Organic photoelectric detector and preparation method thereof

A photodetector, organic technology, applied in photovoltaic power generation, electro-solid device, semiconductor/solid-state device manufacturing, etc., can solve the problems of low external quantum efficiency and weak photomultiplier effect, and achieve the improvement of specific detection rate and photo-generated current. , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

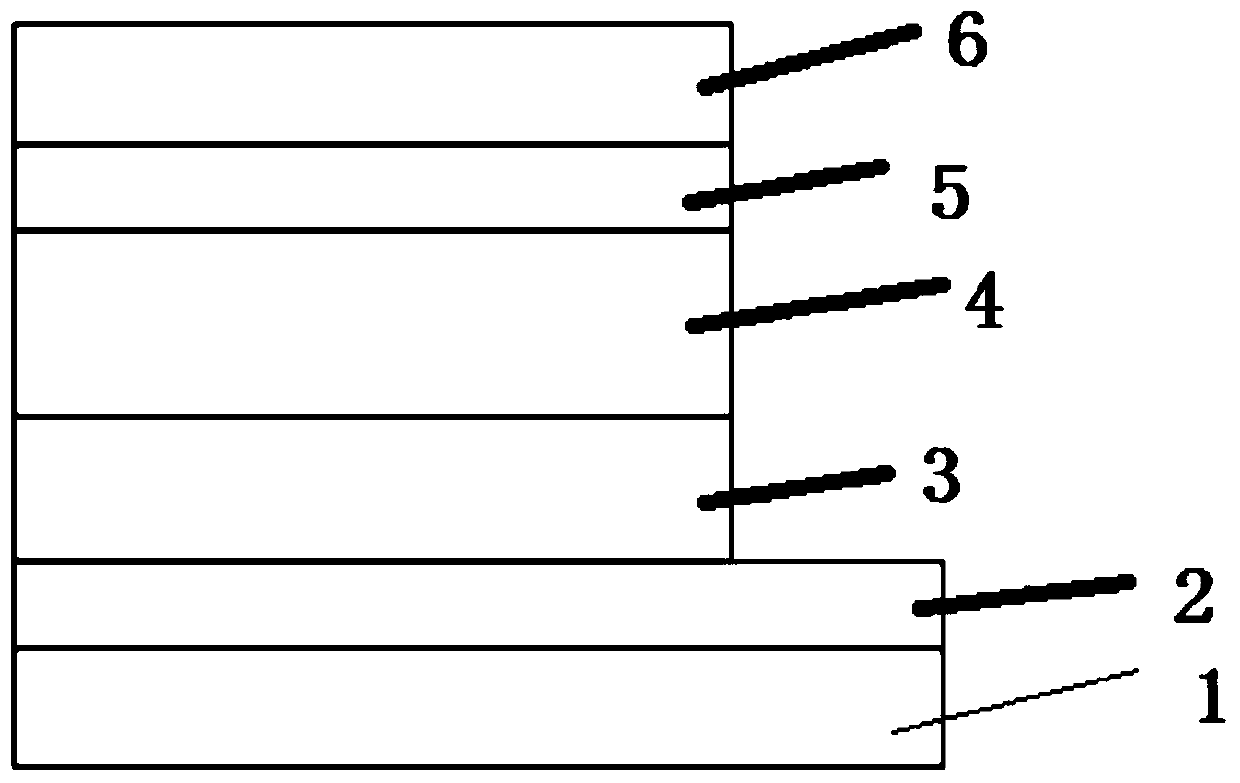

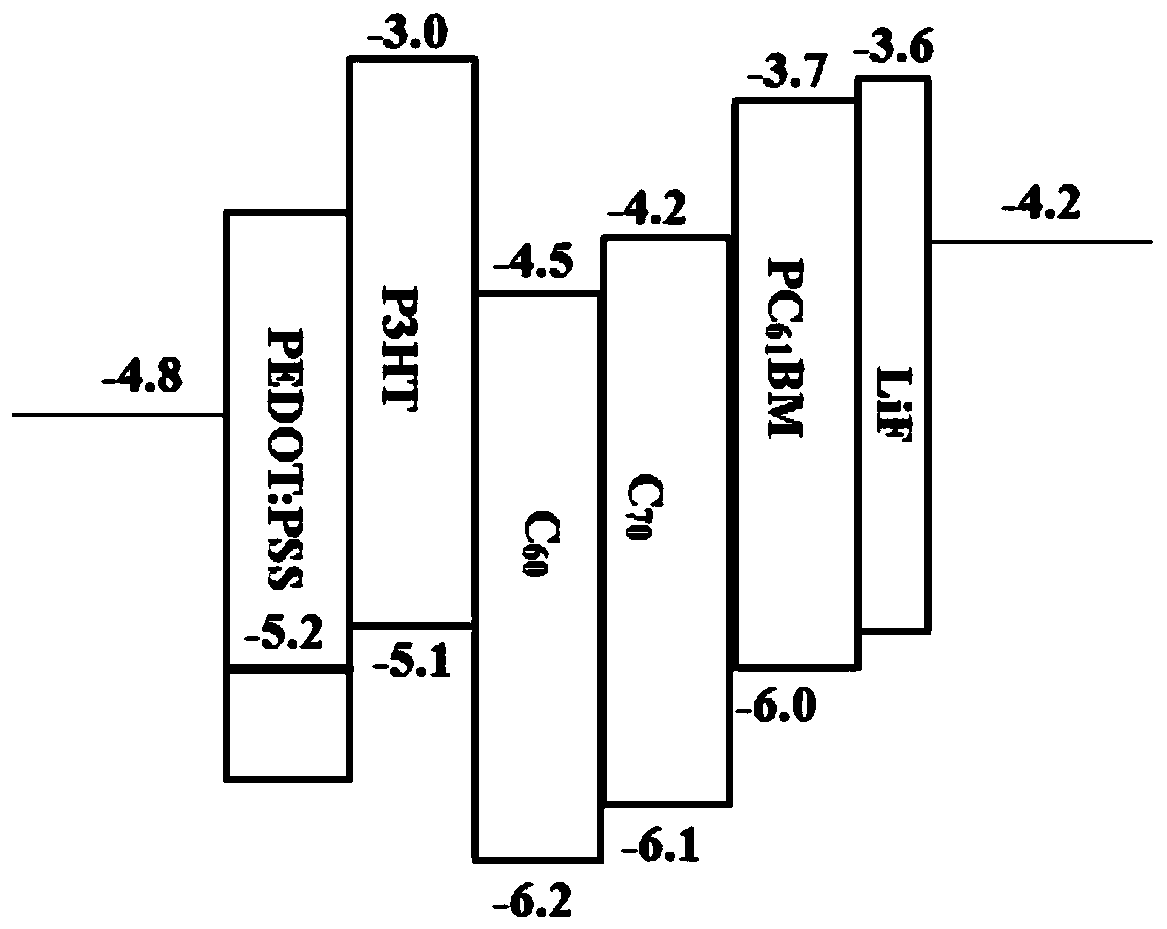

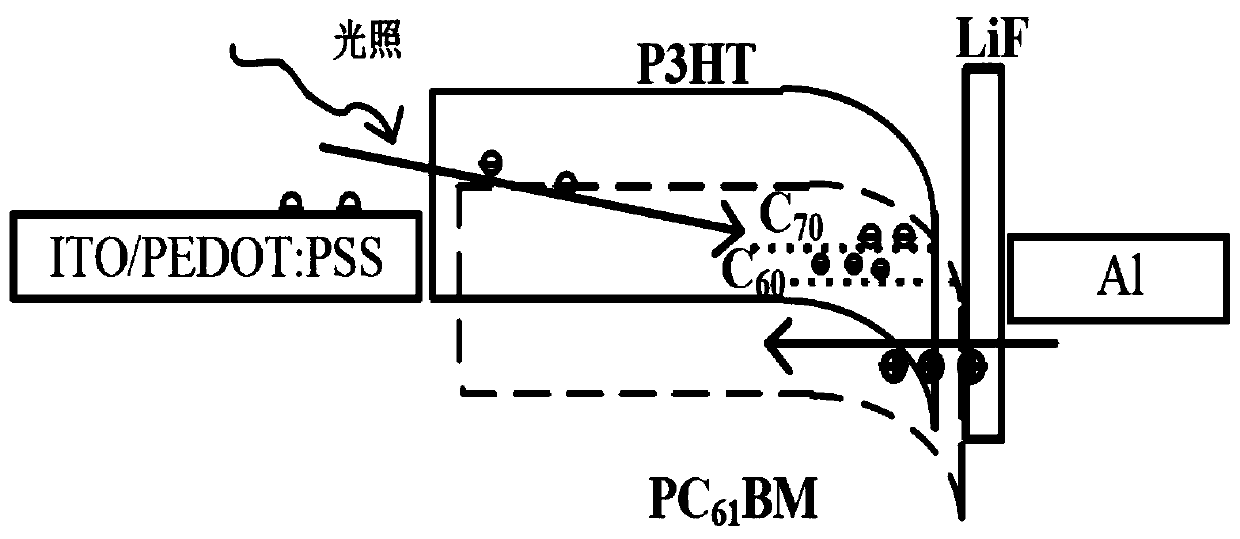

[0041] A method for preparing an organic photodetector, comprising the steps of:

[0042] Step 1. First coat the ITO electrode layer 2 on the glass substrate 1, and then clean the glass substrate 1. First, use deionized water to ultrasonically clean the glass substrate 1 for 15 minutes to 20 minutes, and then use acetone to clean the glass substrate 1. 2 Perform ultrasonic cleaning for 15-20 minutes, and finally use anhydrous ethanol to ultrasonically clean for 15-20 minutes, then blow dry with pure nitrogen or infrared oven.

[0043] Step 2, after the glass substrate 1 treated in step 1 is cleaned with ultraviolet ozone light, it is placed in a nitrogen glove box, and the mixture of PEDOT and PSS is spin-coated on the surface of the ITO electrode layer 2 by a glue homogenizer; spin coating After completion, the glass substrate 1 is annealed to form an anode buffer layer 3 with a thickness of 30 nm to 50 nm;

[0044] The spin-coating rate is 3000rpm-3500rpm, the spin-coating ...

Embodiment 1

[0051] Step 1. First coat the ITO electrode layer 2 on the glass substrate 1, and then clean the glass substrate 1. First, use deionized water to ultrasonically clean the glass substrate 1 for 15 minutes, and then use acetone to clean the glass substrate 2. Ultrasonic cleaning for 15min, and finally ultrasonic cleaning with absolute ethanol for 15min, and then drying with pure nitrogen or infrared drying.

[0052] Step 2, after the glass substrate 1 treated in step 1 is cleaned with ultraviolet ozone light, it is placed in a nitrogen glove box, and the mixture of PEDOT and PSS is spin-coated on the surface of the ITO electrode layer 2 by a glue homogenizer; spin coating After completion, the glass substrate 1 is annealed to form an anode buffer layer 3 with a thickness of 45 nm;

[0053] The spin-coating rate is 3000rpm, and the spin-coating time is 60s; the annealing temperature is 120°C, and the annealing time is 15min.

[0054] Step 3, first connect P3HT, PC 61 BM, C 60 ...

Embodiment 2

[0059] Step 1. First coat the ITO electrode layer 2 on the glass substrate 1, and then clean the glass substrate 1. First, use deionized water to ultrasonically clean the glass substrate 1 for 15 minutes, and then use acetone to clean the glass substrate 2. Ultrasonic cleaning for 15 minutes, and finally using anhydrous ethanol ultrasonic cleaning for 15 minutes, and then drying with pure nitrogen or infrared drying.

[0060] Step 2, after the glass substrate 1 treated in step 1 is cleaned with ultraviolet ozone light, it is placed in a nitrogen glove box, and the mixture of PEDOT and PSS is spin-coated on the surface of the ITO electrode layer 2 by a glue homogenizer; spin coating After completion, the glass substrate 1 is annealed to form an anode buffer layer 3 with a thickness of 40 nm;

[0061] The spin-coating rate is 3200rpm, and the spin-coating time is 60s; the annealing temperature is 120°C, and the annealing time is 15min.

[0062] Step 3, first connect P3HT, PC 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com