Perovskite photoelectric detector with optical micro cavity structure and preparation method thereof

A photoelectric detector and optical microcavity technology, which is applied in the field of visible light detection, can solve the problems of poor detection performance and wide half-wave peak of the detector, and achieve the effect of novel and unique structure, narrow detection half-wave peak width, and improve device performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

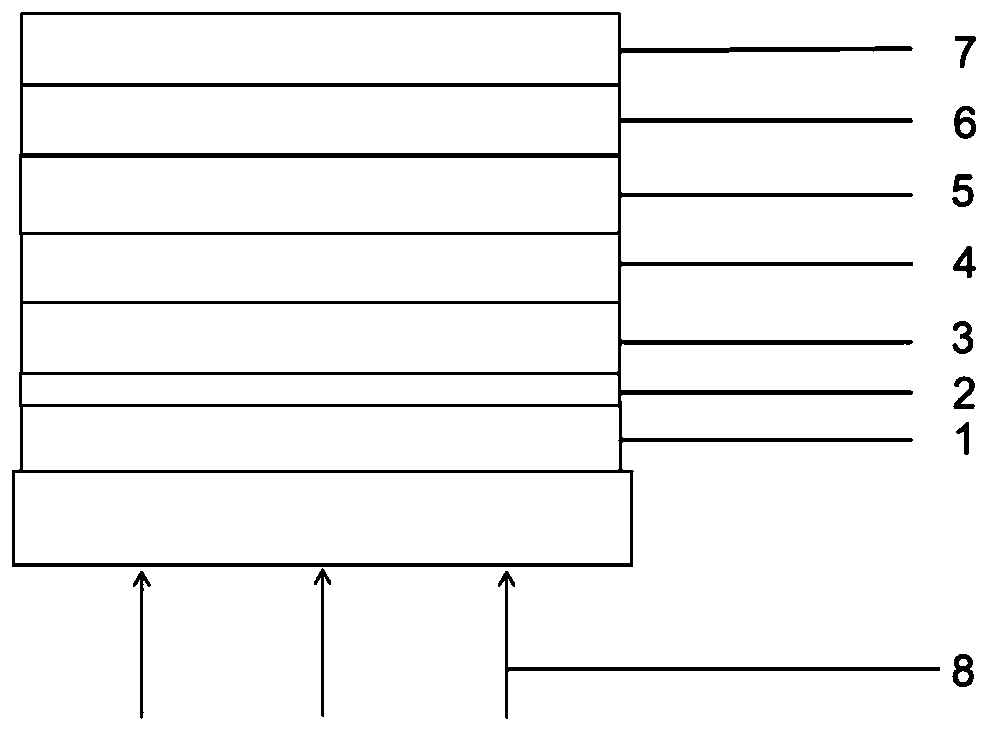

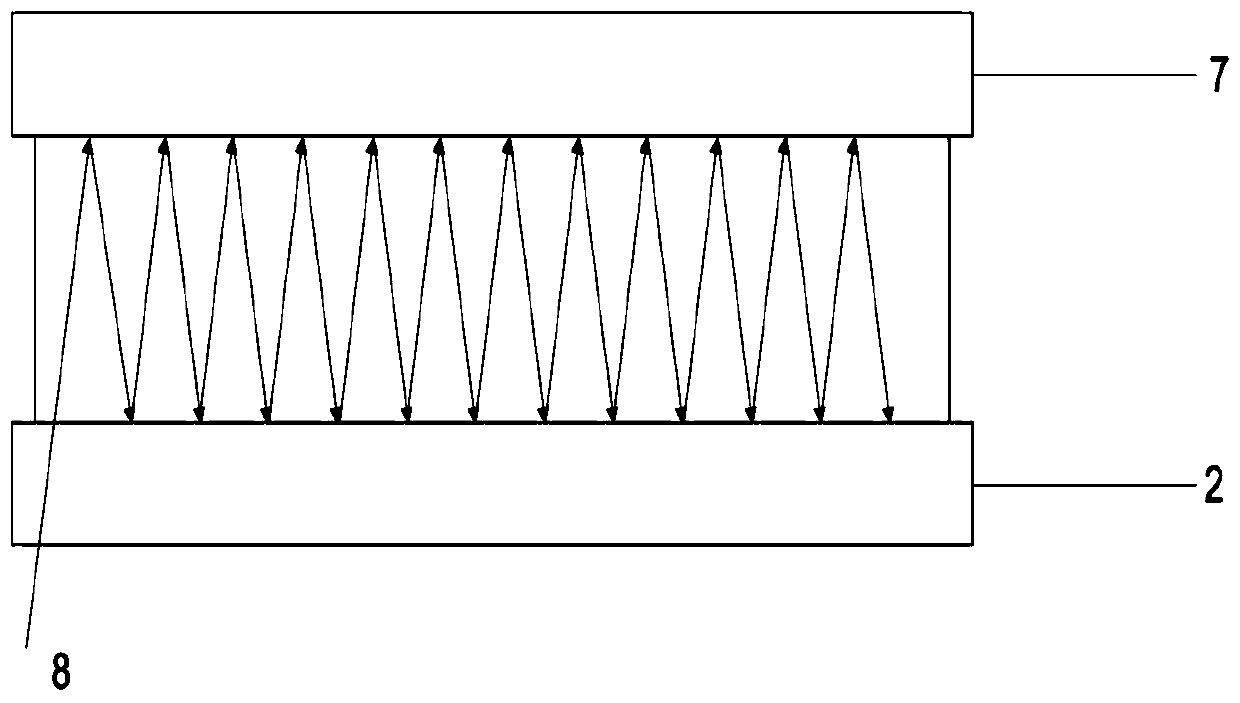

[0040] A perovskite photodetector with an optical microcavity structure based on the charge-narrowing absorption effect, such as figure 1 As shown, including bottom-up glass substrate, transparent conductive electrode layer 1, light reflection layer 2, hole transport layer 3, perovskite sensitive layer 4, electron transport layer 5, hole blocking layer 6 and metal electrode layer 7. Among them, the transparent conductive electrode layer 1 adopts an ITO transparent conductive electrode with a thickness of 150nm, the light reflection layer 2 adopts silver with a thickness of 5nm, and the hole transport layer 3 adopts PEDOT:PSS film, CuSCN, CuI, NiO with a thickness of 90nm. x In any one, the perovskite sensitive layer 4 adopts CH with a thickness of 500nm 3 NH 3 PB 2 Br film, the electron transport layer 5 adopts PC with a thickness of 80nm 61 BM film, TiO 2 And any one of ZnO, the hole transport layer 3 adopts C with a thickness of 80nm 60 Thin film, ZnO, BCP and Al 2 o ...

Embodiment 2

