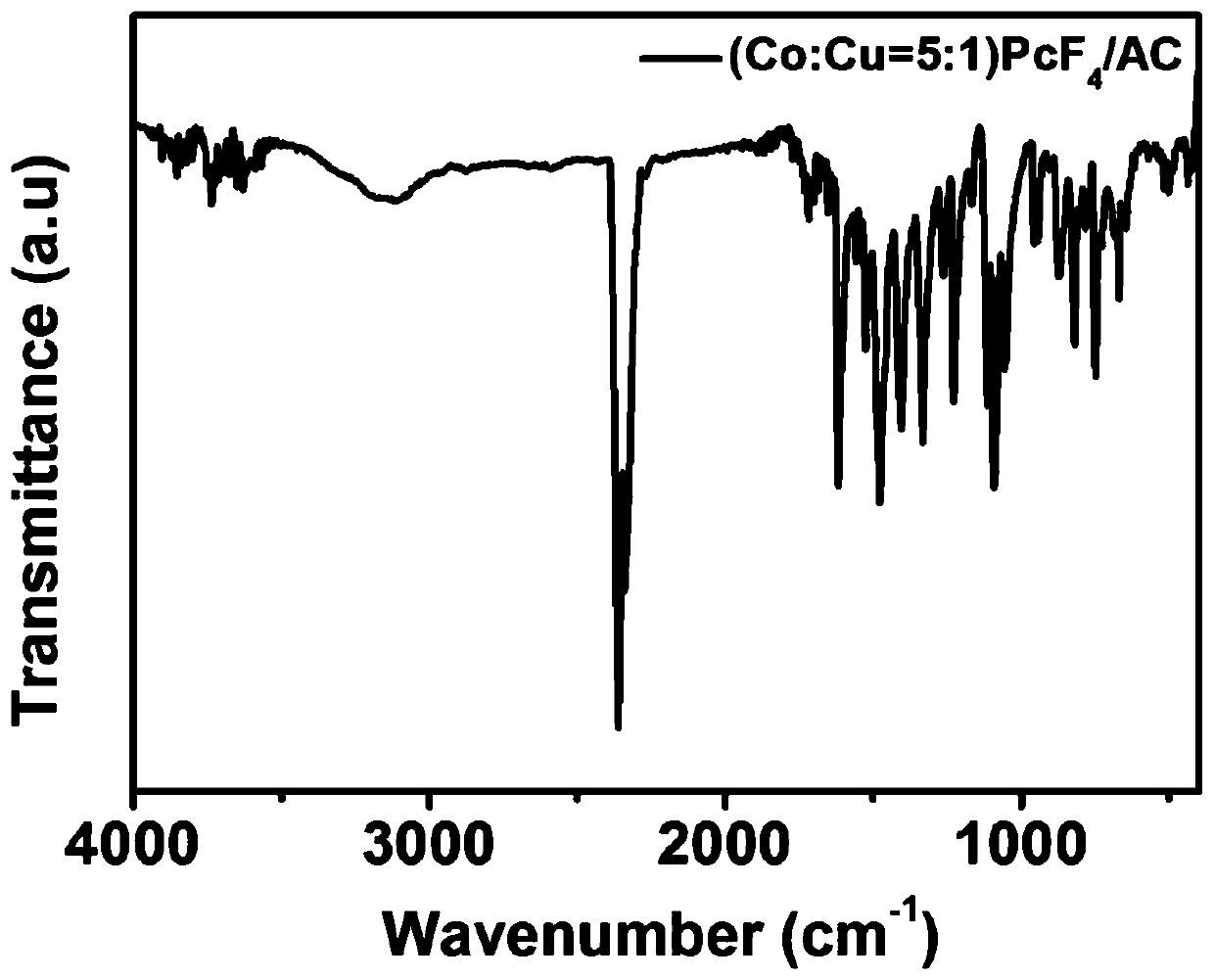

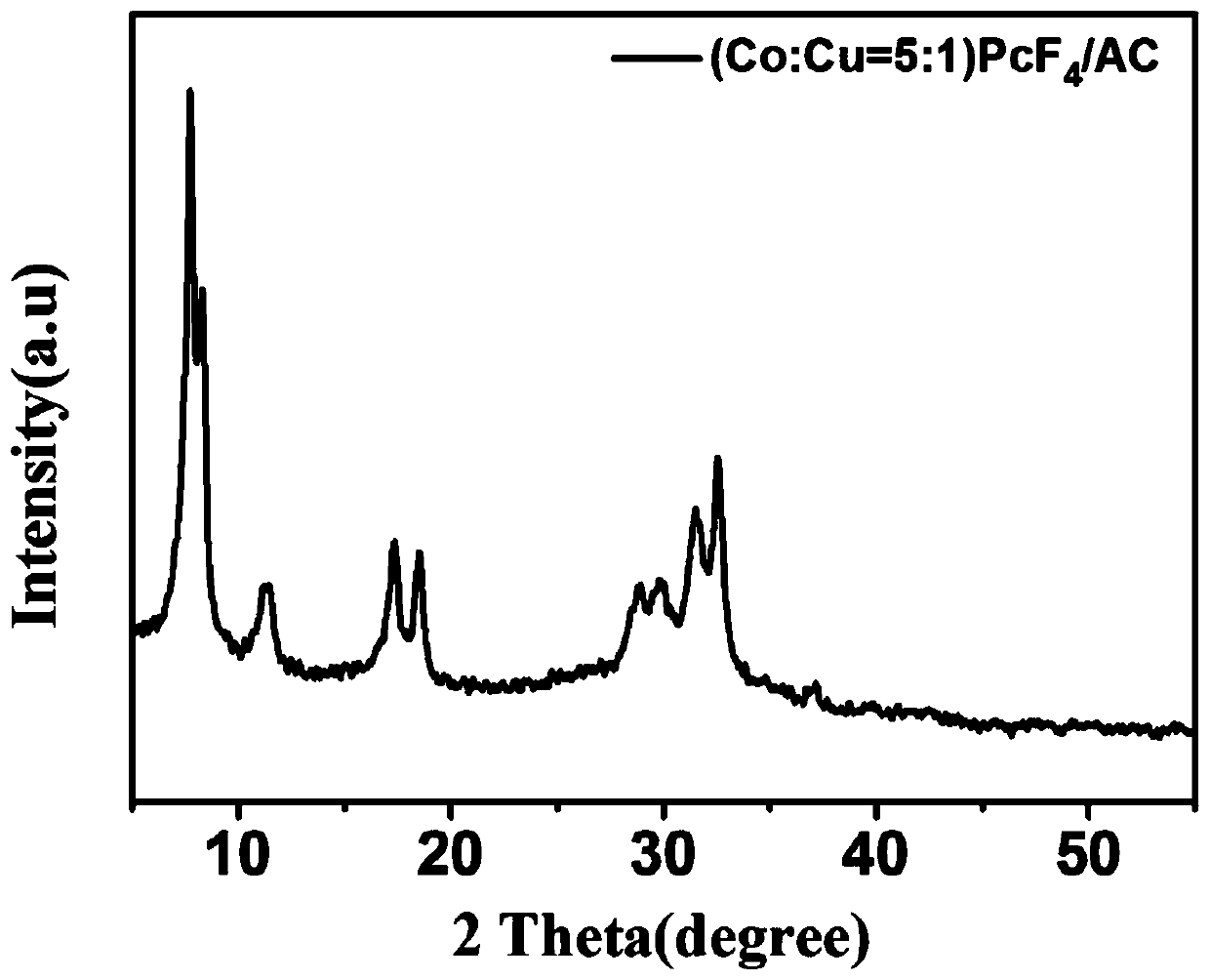

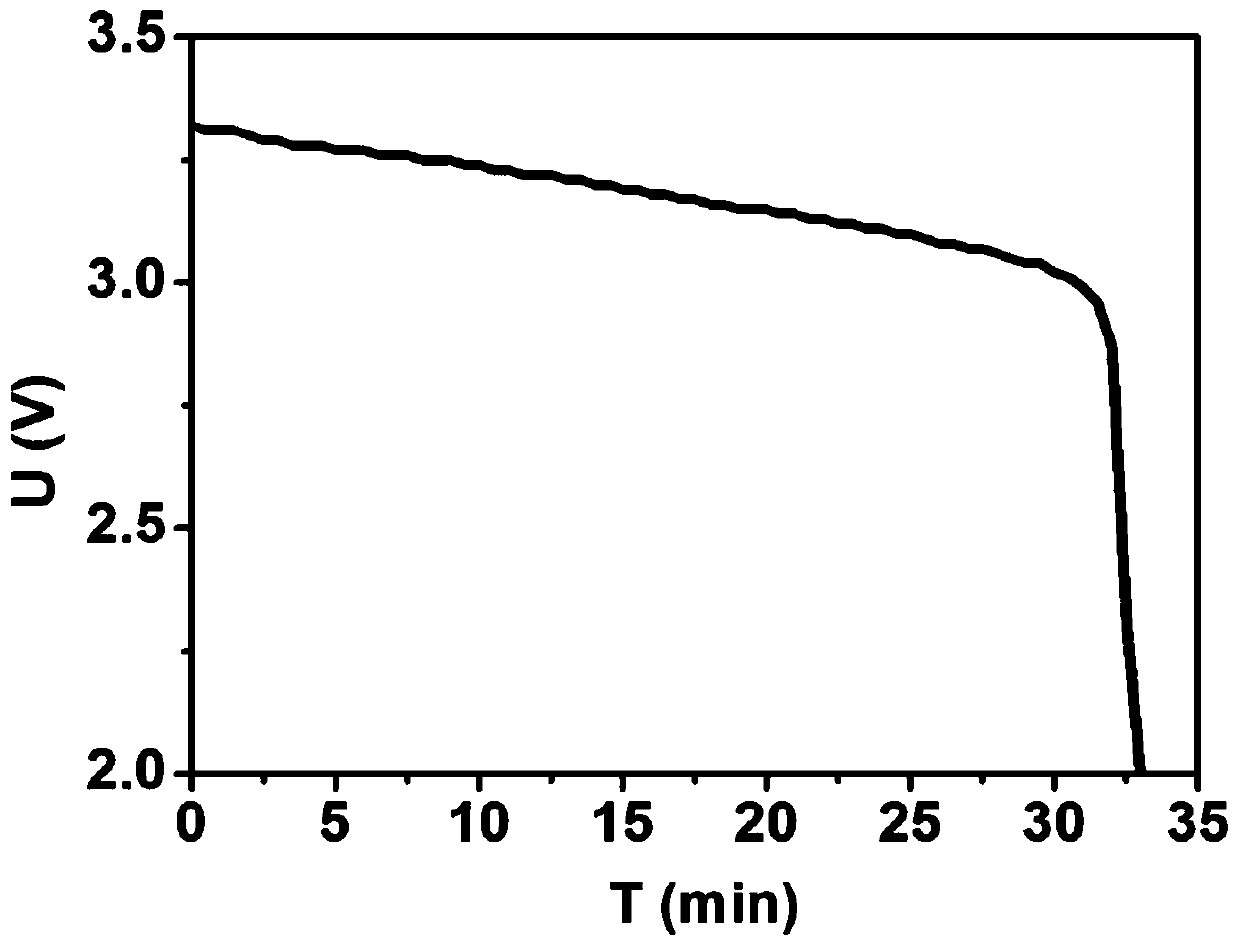

Mononuclear fluorine-substituted bimetal phthalocyanine complex/activated carbon lithium thionyl chloride battery catalytic material and preparation method thereof

A technology for lithium thionyl chloride batteries and catalytic materials, which is applied to battery electrodes, non-aqueous electrolyte batteries, circuits, etc., can solve the problems of small size, low cost and high purity, and achieves good uniformity, low cost and simple preparation method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1) Take 0.46g of 4-fluorophthalic anhydride and 0.06g of specific surface area of 1200m 2 / g of pitch coke activated carbon was mixed evenly in a glass mortar;

[0025] 2) Take 0.6g of urea, 0.08g of ammonium molybdate, 0.35g of cobalt chloride hexahydrate and 0.092g of copper chloride dihydrate and add them to the above-mentioned glass mortar and grind them thoroughly and put them into a crucible in a muffle furnace Sintering, muffle furnace at 10°C min -1 Heat up at a speed of 130°C from room temperature and keep warm for 0.2h; then at 5°C min -1 The temperature was raised to 240°C at a certain speed, and the temperature was kept for 2 hours;

