Preparation method and application of primordial water hyacinth biomass carbon porous electrode material

A porous electrode and biomass carbon technology, applied in chemical instruments and methods, water pollutants, carbon compounds, etc., can solve problems such as water hyacinth invasive species, achieve rich oxygen reduction reaction active sites, and high electron transfer efficiency , the effect of excellent catalytic degradation activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

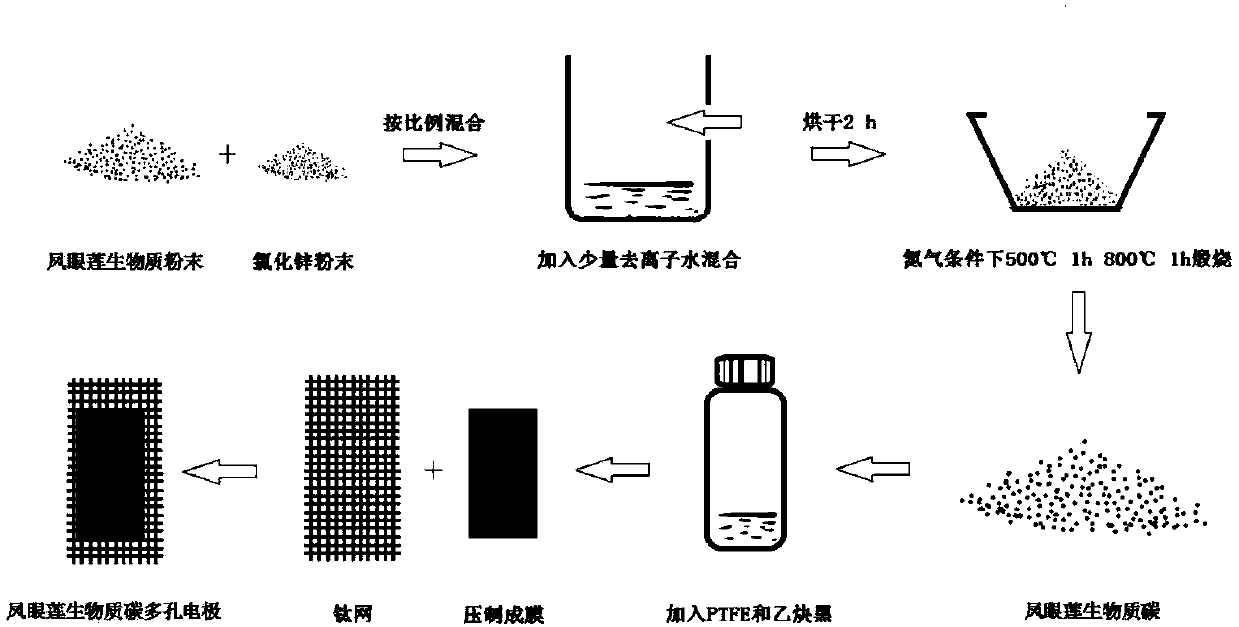

[0039] Preparation of water hyacinth biomass carbon porous electrode, the steps are as follows:

[0040] (1) Pretreatment of precursors:

[0041] After the roots of the water hyacinth plant were removed and discarded, the surface impurities of the stems and leaves were washed with deionized water, and then put into an oven for dehydration at 100° C. for 48 hours. The dried water hyacinth biomass is crushed into powder using a pulverizer. The biomass passed through a 100-mesh sieve was put into a sample bag and stored in a dry place away from light for future use.

[0042] (2) Activated carbonization of precursors:

[0043] Weigh three parts of 3.0g biomass powder and put them into 50mL beakers respectively, add zinc chloride (ZnCl 2 ) powder 0g, 3.0g and 6.0g, 9.0g and 12.0g, then add 25mL deionized water respectively, stir for 30min and mix well. The mixture was poured into a Petri dish, put in an oven for 2 h, and the solution was evaporated to dryness. Scrape the dried...

