Transmissive blue laser lighting component

A laser lighting and transmissive technology, applied to components of lighting devices, optical elements for changing the spectral characteristics of emitted light, lighting devices, etc., can solve heat conduction and laser spot uniformity, reduce light efficiency of laser lighting devices, Problems such as the heat dissipation and thermal conductivity of fluorescent substances are reduced, and the thermal conductivity and laser spot scattering performance are excellent, and the manufacturing process is less difficult.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

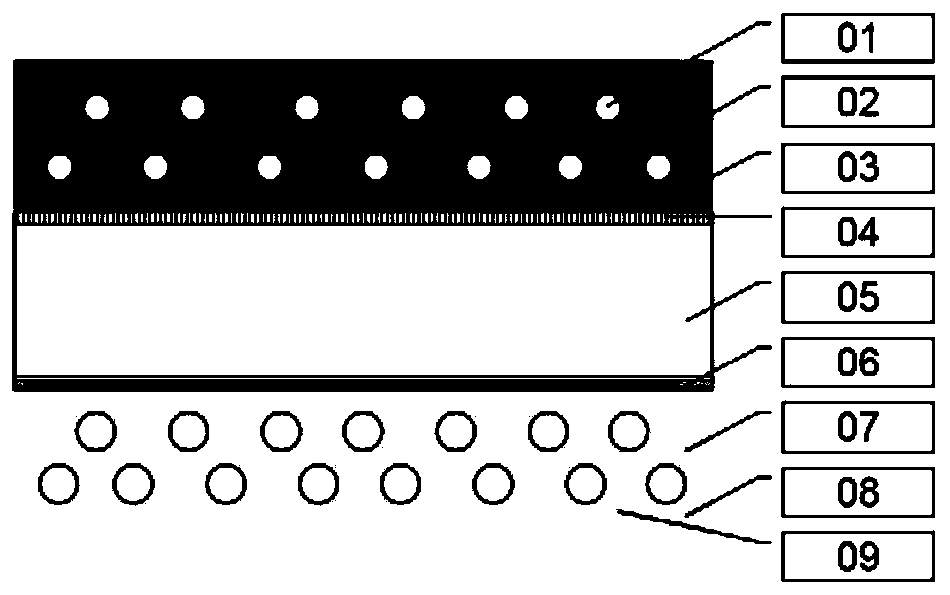

[0068] Will Y 3 Al 5 o 12 : Ce fluorescent powder and low-melting point glass powder are mixed evenly according to the mass ratio of 1:1, and an appropriate amount of terpineol is added during mixing to adjust the viscosity of the slurry. Then the above slurry was painted onto a sapphire substrate coated with a reflective film that enhances yellow light reflection, the thickness of the painting was 100 μm, and the thickness of the substrate was 1 mm. Mix hollow alumina (outer diameter 2 μm, hollow diameter 0.4 μm) and low-melting point glass powder according to the mass ratio of 1:99, and add an appropriate amount of terpineol to adjust the viscosity of the slurry. Then the above slurry was painted onto a sapphire substrate coated with an anti-reflection film to enhance blue light transmission, and the thickness of the painting was 100 μm. Then, the substrate carrying the two kinds of slurry is sintered at high temperature, the sintering temperature is 650° C., and the sint...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com