[0026] 3) Naturally cool to room temperature, wash the prepared product with ultrapure water for 10 hours, change the water and wash 8 times, then use water and ethanol to filter, wash several times, and dry to obtain the mononuclear fluorine-substituted bimetallic phthalocyanine complex / Activated carbon lithium thionyl c...

Embodiment 2

[0028] 1) Take 0.819g of 4-fluorophthalic anhydride and 0.1g of specific surface area of 1200m 2 / g of pitch coke activated carbon was mixed evenly in a glass mortar;

[0029] 2) Take 0.6g of urea, 0.08g of ammonium molybdate, 0.2g of cobalt chloride hexahydrate and 0.1g of copper chloride dihydrate and add them to the above-mentioned glass mortar and grind them thoroughly, then put them into a crucible in a muffle furnace Sintering, muffle furnace at 10°C min -1 The temperature is raised at a speed of 140°C from room temperature, and kept for 0.5h; then at 5°C min -1 The temperature is raised to 250°C at a certain speed, and the temperature is kept for 1.5h;

[0030] 3) Naturally cool to room temperature, wash the obtained product with ultrapure water for 24 hours, change the water and wash 8 times, then use water and ethanol to filter, wash several times, and dry to obtain the mononuclear fluorine-substituted bimetallic phthalocyanine complex / Activated carbon lithium t...

Embodiment 3

[0032] 1) Take 0.92g of 4-fluorophthalic anhydride and 0.1g of specific surface area of 1200m 2 / g of pitch coke activated carbon was mixed evenly in a glass mortar;

[0033] 2) Take 1.2g of urea, 0.12g of ammonium molybdate, 0.458g of cobalt chloride hexahydrate and 0.06g of copper chloride dihydrate and add them to the above-mentioned glass mortar and grind them thoroughly and put them into a crucible in a muffle furnace Sintering, muffle furnace at 10°C min -1 The temperature is raised at a speed of 150°C from room temperature, and kept for 0.5h; then at 5°C min -1 The temperature is raised to 270°C at a certain speed, and the temperature is kept for 2 hours;

[0034] 3) Naturally cool to room temperature, wash the obtained product with ultrapure water for 24 hours, change the water and wash 9 times, then use water and ethanol to filter, wash several times, and dry to obtain the mononuclear fluorine-substituted bimetallic phthalocyanine complex / Activated carbon lithiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com