Energy-saving emission-reduction diesel oil emulsifying method

A technology for energy saving, emission reduction, and diesel oil, which is applied in the petroleum industry, adding non-fuel substances to fuel, and liquid carbon-containing fuels. It can solve problems such as oil-water separation, unsatisfactory emulsification effect, and corrosion of high-pressure nozzles of diesel engines, so as to reduce NOX and The emission of PM soot, the solution to poor emulsification effect, and the effect of improving combustion thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The energy-saving and emission-reducing diesel emulsification method disclosed in this embodiment specifically includes the following steps:

[0031] (1) Prepare the emulsifying additive in proportion: the emulsifying additive is mixed by the following raw materials in parts by weight: 0.1 part of potassium nitrate, 0.1 part of potassium bicarbonate, 10 parts of urea, 0.5 part of sodium nitrite, 0.1 part of sodium hydroxide, poly 0.7 parts of vinyl alcohol, 0.1 parts of triethanolamine, 2 parts of Span 80, 0.25 parts of Tween 20, and 100 parts of pure water. Vinyl alcohol, triethanolamine, Span 80, and Tween 20 are poured into the reaction kettle with pure water in sequence according to the ratio, and fully mixed;

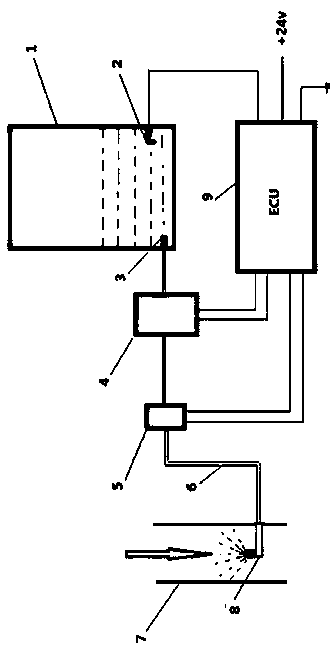

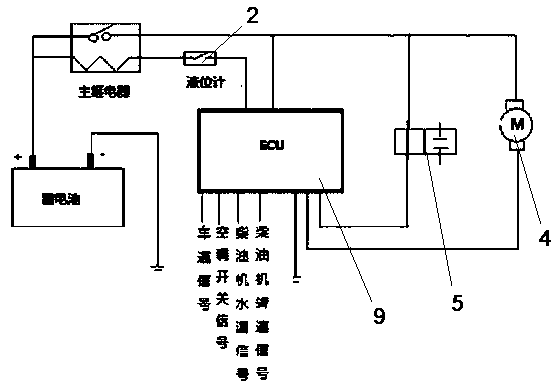

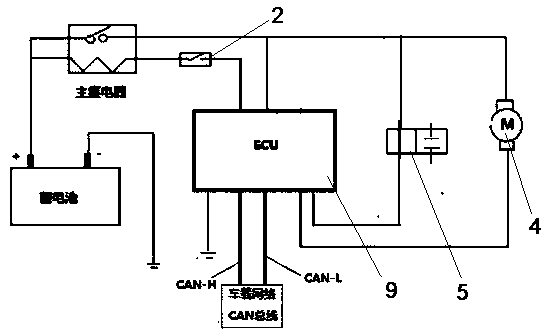

[0032] (2) Equipment preparation: such as figure 1As shown, a high-pressure atomizing nozzle 8 is installed on the intake manifold 7 of the diesel engine, and the high-pressure atomizing nozzle 8 is located on the intake manifold 7 of the diesel engine. Th...

Embodiment 2

[0043] Except for the following differences, all the others are the same as in Example 1.

[0044] The energy-saving and emission-reducing diesel oil emulsifying additive of the present embodiment is an emulsifying additive for diesel oil in the prior art, such as the emulsifying diesel oil additive (A-55) of Voerle Science and Technology Enterprise Group.

Embodiment 3

[0046] The energy-saving and emission-reducing diesel emulsifying additive of the present embodiment is formed by mixing the following raw materials in parts by weight: 0.5 part of potassium nitrate, 0.5 part of potassium bicarbonate, 12 parts of urea, 0.1 part of sodium nitrite, 0.2 part of sodium hydroxide, polyethylene 0.75 parts of alcohol, 0.5 parts of triethanolamine, 1 part of Span 80, 0.5 parts of Tween 20, and 100 parts of water.

[0047] The emulsification method of the present application is compared with the diesel oil that has been emulsified, and only sprayed diesel oil without emulsifying additives, namely:

[0048] Group A: The additive composition and formulation are as described in Example 1 of the present application, the diesel emulsification method is also as described in Example 1 of the present application, and the dosage ratio of additives to diesel is 1:5 by weight;

[0049] Group B: Additive components and formulations are as described in Example 1 of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com