Elastic insulation sole material and preparation process thereof

A shoe sole material and elastic technology, which is applied in the field of elastic insulating sole material and its preparation technology, can solve problems such as general wear resistance, sole slippage, and potential safety hazards, and achieve the effect of promoting softness and hardness, good elasticity, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] Embodiment 1: A kind of elastic insulating shoe sole material, the components included and their corresponding quality are shown in Table 1, and are prepared through the following steps:

[0077] Step 1, prepare thermoplastic polyurethane elastomer composite material:

[0078] A. Fully mix thermoplastic polyurethane elastomer, polyethylene, polypropylene, and ABS plastics after drying, and then mix them with 5-ethylidene-2-norbornene, vulcanization additives, halogen-free flame retardants, and calcium-zinc heat stabilizers additives, inorganic fillers, carbon black, fatty acid zinc, and halogen-free flame retardant synergists are fully mixed to obtain raw materials;

[0079] B. melting and mixing the raw materials obtained in step 1, and then extruding and granulating to obtain a soft thermoplastic polyurethane elastomer composite material;

[0080] Step 2, the soft thermoplastic polyurethane elastomer composite material obtained in step 1 and polyolefin thermoplastic ...

Embodiment 2-5

[0091] Embodiment 2-5: a kind of elastic insulation shoe sole material, the difference with embodiment 1 is that the components included and their corresponding quality are as shown in Table 1; the components included in the soft thermoplastic polyurethane elastomer composite material and their corresponding qualities are shown in Table 2.

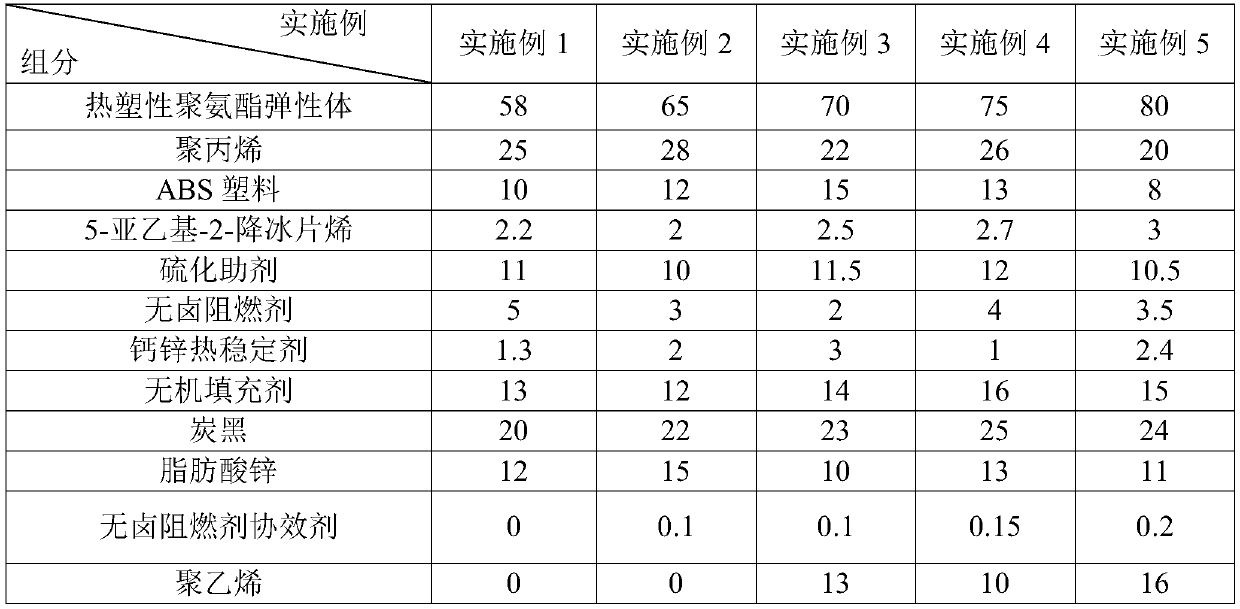

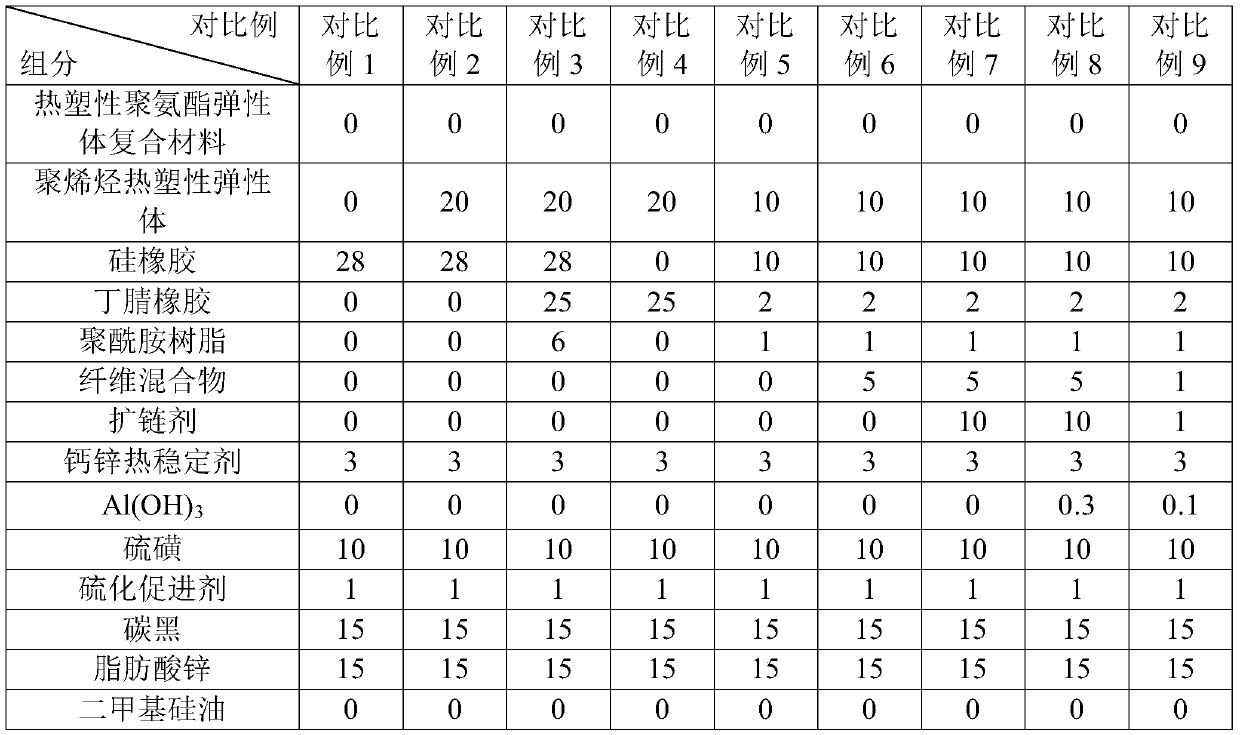

[0092] Components included in Table 1 Embodiment 1-5 and their corresponding mass (kg)

[0093]

[0094] Components included in the soft thermoplastic polyurethane elastomer composite material and their corresponding mass (kg) in the embodiment 1-5 of table 2

[0095]

Embodiment 6

[0096] Embodiment 6: An elastic insulating shoe sole material, the difference from Embodiment 1 is that the chain extender is DMTDA.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| activation index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com