One-component ink and water-based ink coating for 3c glass

A one-component, ink technology, applied in the field of ink, can solve the problems of affecting the health of employees, large VOC emissions, troublesome oil adjustment process, etc., to achieve excellent resistance to ultraviolet light aging, environmental protection, and improvement of the construction environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the above-mentioned one-component ink for 3C glass: while stirring, add organic-inorganic composite water-based resin, closed-type water-based curing agent, water, pigment, filler, and additives in sequence at a stirring speed of 800 rpm to 1500 rpm After mixing evenly, disperse at a speed of 2000 to 3000 rpm for 15 to 30 minutes, and grind on a sand mill until the particle size is less than 5 μm to obtain a one-component ink for 3C glass.

[0033] According to another aspect of the present invention, there is also provided a method for preparing a water-based ink coating, which includes the following steps: screen-print the above-mentioned one-component ink for 3C glass on a 3C glass substrate, and heat it at 150° C. Bake at ~180°C and cure to obtain a water-based ink coating. The preparation method of the water-based ink coating of the present invention is simple to operate. After printing on the 3C glass substrate, the water-based ink coatin...

Embodiment 1

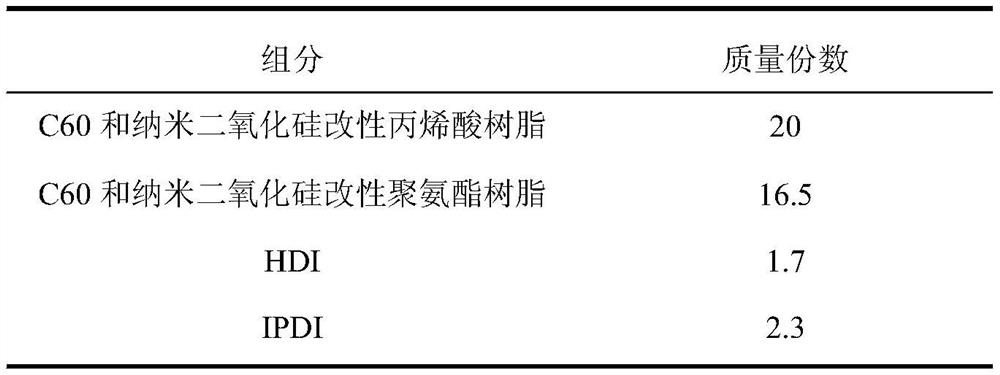

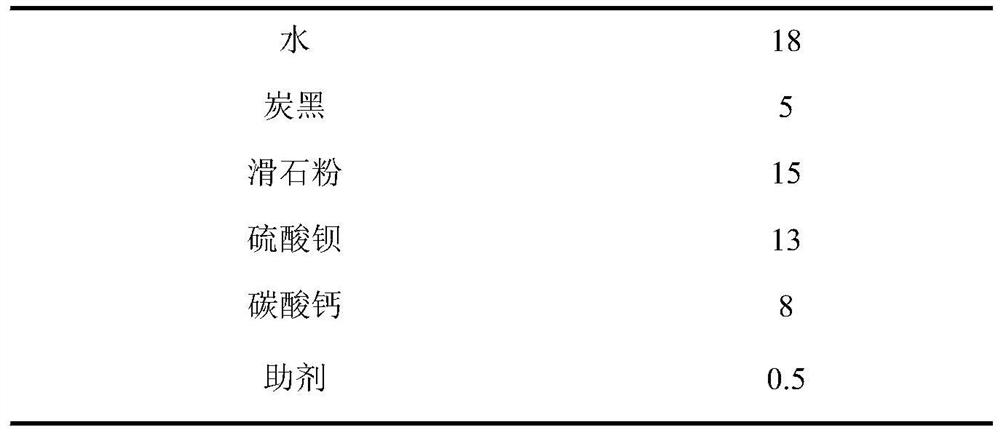

[0042] A preferred embodiment of the present invention provides a one-component ink for 3C glass, the composition of which is shown in Table 1.