[0053] On the basis of Example 1, methylamine lead bromine was dissolved in DMF (N-N dimethylformamide) solution, and after stirring for 6 hours at 100°C, a perovskite precursor solution was obtained; the light reflection layer was 2nm thick Gold; the thickness of the perovskite sensitive layer 4 is 50nm;

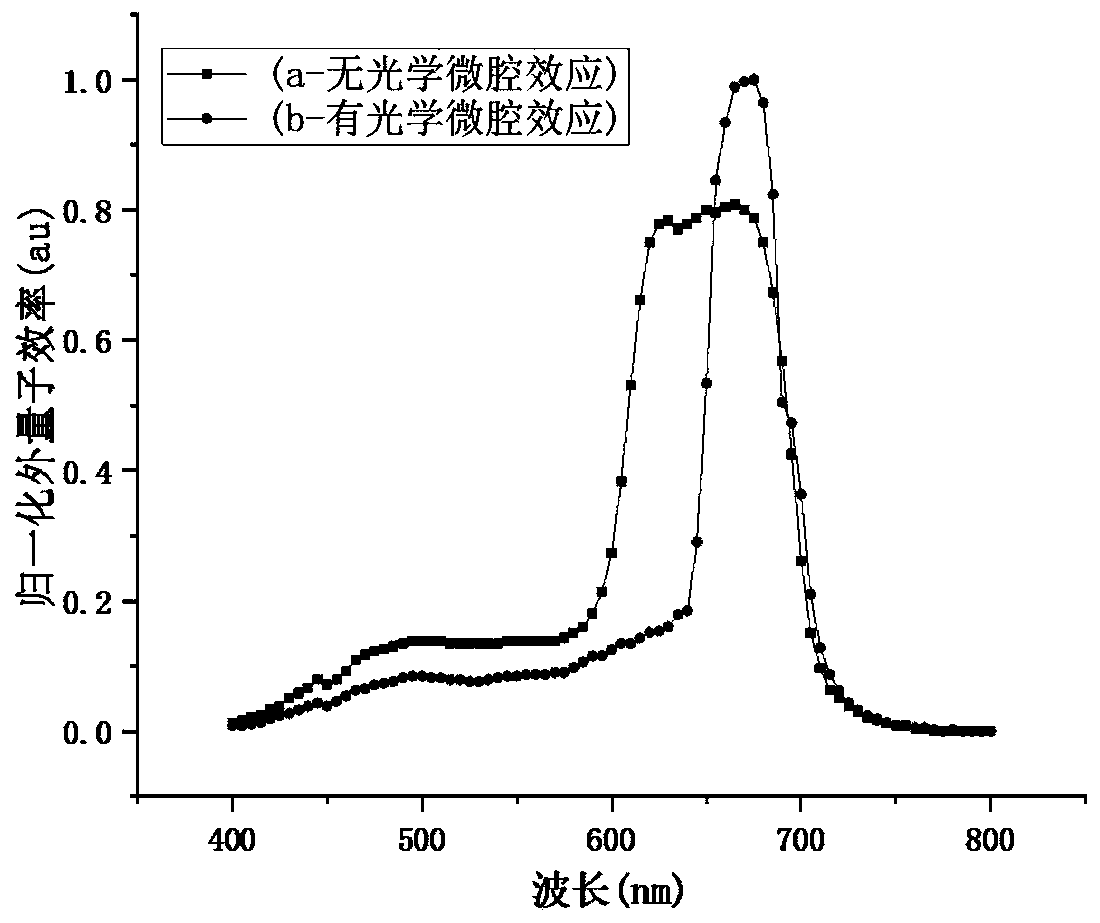

[0054] Under standard test conditions, a light beam is extracted from a visible light source, so that the incident light 8 is vertically incident on the perovskite photodetector. The test results show that the perovskite visible light detector responds to the 525-575nm band, and its half-wave peak width is 40nm at the peak of 550nm, and its detection rate is ~10 12 Jones.

Embodiment 3

[0056] On the basis of Example 1, methylamine lead iodide and methylamine lead bromine are dissolved in DMF (N-N dimethylformamide) solution according to the molar ratio of 1.4:0.6, and doped with PEIE of 0.33% mass ratio, in After stirring at 100° C. for 6 hours, a perovskite precursor solution was obtained; the light reflection layer was made of aluminum with a thickness of 10 nm; the thickness of the perovskite sensitive layer 4 was 5000 nm;

[0057] Under standard test conditions, a light beam is extracted from a visible light source, so that the incident light 8 is vertically incident on the perovskite photodetector. The test results show that the perovskite visible light detector responds to the 400-500nm band, and its half-wave peak width is 50nm at the peak of 450nm, and its detection rate is ~10 12 Jones.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com