Embodiment 2

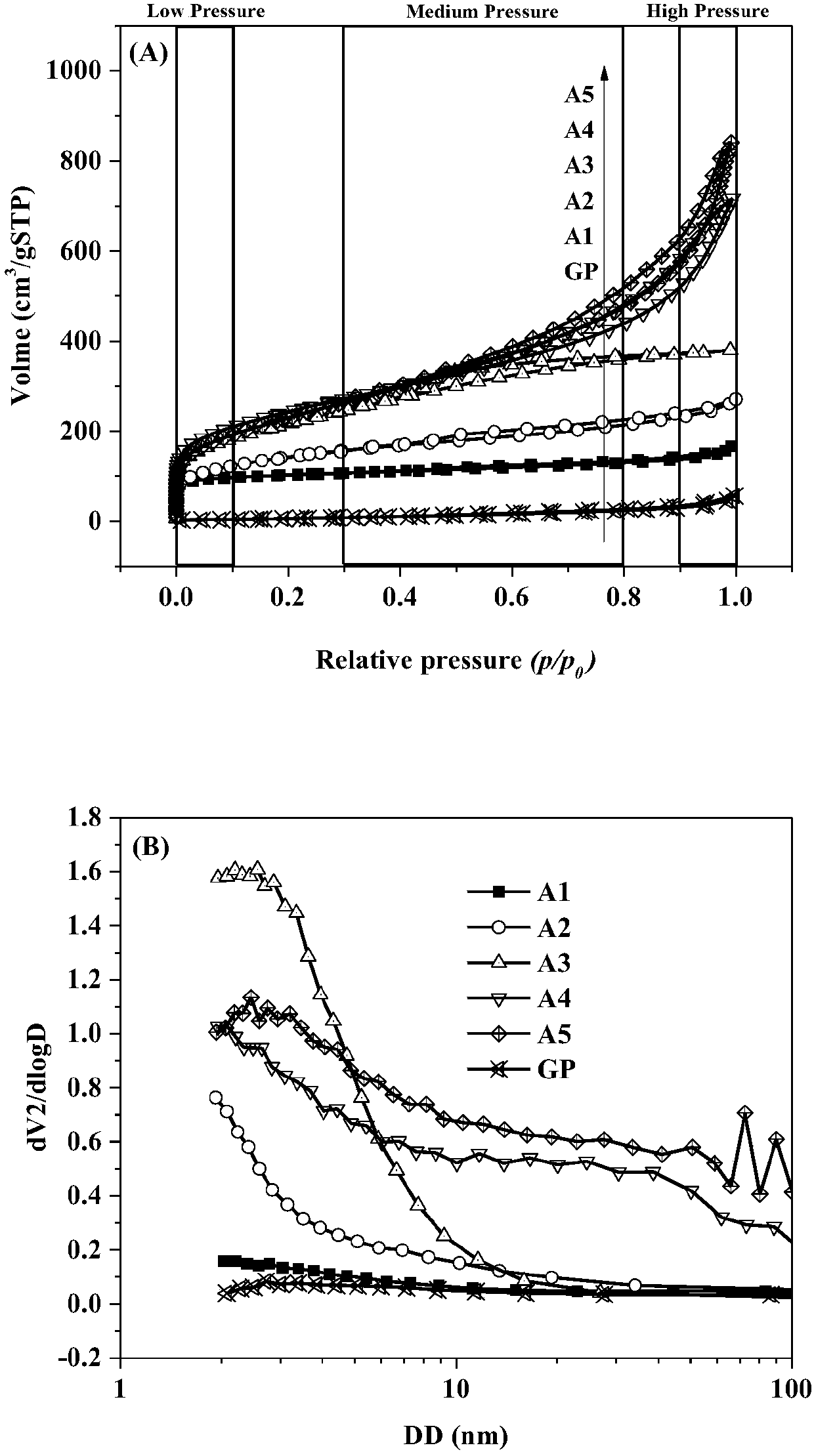

[0046] Example 2: Specific surface area, pore volume and pore size distribution test of water hyacinth biomass carbon material

[0047] The results of the specific surface area, pore volume and pore diameter of water hyacinth hydrangea biomass carbon before and after activation with zinc chloride are shown in Table 1:

[0048] Table 1

[0049]

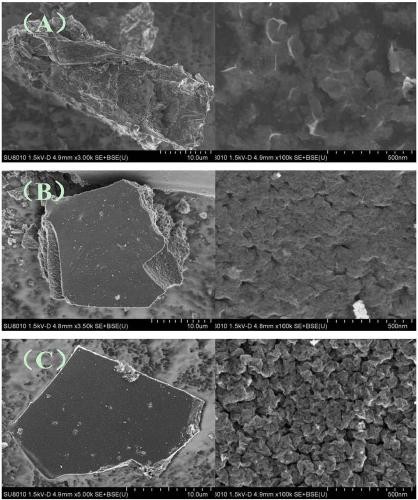

[0050] S from Table 1 BET The data shows that with the increase of the proportion of the activator, the specific surface area and total pore volume of the water hyacinth biomass carbon material obtained after activation are larger; the maximum value is 845.184m3 of the specific surface area of A4 2 / g, the corresponding pore volume is 1.108cm 3 / g. However, the specific surface area and micropore volume of A5 showed a downward trend. However, the total pore volume still increased to 1.300 cm 3 / g, which indicates that excessive activation will lead to the expansion of the pores, and the microporous structure will be transform...

Embodiment 3

[0055] Embodiment 3: Hydrogen peroxide production capacity test of the hyacinth hyacinth biomass carbon porous electrode prepared in embodiment 1

[0056] 1. Construction of three-electrode system

[0057] The water hyacinth biomass carbon porous electrode (3cm × 2cm) prepared in Example 1 is used as the cathode, the platinum electrode (Shanghai Russell Technology Co., Ltd., 213 type) is used as the anode, and the reference electrode is a saturated calomel electrode to form a three-electrode system together Applied to the measurement of E-Fenton hydrogen peroxide production.

[0058] 2. Preparation of titanium reagent

[0059] Take 272mL of 98wt% concentrated sulfuric acid and pour it into 300mL of distilled water. After the solution is cooled to room temperature, add 35.4g of potassium titanium oxalate dihydrate [K 2 TiO(C 2 o 4 ) 2 2H 2 O], and finally transferred to a 1L volumetric flask, added distilled water to constant volume and shaken well before use.

[0060] 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com