Polyethylene-titanium oxide micro-nano multi-level structure composite microsphere material and its application

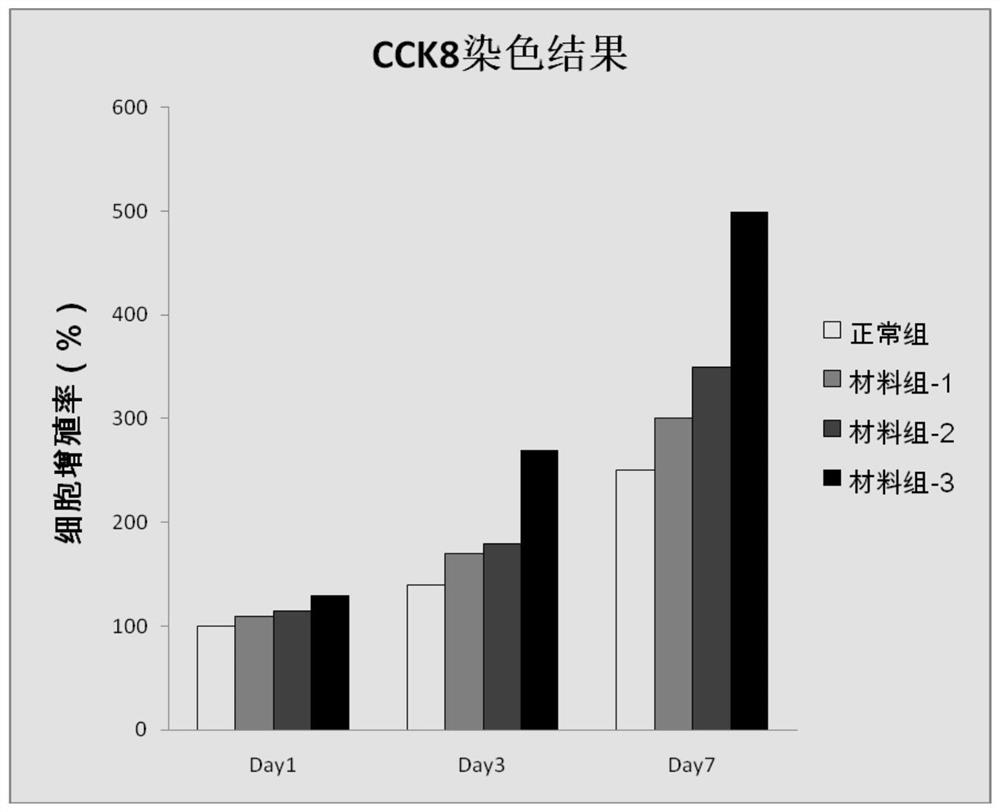

A polyethylene microsphere, micron-nano technology, applied in the field of biomedical engineering, can solve the problems of uncontrollable embryonic stem cell differentiation, teratoma, non-localization, etc., and achieve the effects of good differentiation potential, promotion of proliferation, and controllable shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

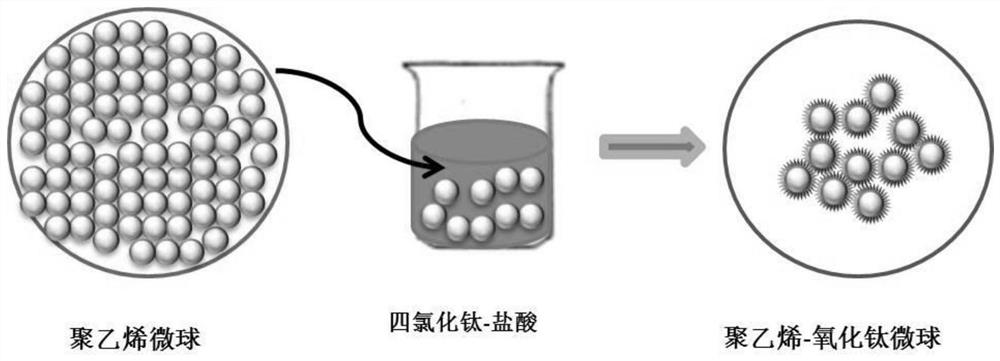

[0033] In one embodiment of the present invention, the preparation method ( figure 1 ), including the following steps:

