High-strength martensitic stainless steel and manufacturing process thereof

A martensitic stainless steel, high-strength technology, applied in the field of stainless steel alloys, can solve the problems of unsatisfactory strength, poor cold forming performance, poor intergranular corrosion resistance, etc., and achieve good surface quality and flatness, good processing performance, Effect of improving strength and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

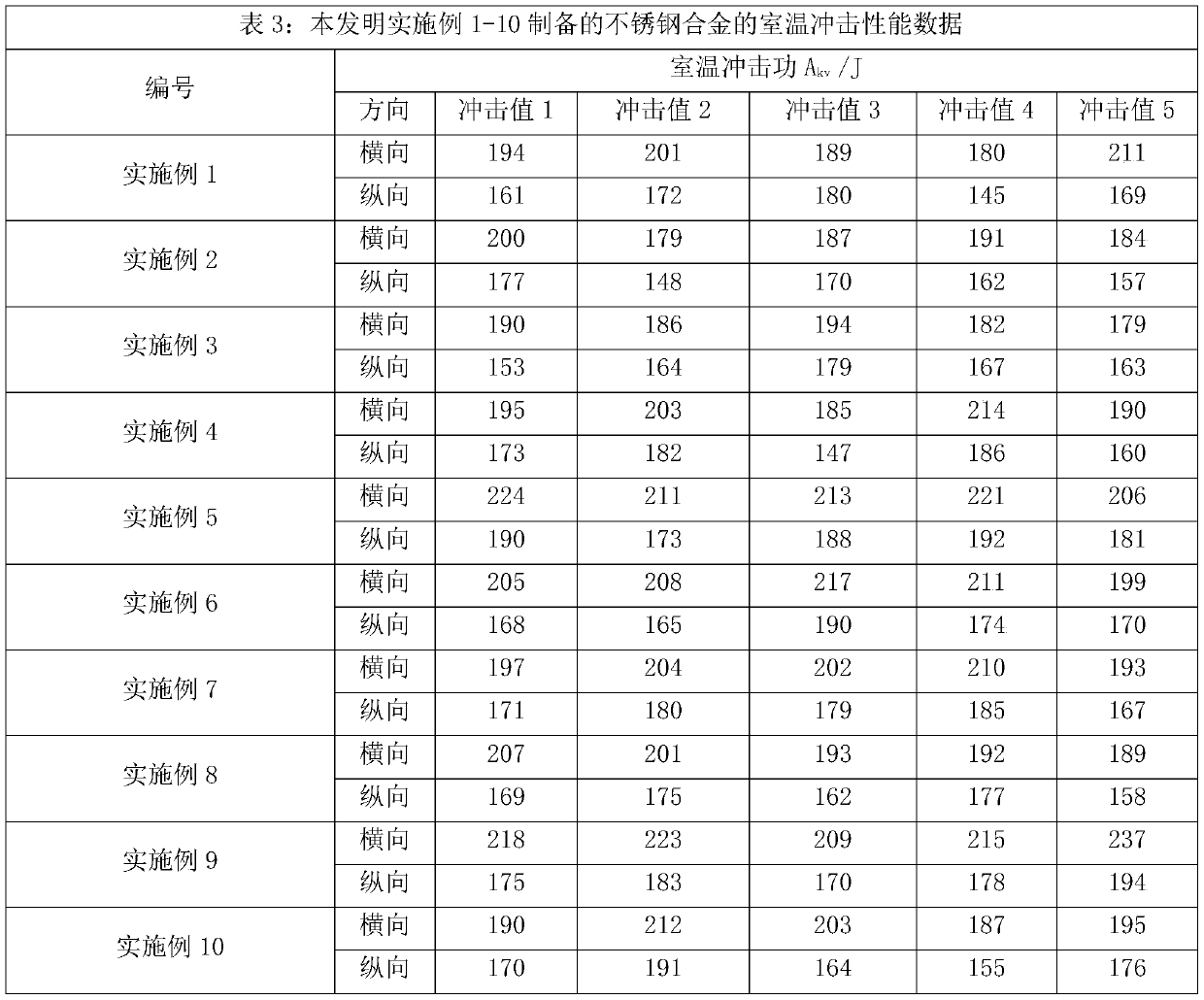

Examples

Embodiment 1-10

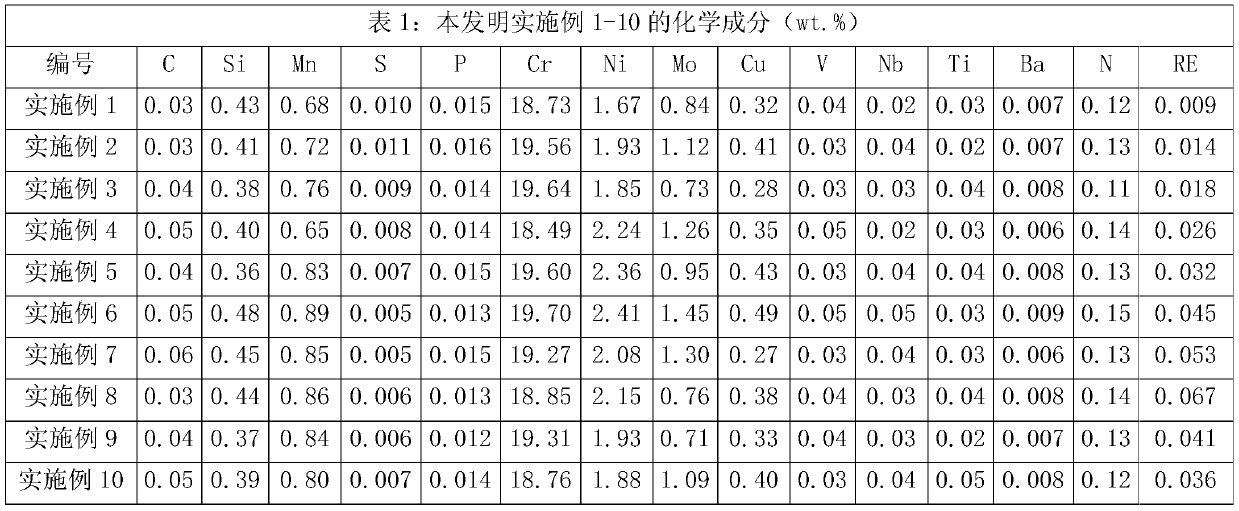

[0025] The composition of the high-strength martensitic stainless steel alloy in Examples 1-10 is shown in Table 1:

[0026]

[0027] The specific manufacturing method of stainless steel alloy is as follows:

[0028] (1) Smelting: Vacuum induction furnace, vacuum induction furnace and electroslag remelting, electric furnace and out-of-furnace refining, converter and out-of-furnace refining to smelt other components except rare earth elements, adding rare earth before tapping and casting Elements, the casting temperature is controlled at 1500-1650°C;

[0029] (2) Ingot or ingot billet opening: forging billet or continuous casting and rolling, heating temperature 1000-1250 ° C, initial forging temperature 1050-1200 ° C, final forging temperature 900-1050 ° C, solid solution after forging The treatment is to heat at 1050°C for 1-2h, then water-cooled.

[0030] (3) Hot rolling: the billet heating temperature is 1000-1250°C, the rolling start temperature is 1050-1200°C, the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com