A method for directly preparing mesoporous silicon-magnesium composite oxide fibers by electrospinning

A composite oxide and electrospinning technology, which is applied in the direction of inorganic raw material artificial filaments, etc., can solve the problems of difficult to obtain water-based silicon-magnesium sol, etc., and achieve the effect of simple heat treatment, strong flexibility and high purity of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] A method for directly preparing mesoporous silicon-magnesium composite oxide fibers by electrospinning, comprising the following steps:

[0071] (1) Preparation of silicon magnesium sol spinning solution

[0072] (i) citric acid, water, and ethanol are made into acid X: water: a citric acid / water / alcohol solution with a molar ratio of water: ethanol of 0.01:6:2 to obtain acidic hydrolysis catalytic solution CA62.

[0073] (ii) Dissolve 6g of PVA in 94g of ethanol with a mass fraction of 30% ethanol in aqueous solution, stir until the PVA is completely dissolved to obtain the spinning aid solution "PVA630", add 3.644g of CTAB to it, stir until dissolved to obtain "PVA630-3" .

[0074] (iii) 20 g of the hydrolysis catalytic solution CA was added dropwise to 20.833 g of tetraethyl orthosilicate (TEOS) under magnetic stirring, and the stirring was continued for 6 hours to allow the hydrolysis reaction to fully proceed to obtain a hydrolyzed silica sol.

[0075] (iv) Add 6...

Embodiment 2

[0083] A method for directly preparing mesoporous silicon-magnesium composite oxide fibers by electrospinning, comprising the following steps:

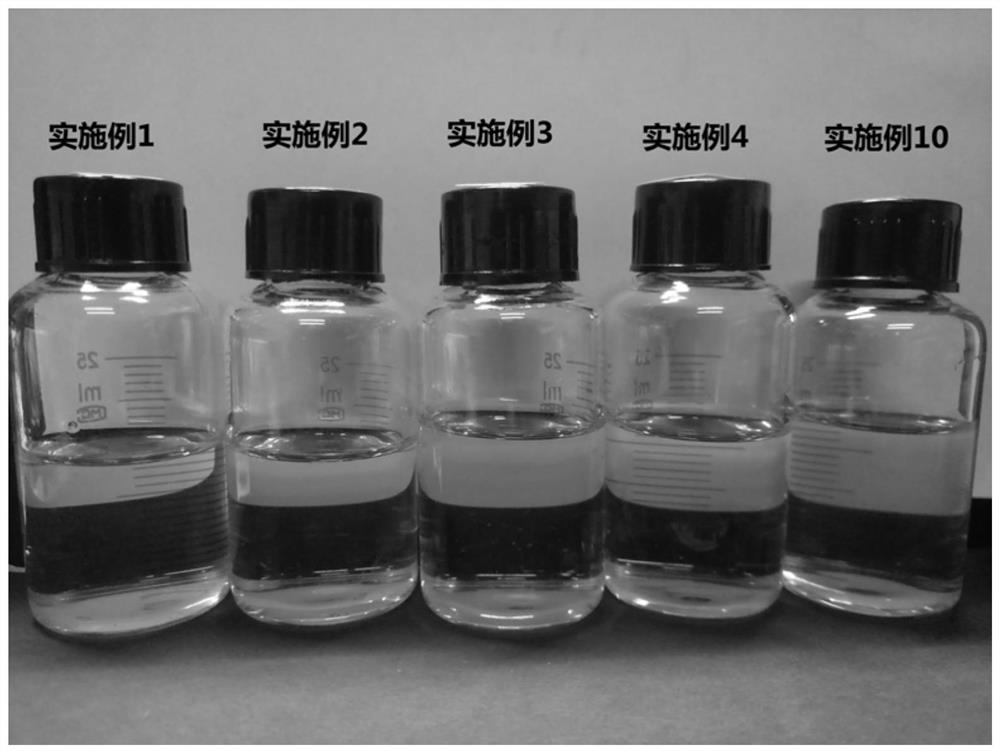

[0084] As described in Example 1, the difference is that in step (1), phosphoric acid, water and ethanol are made into phosphoric acid: water: the mol ratio of ethanol is 0.01:6:2 X acid / water / alcohol solution to obtain acidic Hydrolysis catalytic solution PA62. Get the precursor spinning solution, such as figure 1 shown.

Embodiment 3

[0086] A method for directly preparing mesoporous silicon-magnesium composite oxide fibers by electrospinning, comprising the following steps:

[0087] As described in Example 1, the difference is that in step (1), citric acid, water, and ethanol are made into citric acid: the mol ratio of water is an aqueous citric acid solution of 0.01:11 to obtain acidic hydrolysis catalytic solution CA0. Dissolve 6g of PVA in 94g of water, stir until the PVA is completely dissolved to obtain the spinning aid solution "PVA6", such as figure 1 Shown; Carry out spinning, obtain the silicon-magnesium composite oxide fiber that does not possess high specific surface area.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com