Fluorine-free efficient dephosphorizing agent for pretreatment of chromium-containing molten iron

The technology of molten iron pretreatment and dephosphorization agent is applied in the field of iron and steel metallurgy, which can solve the problems of low dephosphorization rate, difficulty in slag removal, environmental pollution of dephosphorization agent, etc. The effect of improving slag fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] In this embodiment, the mass percentages of the components of the dephosphorization agent for chromium-containing molten iron are: 6% CaO, 20% BaCO 3 , 50.5% Fe 2 o 3 , 12.5% CAF 2 , 5%Cr 2 o 3 , 6% CeO 2 .

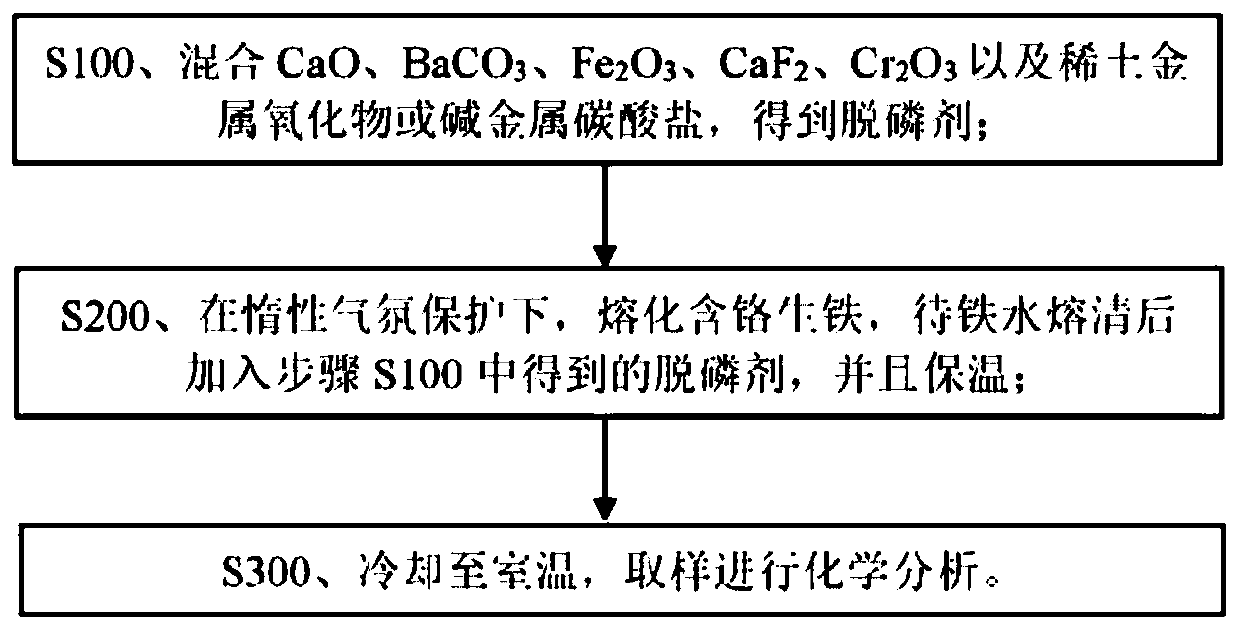

[0045] Such as figure 1 As shown, the powders of the above components are mixed according to the set ratio to make slag. Put pig iron (by mass percentage, [%C] = 4.23%, [%P] = 0.130%, [%Cr] = 0.25%, [%Si] = 0.34%) into the alumina crucible, the outer graphite crucible Put it into the muffle furnace and raise the temperature to 1400°C, and pass it into the argon gas protection until the pig iron is completely melted, then add the slag to the molten iron at a mass ratio of 1:5, stir it with a steel rod every 5 minutes, and keep it warm After 25 minutes, the crucible was taken out, placed in cooling water and rapidly cooled to room temperature.

[0046] The chemical analysis of the iron sample shows that after dephosphorization treatment, the silicon conten...

Embodiment 2

[0048] The basic content of this embodiment is the same as that of Example 1, except that in this embodiment, the mass percentages of the components of the dephosphorization agent for molten iron containing chromium are: 6% CaO, 20% BaCO 3 , 50.5% Fe 2 o 3 , 12.5% CaF 2 , 5%Cr 2 o 3 , 6% La 2 o 3 .

[0049] Mix the powders of the above components according to the set ratio to make slag. Add pig iron (by mass percentage, [%C]=3.81%, [%P]=0.120%, [%Cr]=0.25%, [%Si]=0.31%) into the alumina crucible, and coat the graphite crucible Put it into the muffle furnace and raise the temperature to 1400°C, and pass it into the argon gas protection until the pig iron is completely melted, then add the slag to the molten iron at a mass ratio of 1:5, stir it with a steel rod every 5 minutes, and keep it warm After 25 minutes, the crucible was taken out, placed in cooling water and rapidly cooled to room temperature.

[0050] The chemical analysis of the iron sample shows that after...

Embodiment 3

[0052] The basic content of this embodiment is the same as that of Example 1, except that in this embodiment, the mass percentages of the components of the dephosphorization agent for molten iron containing chromium are: 6% CaO, 20% BaCO 3 , 50.5% Fe 2 o 3 , 12.5% CaF 2 , 5%Cr 2 o 3 , 6%Li 2 CO 3 .

[0053] Mix the powders of the above components according to the set ratio to make slag. Add pig iron (by mass percentage, [%C] = 4.26%, [%P] = 0.16%, [%Cr] = 0.25%, [%Si] = 0.32%) into the alumina crucible, the outer graphite crucible Put it into the muffle furnace and raise the temperature to 1400°C, and pass it into the argon gas protection until the pig iron is completely melted, then add the slag to the molten iron at a mass ratio of 1:5, stir it with a steel rod every 5 minutes, and keep it warm After 25 minutes, the crucible was taken out, placed in cooling water and rapidly cooled to room temperature.

[0054] The chemical analysis of the iron sample shows that a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com