[0043] The one-component printing ink that is used for 3C glass of table 1 embodiment 1

[0044]

[0045]

[0046] The rotation speed is 1000 rpm, while stirring, add C60 and nano-silica modified acrylic resin, C60 and nano-silica modified polyurethane resin, HDI, IPDI, water, carbon black, talcum powder, barium sulfate, carbonic acid After the calcium and additives are mixed evenly, disperse at a speed of 3000 rpm for 18 minutes, and grind on a three-roll machine to a fineness of less than 5 μm to obtain a one-component ink for 3C glass.

[0047] Take 20g of the ground one-component ink for 3C glass, use a 350-mesh screen to print, and cure in a 180°C oven for 20 minutes at a constant temperature to obtain a water-based ink coating.

Embodiment 2

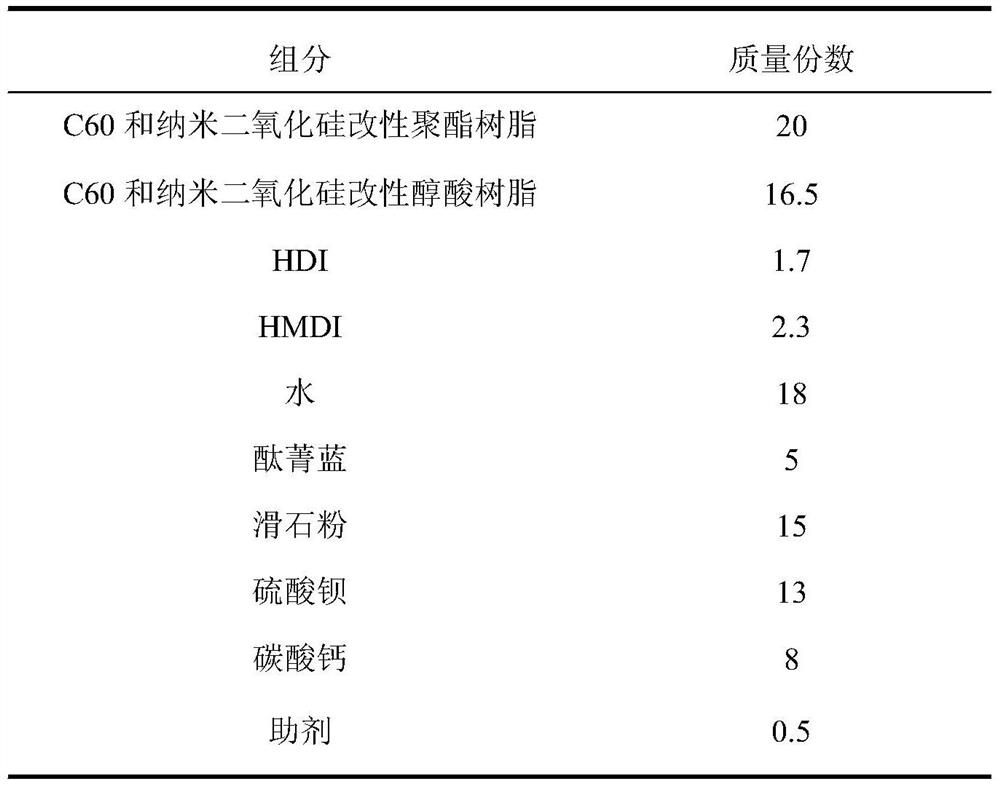

[0049] A preferred embodiment of the present invention provides a one-component ink for 3C glass, the composition of which is shown in Table 2.

[0050] The one-component printing ink that is used for 3C glass of table 2 embodiment 2

[0051]

[0052] The rotation speed is 800 rpm, while stirring, add C60 and nano-silica modified polyester resin, C60 and nano-silica modified alkyd resin, HDI, HMDI, water, phthalocyanine blue, talcum powder, sulfuric acid After the barium, calcium carbonate, and additives are mixed evenly, they are dispersed at a speed of 2500 rpm for 25 minutes, and ground on a three-roll machine to a fineness of less than 5 μm to obtain a one-component ink for 3C glass.

[0053] Take 20g of the ground one-component ink for 3C glass, use 300 mesh screen printing, and cure in a 150°C oven for 30 minutes at a constant temperature to obtain a water-based ink coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com