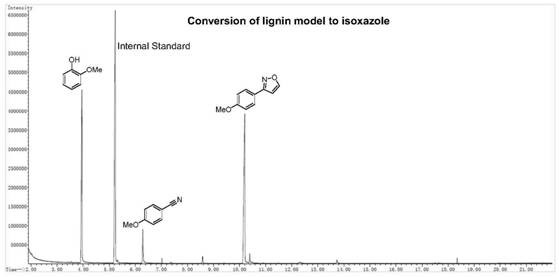

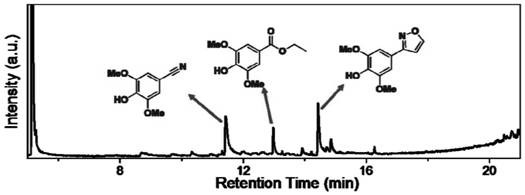

A method of converting lignin to isoxazoles and aromatic nitriles

A technology of lignin and isoxazole, which is applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., to achieve the effects of simple conversion method, expanded application prospect, and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

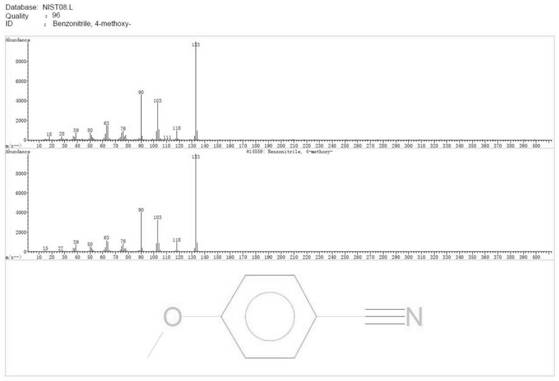

Embodiment 1

[0036] In a 15mL pressure bottle, add 1mL methanol, 0.1mmol 3-hydroxy-2-(2-methoxyphenoxy)-1-(4-methoxyphenyl)propyl-1-one and 0.3mmol hydrochloric acid Hydroxylamine was filled with nitrogen to replace the atmosphere, sealed, and the reaction was stirred at 120 ° C for 12 h. After the reaction was completed, centrifugation was performed, and the product was detected by chromatography. The conversion rate and yield are shown in Table 1.

Embodiment 2

[0038] In a 15mL pressure bottle, add 1mL methanol, 0.1mmol 3-hydroxy-2-(2-methoxyphenoxy)-1-(4-methoxyphenyl)propyl-1-one, 0.3mmol hydrochloric acid Hydroxylamine and 0.2 mmol MgO were filled with nitrogen to replace the atmosphere, sealed, and the reaction was stirred at 120 ° C for 12 h. After the reaction was completed, centrifugation was performed, and the product was detected by chromatography. The conversion rate and yield are shown in Table 1.

Embodiment 3

[0040] In a 15mL pressure bottle, add 1mL methanol, 0.1mmol 3-hydroxy-2-(2-methoxyphenoxy)-1-(4-methoxyphenyl)propyl-1-one, 0.3mmol hydrochloric acid Hydroxylamine and 0.2 mmol ZnO were filled with nitrogen replacement atmosphere, sealed, and stirred at 120 ° C for 12 h. After the reaction was completed, centrifugation was performed, and the product was detected by chromatography. The conversion rate and yield are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com