Preparation method of hypromellose specially used for plant capsules

A technology of hypromellose and plant capsules, which is applied in capsule delivery, medical preparations of non-active ingredients, pharmaceutical formulas, etc., and can solve the problems that the production process of plant capsules cannot be continuous, and the design performance of the production line cannot fully adapt to the production process, etc. , to achieve uniform distribution of replacement positions, ensure continuous production, and controllable viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

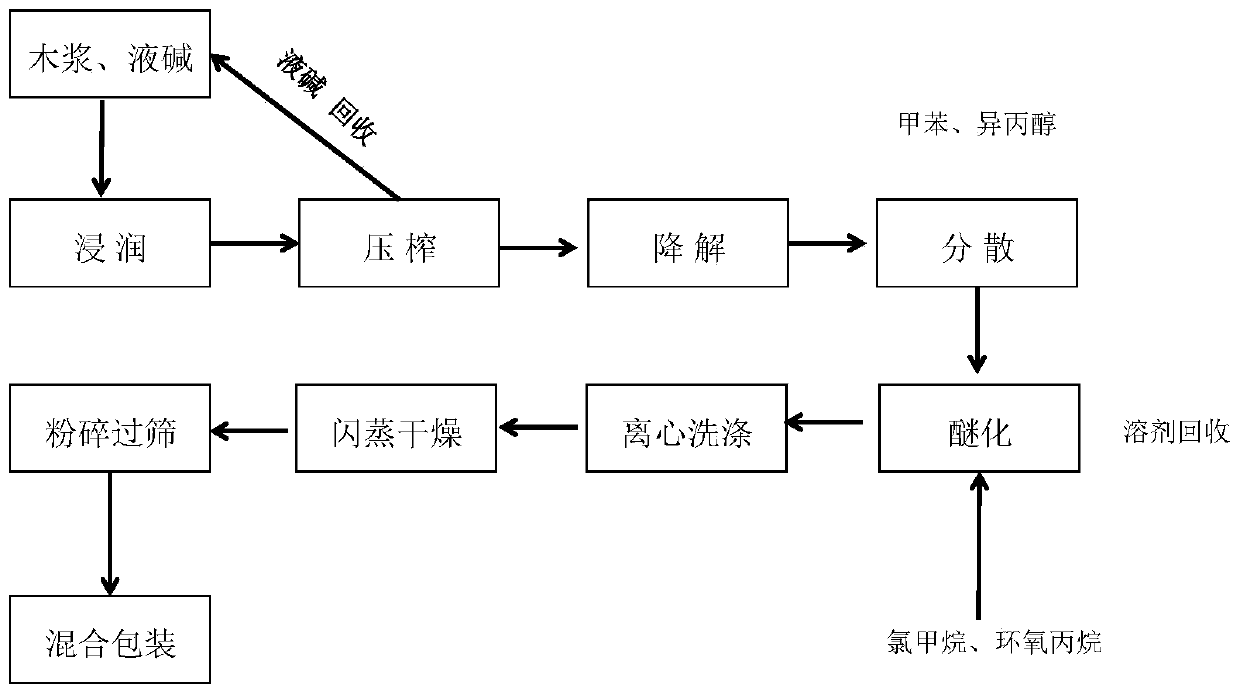

Method used

Image

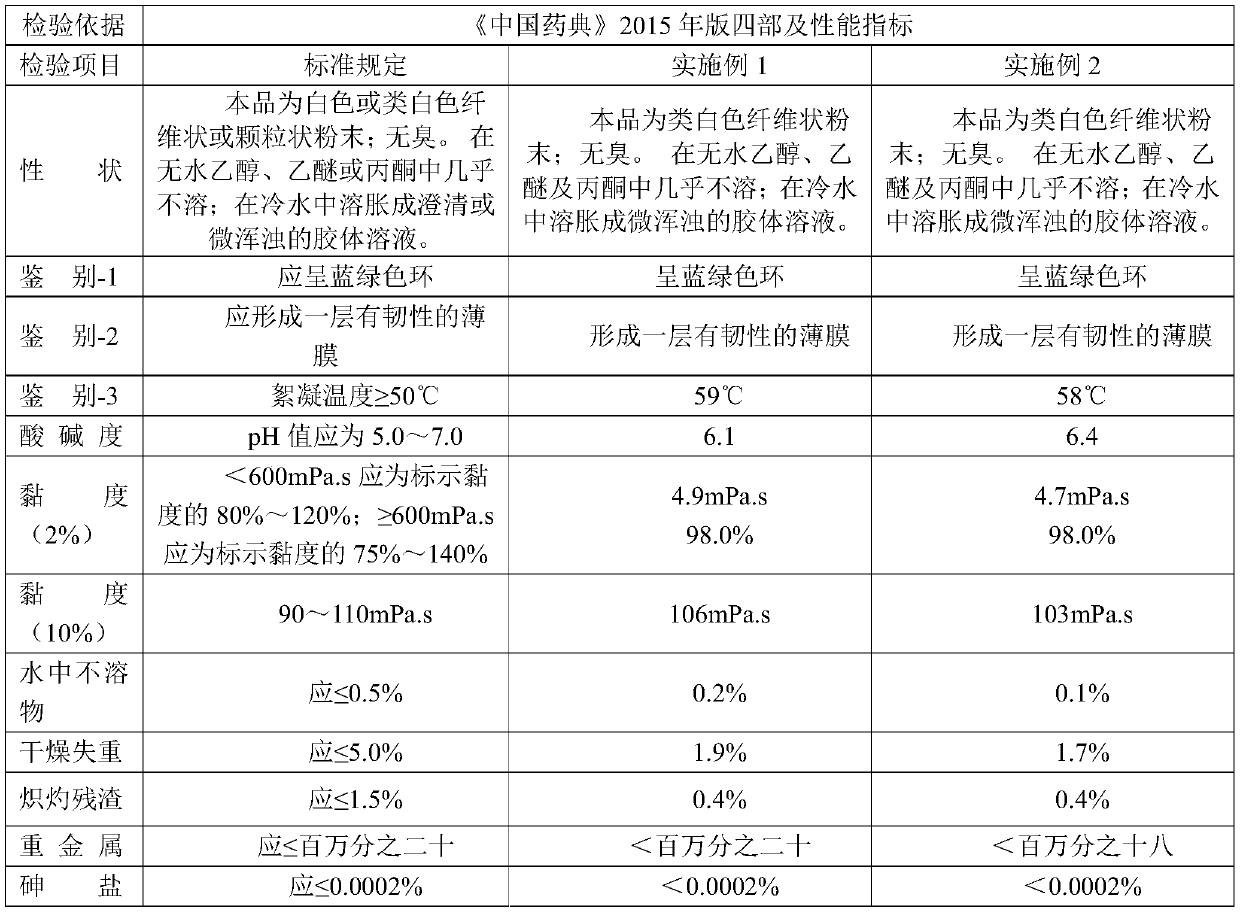

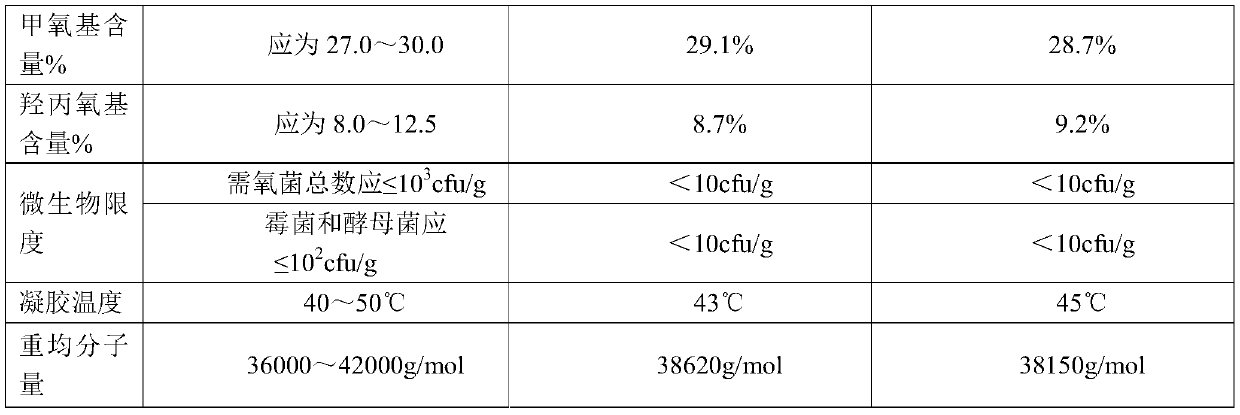

Examples

Embodiment 1

[0026] A preparation method of special hypromellose for plant capsules, comprising the following steps:

[0027] S1. Alkali soaking of wood pulp board: add 1000kg of 50% sodium hydroxide solution in the alkali soaking tank. Fully soak the cut 200kg wood pulp board in the alkali soaking tank;

[0028] S2, pressing: squeeze the soaked pulp board, control the pressing pressure, the mass ratio of wood pulp pulp board to lye is 1:1.1, and roll the soaked pulp board into rolls for later use with a rewinder;

[0029] S3. Degradation: put the pressed pulp board into a drying room with a temperature of 50°C and a relative humidity of 60% for oxidative degradation for 24 hours;

[0030] S4. Dispersion: pump 800kg of toluene and 200kg of isopropanol into the batching tank, and at the same time control the solvent moisture requirement below 5%; put the degraded material into the reactor, stir for 30 minutes, and disperse the material in the solvent;

[0031] S5. Etherification reaction:...

Embodiment 2

[0035] A preparation method of special hypromellose for plant capsules, comprising the following steps:

[0036] S1, wood pulp board soaking in alkali: add 400kg of 50% sodium hydroxide solution in the alkali soaking tank. Fully soak the cut 100kg wood pulp board in the alkali soaking tank;

[0037] S2, pressing: squeeze the soaked pulp board, control the pressing pressure, the mass ratio of the wood pulp pulp board to the lye is 1:0.8, and roll the soaked pulp board into rolls for later use with a rewinder;

[0038] S3. Degradation: put the pressed pulp board into a drying room with a temperature of 65°C and a relative humidity of 50% for oxidative degradation for 24 hours;

[0039] S4. Dispersion: pump 850kg of toluene and 150kg of isopropanol into the batching tank, and at the same time control the solvent moisture to be less than 5%; put the degraded material into the reactor and stir for 30 minutes to disperse the material in the solvent;

[0040] S5. Etherification rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com