Image sensing unit and manufacturing method thereof, and image sensor

A sensor unit and image technology, applied in radiation control devices and other directions, can solve the problems of excessively thick device layer processing difficulty, reduced incident photon absorption efficiency, and large incident light angle, so as to overcome low light absorption efficiency and improve light Absorption efficiency, the effect of prolonging the effective optical path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

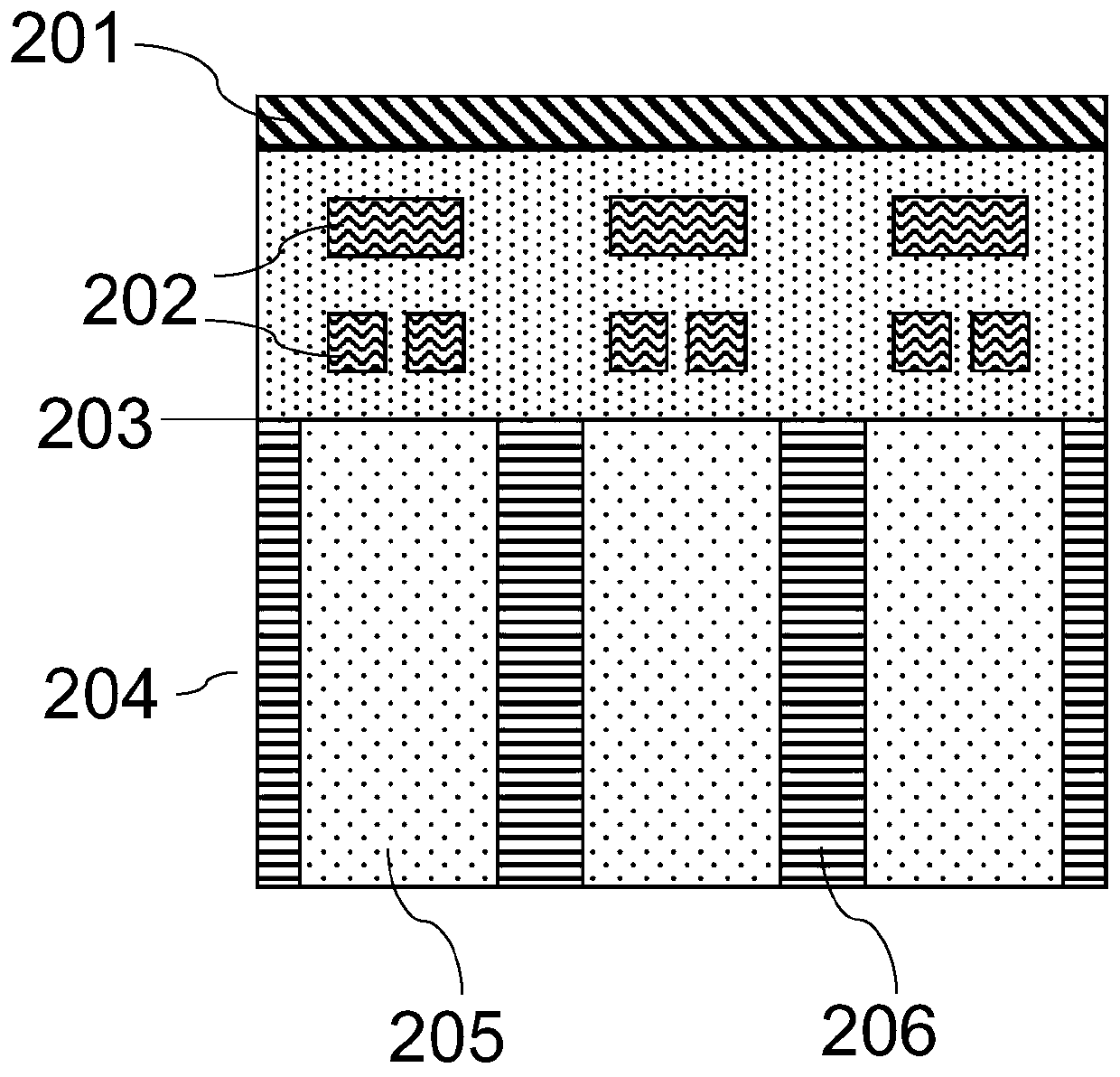

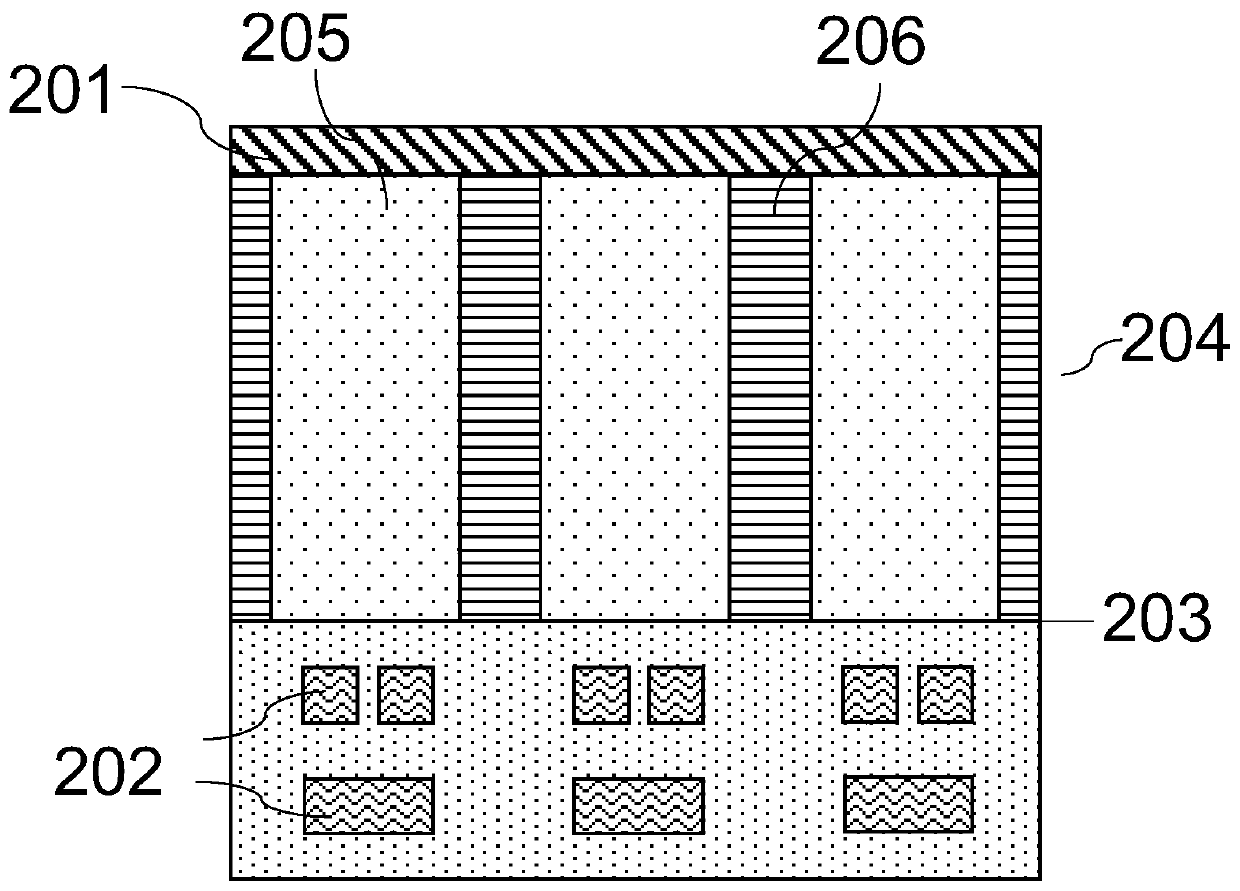

[0055] An image sensing unit. The image sensing unit is sequentially provided with a substrate, a circuit layer, a silicon oxide layer and a silicon detection layer from bottom to top. The silicon detection layer is surrounded by sidewall reflective walls, and the image sensing unit is provided with Light trapping structure. Furthermore, the upper surface of the image sensing unit is also provided with an anti-reflection structure.

[0056] Since the image sensing unit is equipped with a light trapping structure, the incident light is scattered to various angles after being reflected, scattered, and refracted by the light trapping structure. Together with the reflection effect of the side wall reflecting wall, the light in the image sensing unit can be extended. The effective optical length can significantly improve the absorption efficiency of near-infrared light without increasing the thickness of the silicon layer, and overcome the technical problem of low light absorption eff...

