Preparation method of organic photoelectric detector and prepared organic photoelectric detector

A photodetector, organic technology, applied in photovoltaic power generation, electric solid state device, semiconductor/solid state device manufacturing, etc., can solve the problem of device photoelectric responsivity and EQE reduction, photogenerated carriers cannot be effectively extracted, and reduce device ratio detection. rate and other issues, to achieve the effect of optimizing internal configuration, realizing dark current and light response performance, and ensuring quality stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

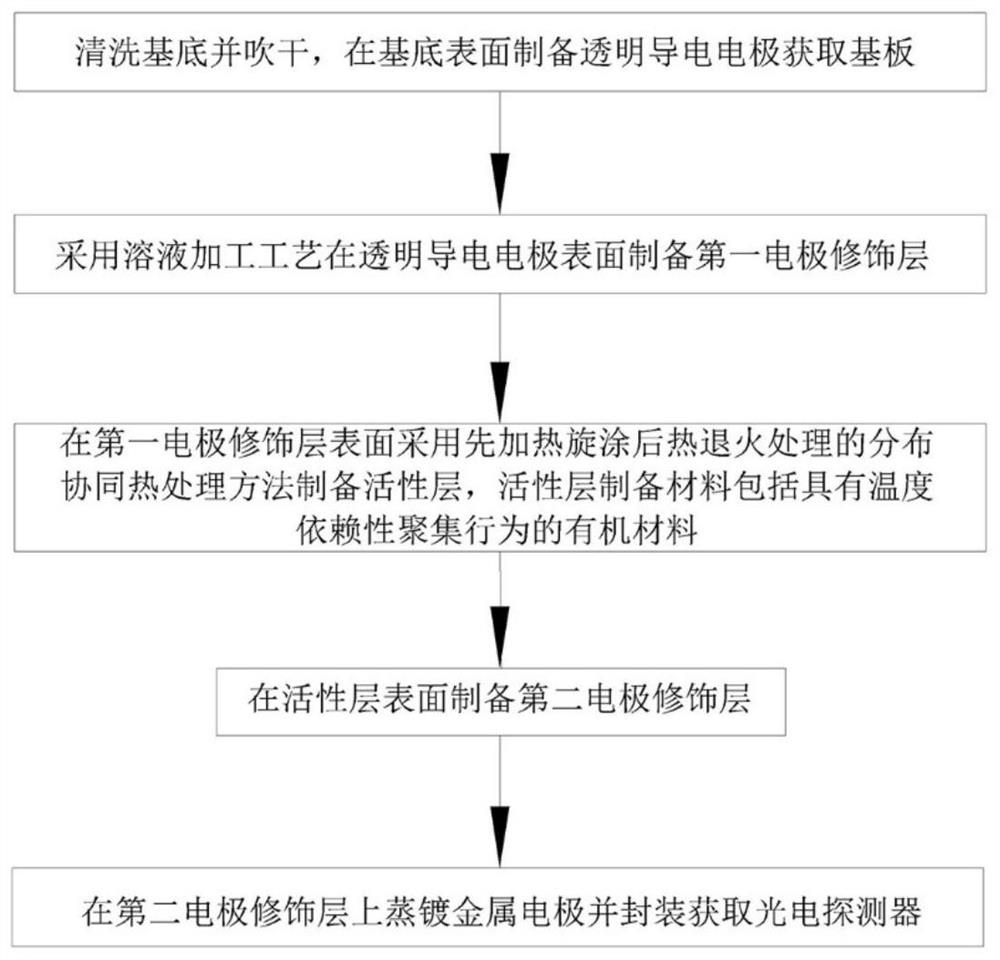

[0031] A method for preparing an organic photodetector, such as figure 1 shown, including

[0032] Clean the substrate and dry it, and prepare a transparent conductive electrode on the surface of the substrate to obtain the substrate;

[0033] preparing a first electrode modification layer on the surface of the transparent conductive electrode by using a solution processing technique;

