A method for synergistic and low-consumption removal of multi-pollutants in nitrogen fertilizer wastewater

A technology for pollutants and waste water, applied in the direction of water pollutants, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve the problems of high cost and high energy consumption, reduce energy consumption and material consumption, and improve process applicability Effects on sex and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

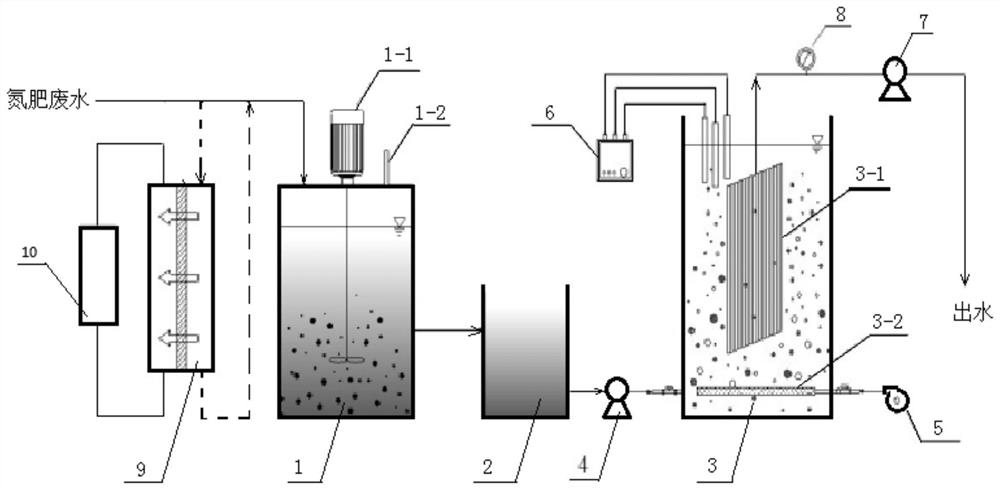

[0016] Specific embodiment one: the collaborative low-consumption method of this embodiment removes multi-pollutants in nitrogenous fertilizer wastewater, comprising the following steps:

[0017] 1. Nitrogen fertilizer wastewater is pumped into the anaerobic digestion reactor directly or after pretreatment. The reactor is a sealed sequencing batch reactor (SBR) with mechanical stirring and a gas collection device at the top; the reaction cycle is: Water for 0.5-1h, stirring for 20-24h, standing still for 0.5-1h, draining for 0.5-1h, water exchange ratio of 60%-80%; during operation, the temperature in the anaerobic digestion reactor is 20-40°C, and the pH is 7.0 ~8.0, the sludge concentration is 7000~9000mg / L; at this stage, 60~80% of organic matter and 70~90% of sulfur-containing pollutants in the wastewater are under the action of methanogenic bacteria and sulfate reducing bacteria in the sludge be removed;

[0018] 2. The effluent from the anaerobic digestion reactor enter...

specific Embodiment approach 2

[0020] Specific embodiment two: the difference between this embodiment and specific embodiment one is the pretreatment described in step one, when the anaerobic digestion section effluent COD of step one is higher than 80mg / L, enable the forward osmosis unit, first Low-concentration nitrogen fertilizer wastewater is concentrated; others are the same as the specific embodiment one.

specific Embodiment approach 3

[0021] Specific embodiment three: the difference between this embodiment and specific embodiment two is that the forward osmosis unit uses a cellulose triacetate (CTA) membrane with a thickness of 50-80 μm and a pore size of 0.2-0.35 nm as the permeable membrane; mol / L NaCl is used as the driving solution, and the concentration ratio is controlled at 2 to 5 times; the others are the same as in the second embodiment.

[0022] In this embodiment, the waste water is concentrated by relying on the pressure difference on both sides of the permeable membrane as the driving force.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com