Metal-organic framework compound derived metal sulfide nanosheet and preparation method thereof

A metal-organic framework, metal sulfide technology, applied in the direction of cobalt compounds, nickel sulfide, inorganic chemistry, etc., can solve the problems of low-cost, large-scale, controllable preparation, etc., to achieve a wide range of options, good application prospects, reaction Highly active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

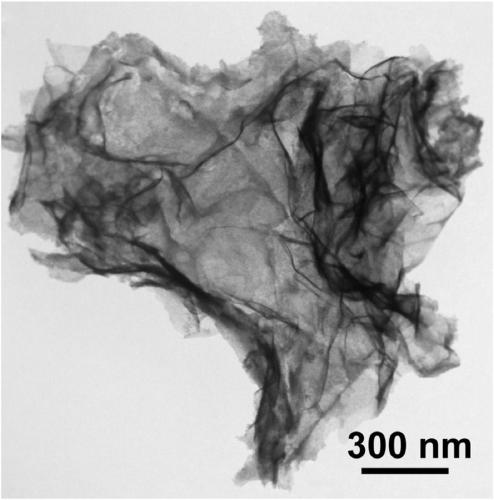

[0031] Will contain 0.58g Co(NO 3 ) 2 ·6H 2 A 40 mL solution of O was poured into a 40 mL solution containing 1.31 g of 2-methylimidazole, then magnetically stirred for 1 h, centrifuged at 6500 rpm for 5 min, and washed 4 times with water, then the sediment was redispersed in 140 mL of deionized water, and poured into 40 mL of sulfur Acetamide (1.2g) aqueous solution was stirred at 100°C for 2h, centrifuged at 9000rpm for 5min, washed 4 times with water, redispersed in 200mL of water, and freeze-dried to obtain wrinkled cobalt sulfide (CoS 2 ) nanosheets, such as figure 1 shown.

Embodiment 2

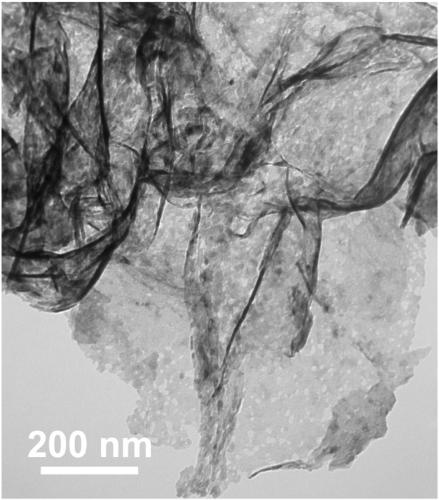

[0033] Will contain 0.29g Co(NO 3 ) 2 ·6H 2 40 mL solution of O was poured into 40 mL solution containing 0.655 g 2-methylimidazole, then magnetically stirred for 4 h, centrifuged at 6500 rpm for 5 min, and washed 4 times with water, then the sediment was redispersed in 140 mL deionized water, and poured into 40 mL sulfur Acetamide (1g) aqueous solution was stirred at 85°C for 2h, centrifuged at 6500rpm for 5min, washed 4 times with water, redispersed in a certain amount of deionized water, freeze-dried to obtain wrinkled sulfide nanosheets, under nitrogen protection, The obtained sulfide nanosheets were heat-treated at 450 °C for 2 h to obtain porous cobalt sulfide (Co 3 S 4 ) nanosheets, such as figure 2 shown.

Embodiment 3

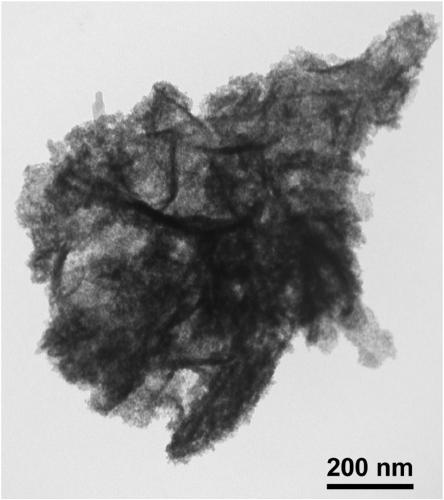

[0035] Will contain 0.29g Zn(NO 3 ) 2 ·6H 2 O and 0.29g Co(NO 3 ) 2 ·6H 2 40mL solution of O was poured into 40mL solution containing 1.31g 2-methylimidazole, then magnetically stirred for 24h, centrifuged at 6500rpm for 5min, and washed 4 times with water, then the sediment was redispersed in 140mL deionized water, and poured into 40mL sulfur Acetamide (1.2g) aqueous solution was stirred at 50°C for 5h, centrifuged at 6500rpm for 5min, washed 4 times with water, redispersed in a certain amount of deionized water, and freeze-dried to obtain zinc-cobalt bimetallic sulfide (ZnCoS 2 ) nanosheets, such as image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com