Lithium ion battery anode material with high specific capacity and preparation method of lithium ion battery anode material

A lithium-ion battery and negative electrode material technology, applied in the direction of battery electrodes, carbon preparation/purification, secondary batteries, etc., can solve problems such as unsatisfactory requirements, and achieve the effects of facilitating immersion, increasing specific capacity, and ensuring stacking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Weigh 30g of hydroxide and 30g of sodium hydroxide, put them in a beaker, add 10mL of deionized water to stir and dissolve. Weigh 10 g of graphitized mesocarbon microspheres and add them to the alkali solution obtained above, and mix evenly. After the beaker containing the above mixture was baked in an oven at 60 °C for 24 h, the mixture was placed in a stainless steel tube furnace. Introduce argon gas as a protective gas, the gas flow rate is 50mL / min, the temperature is raised from room temperature to 700°C at a rate of 2°C / min, kept for 120min, and then naturally cooled to room temperature to obtain a heat-treated product. After washing 3 times with 5% dilute hydrochloric acid by mass percentage, clean it with a large amount of deionized water, and dry it. Get the product.

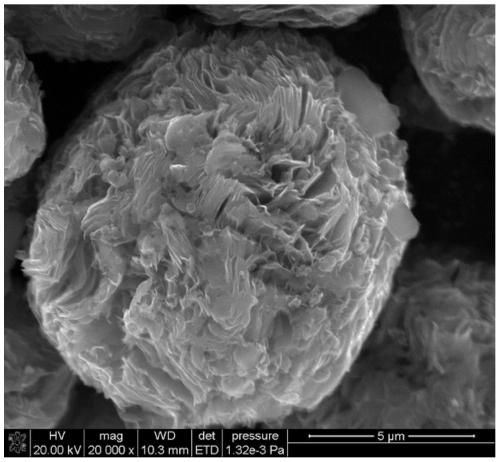

[0024] Lamellar spherical graphitized mesocarbon microspheres such as figure 1 shown. It can be seen from the figure that the mesophase carbon microspheres still maintain a spherical structur...

Embodiment 2

[0028] Weigh 10g of hydroxide and 20g of sodium hydroxide, put them in a beaker, add 10mL of deionized water to stir and dissolve. Weigh 10 g of graphitized mesocarbon microspheres and add them to the lye, and mix well. After the beaker containing the above mixture was baked in an oven at 60 °C for 24 h, the mixture was placed in a stainless steel tube furnace. Argon was introduced as a protective gas, the gas flow rate was 50mL / min, the temperature was raised from room temperature to 600°C at a rate of 5°C / min, kept for 180min, and then naturally cooled to room temperature to obtain a heat-treated product. After washing with 5% dilute hydrochloric acid for 3 times, it was cleaned with a large amount of deionized water and dried. Get the product.

Embodiment 3

[0030] Weigh 10g of hydroxide and 20g of sodium hydroxide, put them in a beaker, add 10mL of deionized water to stir and dissolve. Weigh 10 g of graphitized mesocarbon microspheres and add them to the lye, and mix well. After the beaker containing the above mixture was baked in an oven at 60 °C for 24 h, the mixture was placed in a stainless steel tube furnace. Introduce argon gas as a protective gas, the gas flow rate is 50mL / min, the temperature is raised from room temperature to 1000°C at a rate of 5°C / min, kept for 180min, and then naturally cooled to room temperature to obtain the heat-treated product. After washing with 10% dilute hydrochloric acid for 3 times, it was cleaned with a large amount of deionized water and dried. Get the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com