Volatile organic compound (VOCs) waste gas resource utilization method and device

A technology for organic volatiles and waste gas, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles. The effect of loss volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

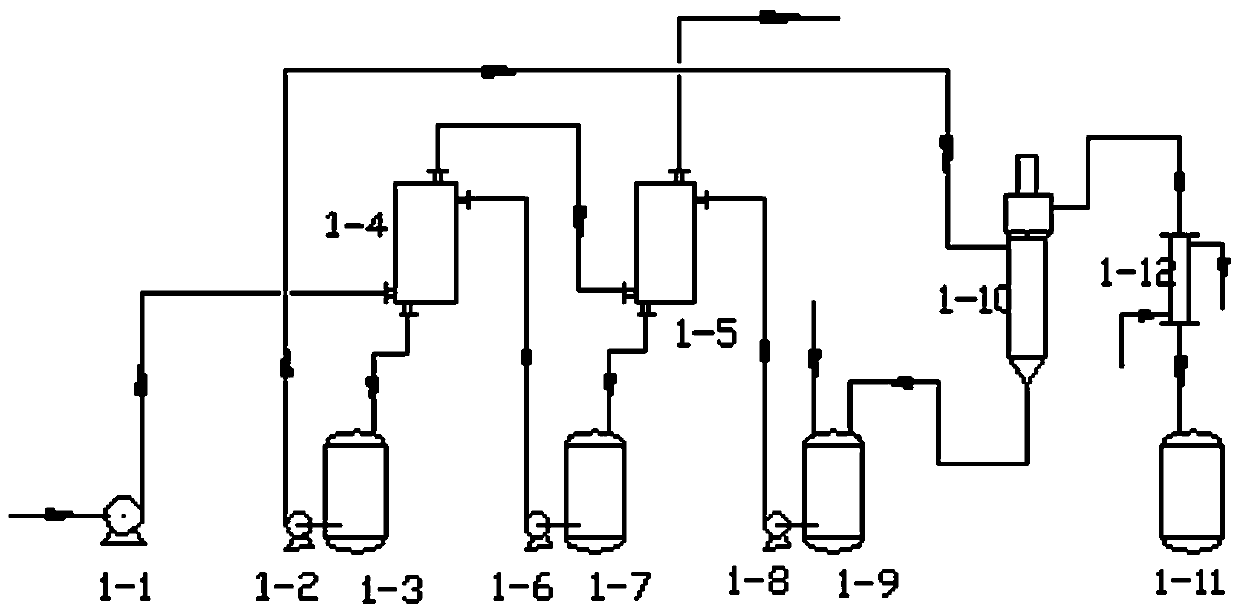

[0034] The VOCs composition of industrial waste gas is toluene 650mg / m 3 , Benzene 1050 mg / m 3 , xylene 410 mg / m 3 ; The absorbent ionic liquid is 1-butyl-3-methylimidazolium tetrafluoroborate, with a melting point of -82°C, a density of 1.17g / ml, and a viscosity of 233cP. Put the absorbent into the fresh absorbent storage tank 1-9, the amount of the added absorbent is always kept at the upper limit of the liquid level of the fresh absorbent storage tank 1-9, the temperature of the absorbent is controlled at 10-15°C, and the second-stage and second-stage Micro-mixing reactor 1-5, after the operation is stable, start fresh absorbent circulation pump 1-8, flow control 2000L / h, after 1-7 in the secondary absorbent storage tank reaches the upper limit of the absorbent liquid level, start a First-stage second-stage micro-mixing reactor 1-4, after the operation is stable, turn on the second-stage circulating pump 1-6 to control the flow rate of 2000L / h, and turn on the absorbent a...

Embodiment 2

[0036] The VOCs composition of industrial waste gas is n-hexane 777mg / m 3 , pentadiene 380 mg / m 3 , Isooctane 210 mg / m 3 ; The absorbent ionic liquid is 1-butyl-3-methylimidazolium hexafluorophosphate, with a melting point of -8°C, a density of 1.36g / ml, and a viscosity of 312cP. Operate according to the process in Example 1, the temperature of the absorbent is controlled at 20°C, the flow rate of the absorbent is controlled at 1000L / h, and the air volume of the gas is 1000m 3 / h, the temperature of the film scraper evaporator is 80°C, and the vacuum degree is 20-30Kpa. The VOC content in the exhaust gas after treatment is 32mg / m of n-hexane 3 , pentadiene 58mg / m 3 , Isooctane 14.5 mg / m 3

Embodiment 3

[0038] The VOCs composition of industrial waste gas is methanol 2100mg / m 3 , ethanol 1100 mg / m 3 , ethyl acetate 530 mg / m 3 ; The absorbent ionic liquid is 1-propyl-3-methylimidazolium hexafluorophosphate, with a melting point of 40°C. Operate according to the process in Example 1, the temperature of the absorbent is controlled at 60°C, the flow rate of the absorbent is controlled at 2000L / h, and the air volume of the gas is 500m 3 / h, the temperature of the film scraper evaporator is 100°C, and the vacuum degree is 30-35Kpa. The VOC content in the exhaust gas after treatment is methanol 106mg / m 3 , ethanol 65 mg / m 3 , ethyl acetate 25 mg / m 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap