Quaternary broad-spectrum high-specific-detectivity organic photoelectric detector and preparation method thereof

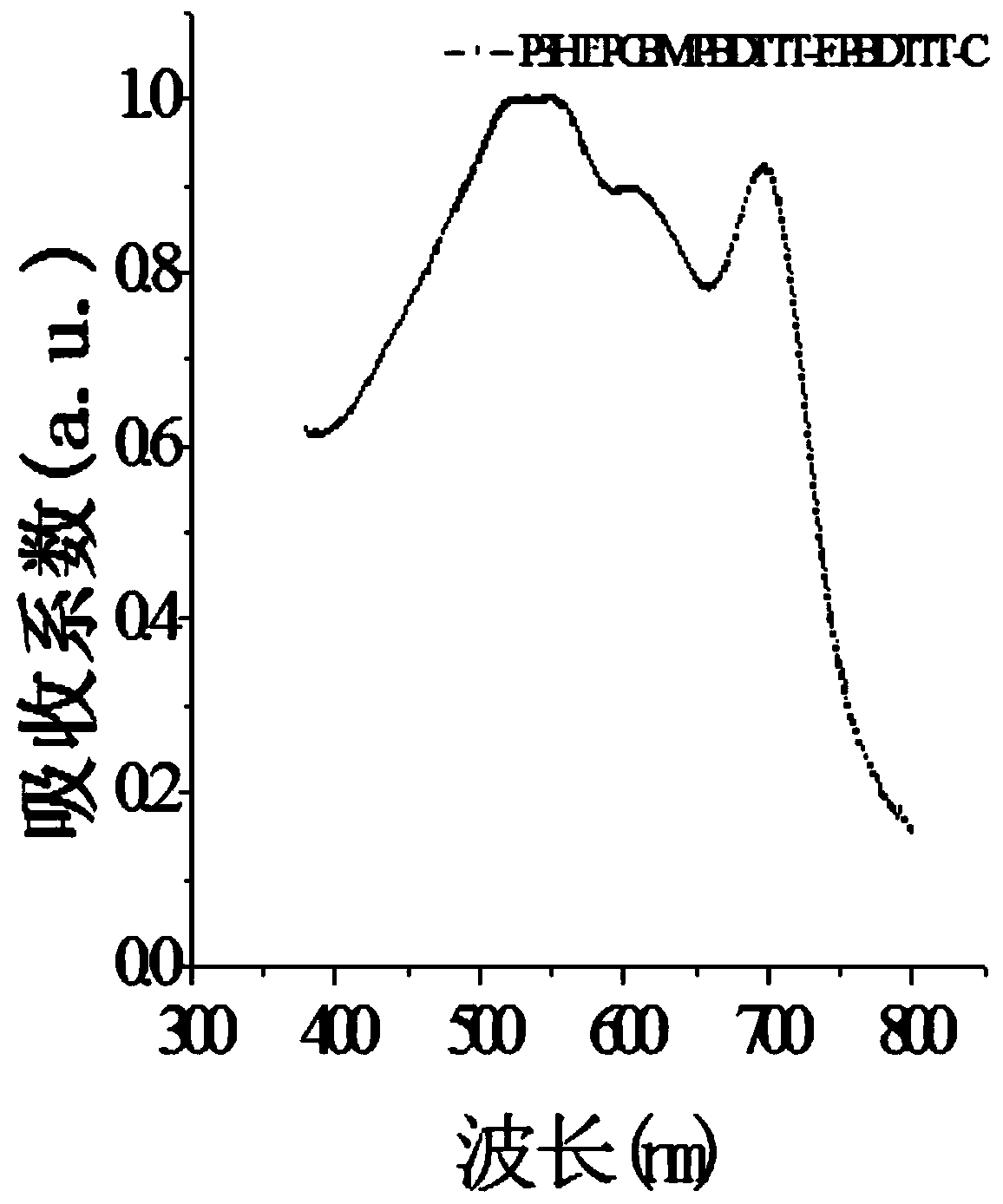

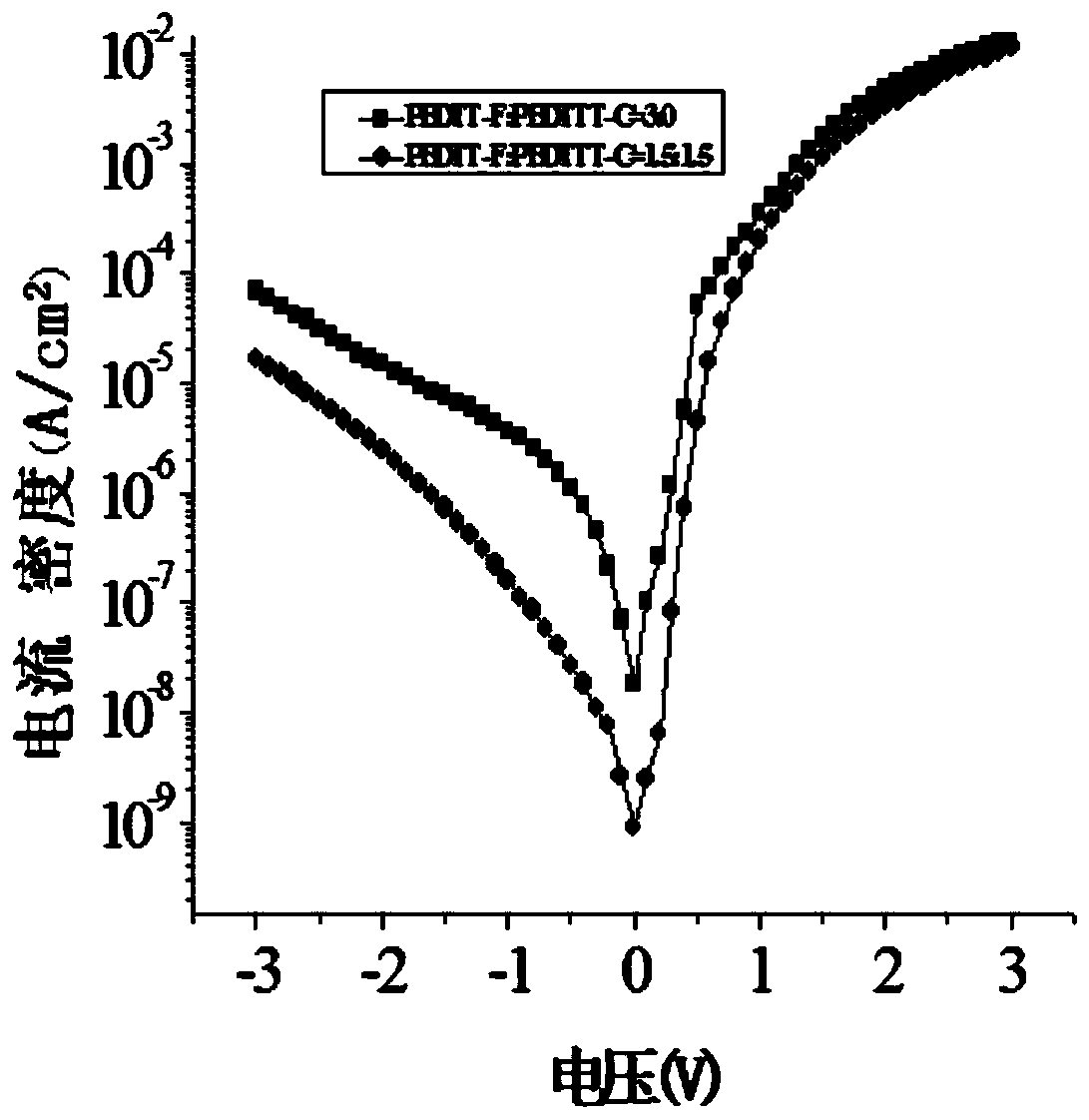

A photodetector and detection rate technology, which is applied in photovoltaic power generation, electrical solid-state devices, semiconductor/solid-state device manufacturing, etc., can solve the problems of high preparation process requirements, narrow spectral response range, low detection rate and linear dynamic range, etc. Achieve the effect of expanding the spectral response range, increasing the exciton dissociation rate, and promoting the absorption of visible light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

