A kind of cbn resin bond abrasive tool and preparation method thereof

A bonding agent and resin technology, used in grinding/polishing equipment, abrasives, grinding devices, etc., can solve the problems of low grinding efficiency, poor shape and position accuracy of grinding objects and poor surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

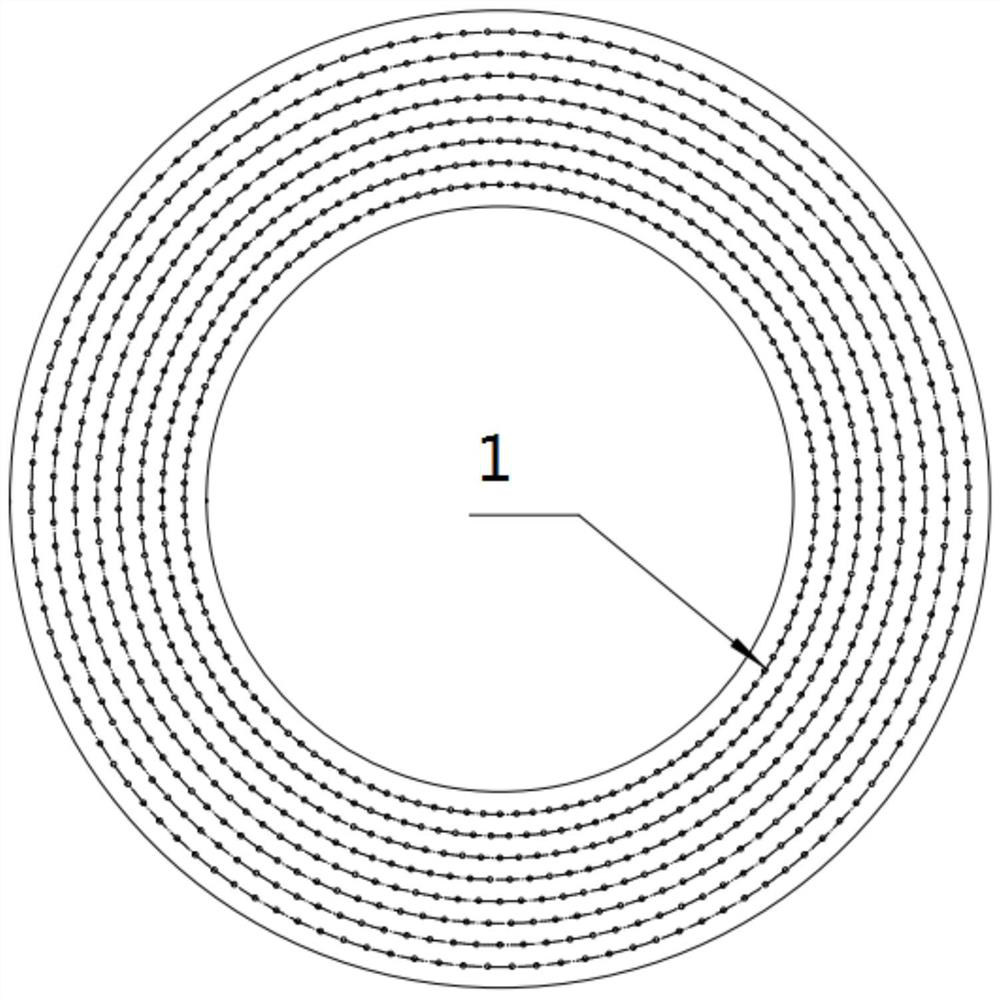

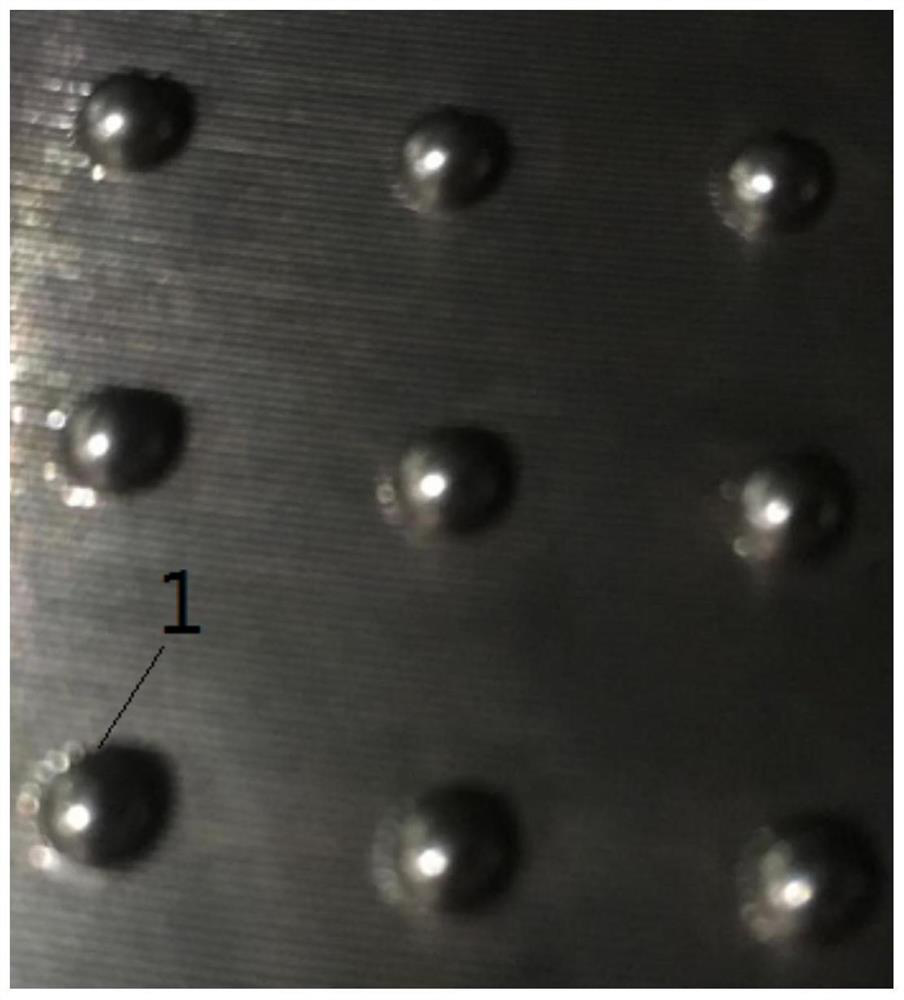

Image

Examples

Embodiment 1

[0042] The CBN resin bond abrasive tool of the present embodiment is a grinding disc, made of the following raw materials in mass percentage: 10% of thermosetting resin, 25% of cubic boron nitride, 40% of metal powder, 5% of green silicon carbide, 10% of calcium sulfate whisker %, solid lubricant 10%; the average particle size of cubic boron nitride is 90 μm, the metal powder is iron powder with an average particle size of 15 μm, the average particle size of green silicon carbide is 10 μm, and the average length of calcium sulfate whiskers is 30 μm , the average diameter of calcium sulfate whiskers is 4 μm, and the solid lubricant is graphite powder with an average particle diameter of 25 μm.

Embodiment 2