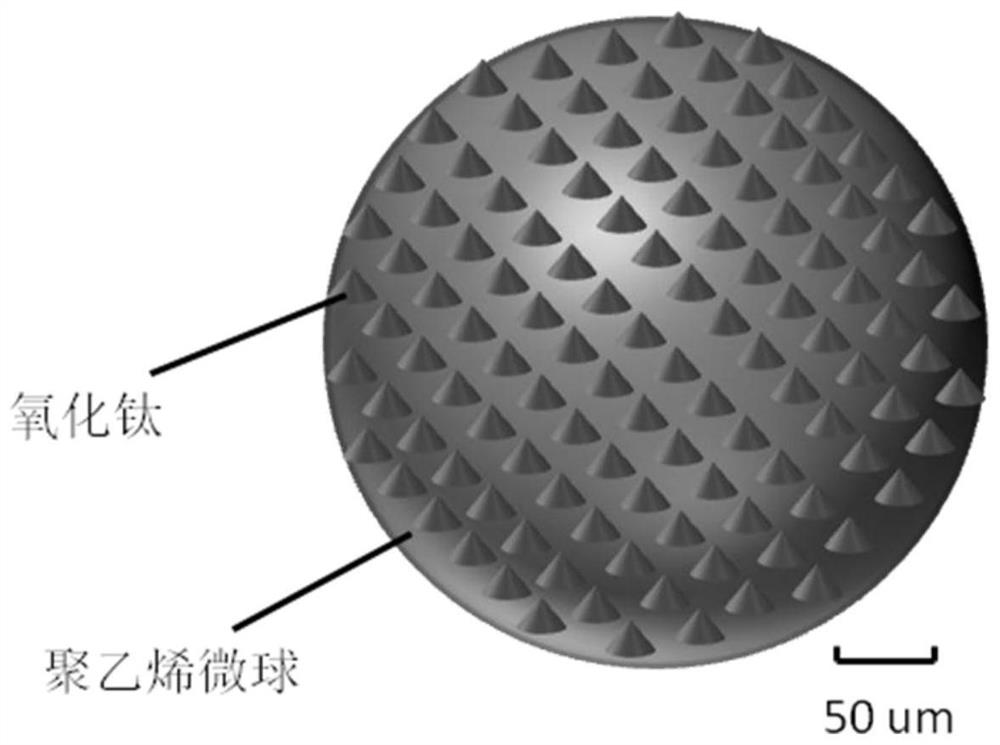

[0034] Immerse polyethylene microspheres in titanium tetrachloride-hydrochloric acid solution, soak in a constant temperature water bath at 60-100°C for 4-24 hours with stirring, harvest the microspheres, wash them with deionized water three times, then wash them with absolute ethanol, and dry them. dry to obtain polyethylene microspheres coated with titanium oxide nanostructures ( figure 2 ).

[0035] In the preparation method of the polyethylene-titanium oxide micro-nano multi-level structure composite microsphere material of the present invention, each step complements each other and forms an organic whole. In the invention, micron-sized polyethylene microspheres are reacted in a titanium tetrachloride-hydrochloric acid solution with a specific concentration and ratio, and nanometer-sized titanium oxide can be grown on the surface of the polyethylene m...

Embodiment 1

[0039] Example 1: Preparation of polyethylene-titanium oxide micro-nano hierarchical structure composite microsphere material

[0040] Polyethylene microspheres (80 μm in diameter) were immersed in the titanium tetrachloride-hydrochloric acid solution (the titanium tetrachloride-hydrochloric acid mixed solution was prepared by the following method: 10ml of titanium tetrachloride was added dropwise to a concentration of 0.1 mol / L hydrochloric acid solution (10ml), prepare titanium tetrachloride-hydrochloric acid mixed solution), stir in 80 ℃ constant temperature water bath (stirring speed is 200rpm) react 12h, harvest microsphere, wash three times with deionized water, and then After cleaning with absolute ethanol, drying and drying, the polyethylene-titanium oxide micro-nano multi-level structure composite microsphere material is prepared.

Embodiment 2

[0041]Example 2: Preparation of polyethylene-titanium oxide micro-nano hierarchical structure composite microsphere material

[0042] Polyethylene microspheres (500 μm in diameter) were immersed in titanium tetrachloride-hydrochloric acid solution (the mixed solution of titanium tetrachloride-hydrochloric acid was prepared by the following method: 10ml titanium tetrachloride was added dropwise to a concentration of 0.25 mol / L hydrochloric acid solution (10ml), prepare titanium tetrachloride-hydrochloric acid mixed solution), stir in 60 ℃ constant temperature water bath (stirring speed is 100rpm) react 24h, harvest microsphere, wash three times with deionized water, and then After cleaning with absolute ethanol, drying and drying, the polyethylene-titanium oxide micro-nano multi-level structure composite microsphere material is prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com