir for 10-15 minutes to obtain epoxy-modified asphalt.

Embodiment 2

[0039] Example 2 Preparation of thermoplastic elastomer modified asphalt

[0040] 1. Preparation of materials: 100 parts of matrix asphalt, 25 parts of epoxidized natural rubber, 35 parts of thermoplastic elastomer, 1.0 part of polyphenylene ether with a fineness of 20-40 mesh, and 4 parts of glass fiber with a length ≤ 5mm;

[0041] 2. Steps:

[0042] The first step is to put the melted matrix asphalt into a high-speed shear mixing emulsifier, the temperature is controlled at 150-160°C, first add thermoplastic elastomer, and shear at a high speed of 4000rpm for 30 minutes to obtain an asphalt binder;

[0043] In the second step, heat the asphalt binder prepared in the first step to 170-180°C, then add polyphenylene ether and epoxy natural rubber, and shear at a high speed of 4000rpm for 40 minutes until the epoxy natural rubber is completely integrated into the asphalt adhesive Finally, add glass fiber and stir for 5 minutes to obtain thermoplastic elastomer modified asphalt...

Embodiment 3

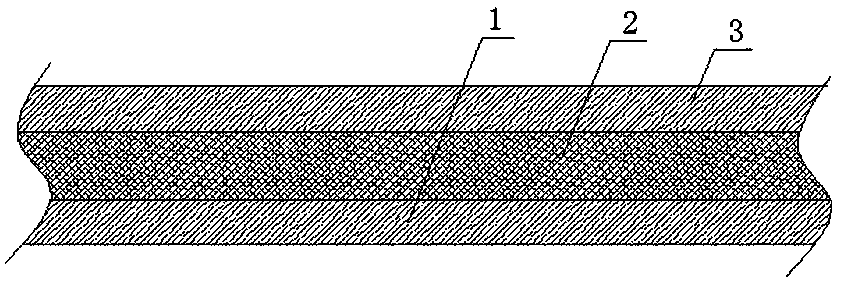

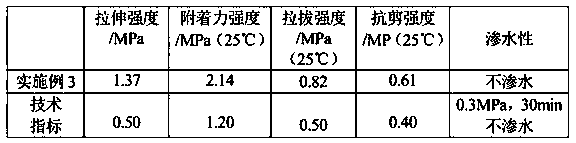

[0044] Example 3 Laying a composite modified asphalt bridge deck waterproof bonding layer

[0045] Its specific construction method is:

[0046] The first step is to apply epoxy modified asphalt at a rate of 0.4kg / m within 2 hours after the completion of the construction on the concrete bridge deck. 2 Spray directly, and lay the epoxy modified asphalt lower bonding layer 1. During the temporary storage and spraying of the asphalt, it needs to be in a state of constant stirring at 120-140°C;

[0047] In the second step, press 0.6kg / m on the adhesive layer 1 under the epoxy modified asphalt 2 Lay the thermoplastic elastomer modified asphalt waterproof layer 2 with the same amount as the first step;

[0048] The third step is laying the engineering plastic modified asphalt upper bonding layer 3 on the thermoplastic elastomer modified asphalt waterproof layer 2, and the laying method is the same as the first step.

[0049] The waterproof adhesive layer of the composite modified...

PUM

| Property | Measurement | Unit |

|---|---|---|

| deformation temperature | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com