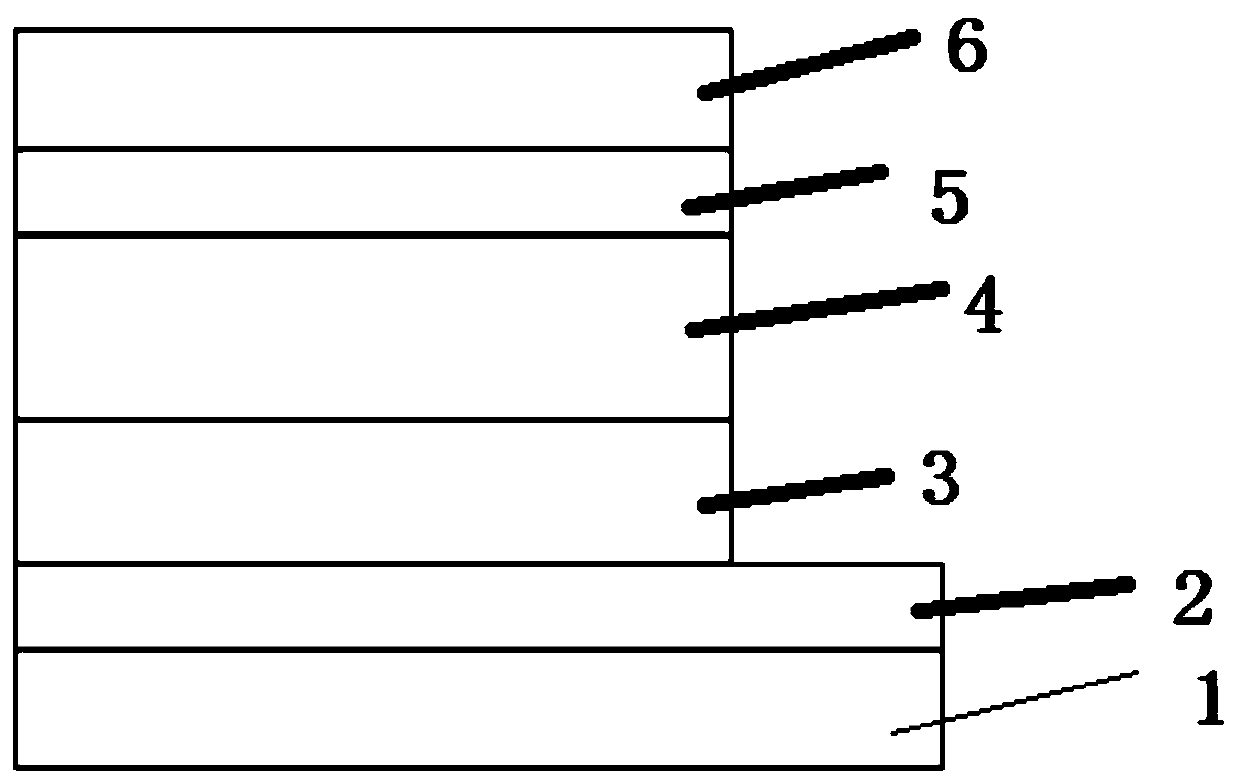

[0052] The preparation method of the quaternary wide spectrum high specific detectivity organic photodetector is specifically carried out according to the following steps:

[0053] Step 1, first plate the ITO electrode layer 2 on the glass substrate 1, then use deionized water to ultrasonically clean the glass substrate 1 with the ITO electrode layer 2 for 15 minutes, and then use acetone to clean the glass substrate of the ITO electrode layer 2. 1. Perform ultrasonic cleaning for 15 minutes, and finally use absolute ethanol to perform ultrasonic cleaning on the glass substrate 1 of the ITO electrode layer 2 for 15 minutes, and then dry it with pure nitrogen or infrared to obtain the glass substrate 1 coated with the ITO electrode layer 2;

[0054] Step 2, after the glass substrate 1 coated with the ITO electrode layer 2 is cleaned with ultraviolet ozone light, it is placed in a nitrogen glove box, and the PEDOT:PSS mixture is spin-coated on the surface of the ITO electrode lay...

Embodiment 2

[0062] The preparation method of the quaternary wide spectrum high specific detectivity organic photodetector is specifically carried out according to the following steps:

[0063] Step 1, first plate the ITO electrode layer 2 on the glass substrate 1, then use deionized water to ultrasonically clean the glass substrate 1 with the ITO electrode layer 2 for 20 minutes, and then use acetone to clean the glass substrate of the ITO electrode layer 2. 1. Perform ultrasonic cleaning for 20 minutes, and finally use absolute ethanol to perform ultrasonic cleaning on the glass substrate 1 of the ITO electrode layer 2 for 20 minutes, and then dry it with pure nitrogen or infrared to obtain the glass substrate 1 coated with the ITO electrode layer 2;

[0064] Step 2, after the glass substrate 1 coated with the ITO electrode layer 2 is cleaned with ultraviolet ozone light, it is placed in a nitrogen glove box, and the PEDOT:PSS mixture is spin-coated on the surface of the ITO electrode lay...

Embodiment 3

[0072] The preparation method of the quaternary wide spectrum high specific detectivity organic photodetector is specifically carried out according to the following steps:

[0073] Step 1, first plate the ITO electrode layer 2 on the glass substrate 1, then use deionized water to ultrasonically clean the glass substrate 1 with the ITO electrode layer 2 for 17 minutes, and then use acetone to clean the glass substrate of the ITO electrode layer 2. 1. Perform ultrasonic cleaning for 17 minutes, and finally use absolute ethanol to ultrasonically clean the glass substrate 1 of the ITO electrode layer 2 for 17 minutes, and then dry it with pure nitrogen or infrared to obtain the glass substrate 1 coated with the ITO electrode layer 2;

[0074] Step 2, after the glass substrate 1 coated with the ITO electrode layer 2 is cleaned with ultraviolet ozone light, it is placed in a nitrogen glove box, and the PEDOT:PSS mixture is spin-coated on the surface of the ITO electrode layer 2 by a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com