One-component thermal-conductive reactive flame-retardant polyurethane hot melt adhesive and preparation method thereof

A polyurethane hot-melt adhesive and reactive flame-retardant technology, which is applied in the field of structural adhesives, can solve the problems of polluted products, easy to precipitate coating surface, etc., and achieve the effects of improving flame retardancy, solving chemical resistance, and not being prone to air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

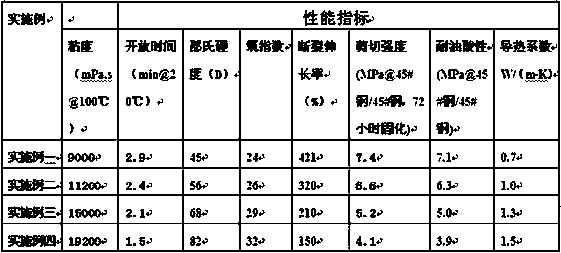

Examples

Embodiment 1

[0029] It is a one-component thermally conductive reactive flame retardant polyurethane hot melt adhesive, which is prepared by the following steps:

[0030] Step 1 Synthesis of isocyanate-modified polysilicone acrylate flame retardant copolymer

[0031]18 parts of methacryloxypropyl monoblocked dimethyl polysiloxane MAPDMS, 15 parts of allyl dimethyl phosphate DMAP, 20 parts of methyl acrylate MA and 7 parts of methacrylic acid iso The cyanoethyl ester ICEMA was dissolved in 70 parts of toluene, controlled at 80°C, and under the protection of nitrogen, 2.5 parts of thermal initiator tert-amyl peroxide 2-ethylhexanoate was added, and the polymerization reaction was carried out for 3 hours, and then removed by rotary evaporation. After toluene, the isocyanate-modified polyorganosilicon acrylate flame-retardant copolymer is obtained. The number-average molecular weight of the isocyanate-modified polyorganosilicon acrylate flame-retardant copolymer is 6000, and its chemical struc...

Embodiment 2

[0035] It is a one-component thermally conductive reactive flame retardant polyurethane hot melt adhesive, which is prepared by the following steps:

[0036] Step 1 Synthesis of isocyanate-modified polysilicone acrylate flame retardant copolymer

[0037] 25 parts of methacryloxypropyl monoblocked dimethyl polysiloxane MAPDMS, 24 parts of allyl dimethyl phosphate DMAP, 10 parts of methyl acrylate MA and 8 parts of methacrylic acid iso The cyanoethyl ester ICEMA was dissolved in 70 parts of toluene, controlled at 90°C, and under the protection of nitrogen, 1.8 parts of thermal initiator tert-amyl peroxide 2-ethylhexanoate was added, the reaction was polymerized for 15 hours, and removed by rotary evaporation. After toluene, the isocyanate-modified polyorganosilicon acrylate flame-retardant copolymer is obtained. The number-average molecular weight of the isocyanate-modified polyorganosilicon acrylate flame-retardant copolymer is 14000, and its chemical structure is: poly(methacr...

Embodiment 3

[0041] It is a one-component thermally conductive reactive flame retardant polyurethane hot melt adhesive, which is prepared by the following steps:

[0042] Step 1 Synthesis of isocyanate-modified polysilicone acrylate flame retardant copolymer

[0043] 35 parts of methacryloxypropyl monoblocked dimethylpolysiloxane MAPDMS, 40 parts of allyl dimethyl phosphate DMAP, 10 parts of methyl acrylate MA and 12 parts of methacrylic acid iso The cyanoethyl ester ICEMA was dissolved in 100 parts of toluene, controlled at 85°C, and under the protection of nitrogen, 1.2 parts of thermal initiator tert-amyl peroxide 2-ethylhexanoate was added, and the polymerization reaction was carried out for 9 hours, and removed by rotary evaporation. After toluene, the isocyanate-modified polyorganosilicon acrylate flame-retardant copolymer is obtained. The number-average molecular weight of the isocyanate-modified polyorganosilicon acrylate flame-retardant copolymer is 21000, and its chemical structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com