[0044] The CBN resin bond abrasive tool of the present embodiment is a grinding disc, made of the following raw materials in mass percentage: 20% thermosetting resin, 10% cubic boron nitride, 37% metal powder, 15% green silicon carbide, calcium sulfate whisker 3 %, solid lubricant 5%; the average particle size of cubic boron nitride is 90 μm, the metal powder is iron powder with an average particle size of 20 μm, the average particle size of green silicon carbide is 40 μm, and the average length of calcium sulfate whiskers is 46 μm. The average diameter of calcium sulfate whiskers is 6 μm, and the solid lubricant is graphite powder with an average particle diameter of 38 μm.

Embodiment 3

[0046] The CBN resin bond abrasive tool of the present embodiment is a grinding disc, made of the following raw materials in mass percentage: 20% of thermosetting resin, 25% of cubic boron nitride, 20% of metal powder, 15% of green silicon carbide, 10% of calcium sulfate whisker %, solid lubricant 10%; the average particle size of cubic boron nitride is 125 μm, the metal powder is iron powder with an average particle size of 23 μm, the average particle size of green silicon carbide is 25 μm, and the average length of calcium sulfate whiskers is 60 μm , the average diameter of calcium sulfate whiskers is 15 μm, and the solid lubricant is graphite powder with an average particle size of 38 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com