Embodiment 2

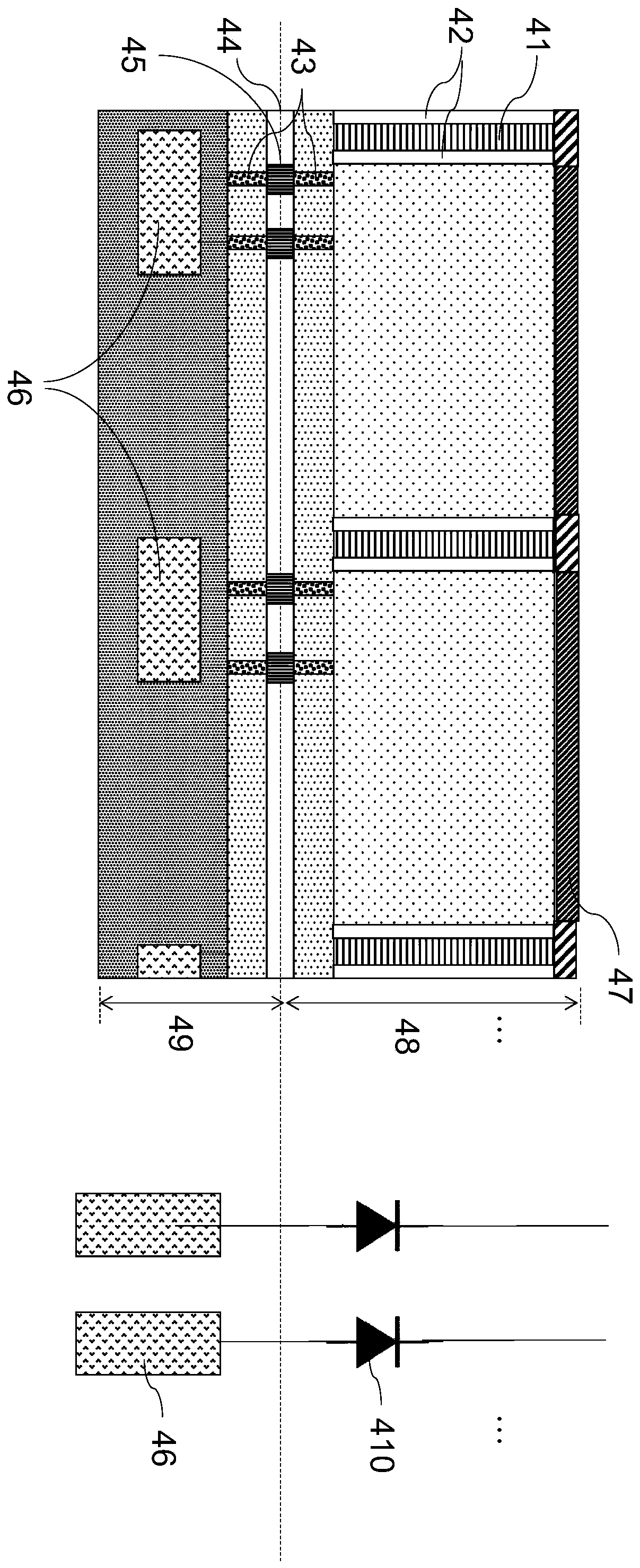

[0058] Based on the further improvement of embodiment 1, embodiment 2 is obtained. The light trapping structure is arranged on the upper surface of the image sensor unit and / or above the silicon oxide layer and / or below the silicon oxide layer, and the image sensor unit is separately arranged on the upper surface. The light trapping structure, the light trapping structure above the silicon oxide layer, or the light trapping structure below the silicon oxide layer can all improve the light absorption efficiency, and can also be used in combination. Further, the light-trapping structure is a nano-scale or micro-level uneven structure, for example, the light-trapping structure may be an inverted pyramid structure 1 (reference Figure 4 ) Or shallow trench structure 13 (e.g. Picture 10 As shown, the shallow groove structure 13 is provided on the upper surface of the image sensing unit), or the surface is a honeycomb surface, a sinusoidal grating textured surface, a dimple-like order...

Embodiment 3

[0062] Example 3 is obtained based on the further improvement of Example 1. Refer to Figure 8 , Figure 8 It is a schematic diagram of the cross-sectional structure of the third embodiment of an image sensing unit in the present invention; the light trapping structure and / or the antireflection structure is an inverted pyramid structure 1, and the inverted pyramid structure 1 has both light trapping and antireflection functions, specifically The inverted pyramid structure 1 is arranged on the upper surface of the image sensing unit (that is, arranged above the silicon detection layer 6), and the inverted pyramid structure 1 is obtained by filling silicon oxide after etching on a silicon substrate. In this embodiment, an insulating dielectric protective layer 5 is provided above the inverted pyramid structure 1 to protect the image sensor unit. Specifically, the inverted pyramid structure 1 arranged on the upper surface of the image sensing unit can form a gently gradual change i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com