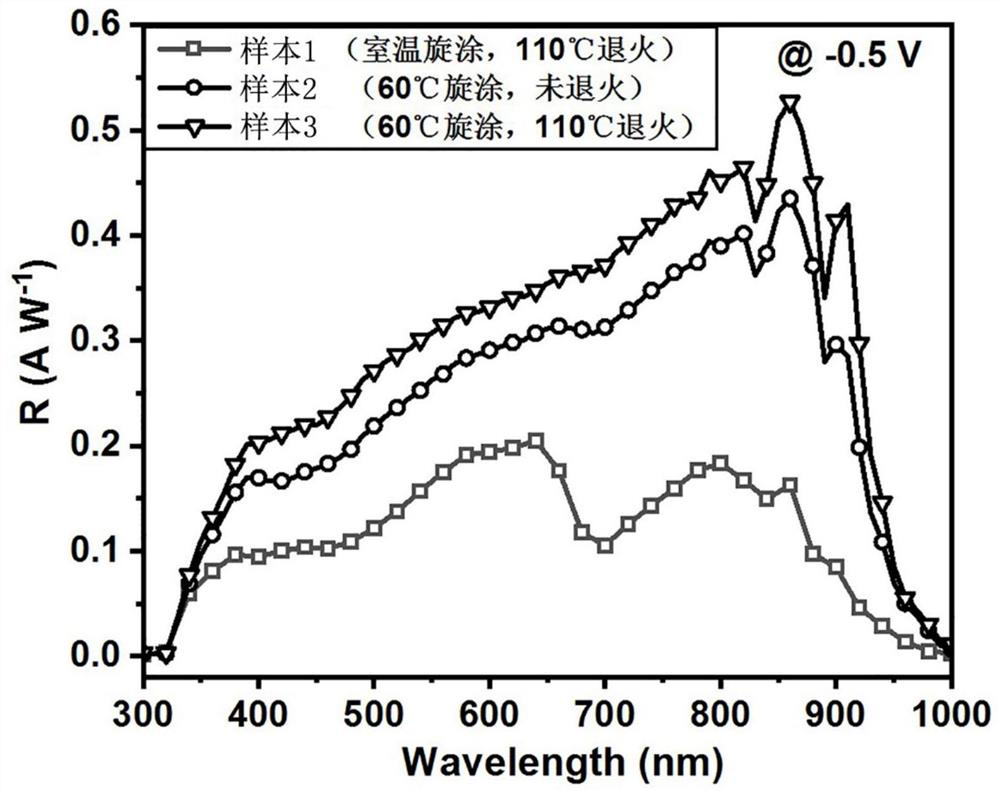

[0034] On the surface of the first electrode modification layer, the active layer is prepared by a distributed synergistic heat treatment method of first heating, spin coating and then thermal annealing, and the preparation material of the active layer includes an organic material with temperature-dependent aggregation behavior;

[0035] preparing a second electrode modification layer on the surface of the active layer;

[0036] A metal electrode is vapor-deposited on the second electrode modification layer, and a photodetector is obtained by packaging.

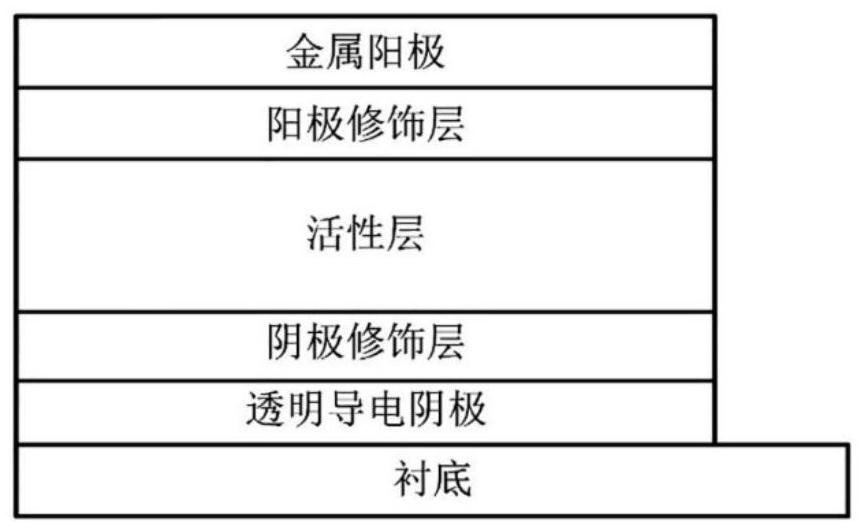

[0037] An organic photodetector prep...

Embodiment 1

[0040] A method for preparing an organic photodetector. The prepared organic photodetector adopts an inverse structure. The preparation method specifically includes the following steps:

[0041] S01, cleaning the substrate and drying it with nitrogen gas after cleaning.

[0042] S02. Prepare a transparent conductive cathode on the surface of the substrate by magnetron sputtering, thermal evaporation, electron beam evaporation, spin coating, screen printing, spray coating or scrape coating, and then clean it with ultraviolet ozone.

[0043] Wherein, the substrate is glass or a transparent flexible substrate, and the transparent conductive cathode is an ITO film or FTO film. In this embodiment, the transparent conductive cathode ITO is used as an example for illustration, and the substrate and the transparent conductive cathode together constitute an ITO conductive glass.

[0044] S03. Prepare a cathode modification layer on the surface of the transparent conductive cathode by o...

Embodiment 2

[0058] The difference between this embodiment and the first embodiment is that the prepared organic photodetector adopts a positive structure. The preparation method of organic photodetector comprises:

[0059] S01, cleaning the substrate and drying it with nitrogen gas after cleaning.

[0060] S02. Prepare a transparent conductive anode on the surface of the substrate by magnetron sputtering, thermal evaporation, electron beam evaporation, spin coating, screen printing, spray coating or scrape coating, and then clean it with ultraviolet ozone.

[0061] The transparent conductive anode is an ITO film or FTO film, and the substrate and the transparent conductive anode together form an ITO conductive glass.

[0062] S03. Prepare an anodic modification layer on the surface of the transparent conductive anode by using a solution processing technology of spin coating, screen printing, spray coating and scraping coating. The material of the anode modification layer is poly-TPD, PVK...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com