Super-soft X/gamma ray protective material and preparation method thereof

A protective material and γ-ray technology, applied in radiation-absorbing coatings, filling pastes, shielding, etc., can solve the problems of easy hardening, moisture absorption, and swelling of finished products, etc., to achieve tensile strength and tear resistance Improvement of cracking performance, increase of anti-aging performance, and enhancement of anti-aging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

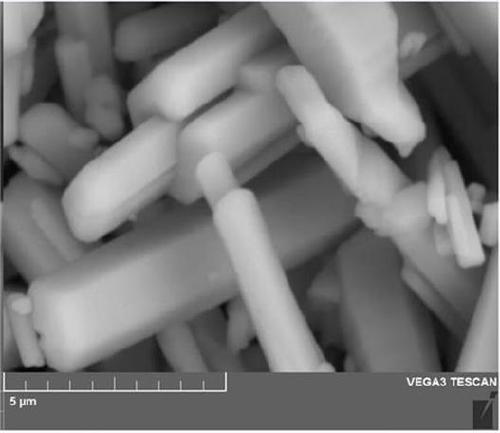

[0050] An ultra-soft X / γ-ray protective material, consisting of the following components: 89wt% crystallized X / γ-ray absorbing functional body, 9wt% CPE, 2wt% additives: epoxy soybean oil, stearic acid, Anti-aging agent; the median particle size D50 of the crystallized X / γ-ray-absorbing functional body is greater than 10 μm, and the ratio of crystallized raw materials is specifically shown in Table 1; the acquisition method of the crystallized X / γ-ray-absorbing functional body is Sintering: The super-soft X / γ-ray protection material is a diaphragm material with a thickness of 0.4 mm formed by calendering.

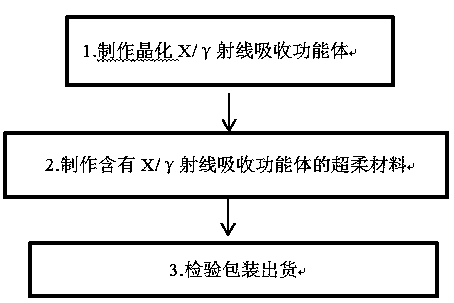

[0051] Refer to the process flow figure 1 , the relevant ingredients and production steps are as follows:

[0052] Step 1. Making crystallized X / γ-ray absorbing functional body

[0053] Table 1 The composition of the raw materials of the crystallized X / γ-ray absorbing functional body:

[0054]

[0055] The production steps are as follows:

[0056] Mixing: According t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com