Manufacturing method of zinc-aluminum alloy coated steel strand with medium-high aluminum content

A zinc-aluminum alloy and manufacturing method technology, which is applied in the direction of manufacturing tools, metal material coating technology, coating, etc., can solve the problems of reduced service life, strength and other mechanical properties that cannot meet the specification requirements, and achieve long service life and extension The effective working life and the effect of reducing the number of cable replacements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The manufacturing method of the 1860MPa-grade zinc-aluminum alloy-coated steel strand product for high-strength and durable bridge cables comprises the following steps:

[0047] (1) selection of wire rod

[0048] Special high-quality high-carbon steel wire rods are selected. The wire rods are ultra-pure, hypereutectoid steel high-carbon steel wire rods that have been sorbitized. The diameter of the wire rods is 13mm. Rate ≥ 30%. The chemical composition is calculated by mass percentage as C: 0.79-0.86%, Si: 0.15-0.35%, Mn: 0.60-0.90%, P≤0.025%, S≤0.025%, Cr≤0.35%, Cu≤0.20%, metallographic Satisfied with the structure: decarburization layer ≤ 0.07%, grain size 7, sorbite ≥ 85%, no martensite and reticular cementite structure; wire rod for decarburization layer depth inspection: total decarburization on one side of the wire rod The depth of the layer (ferrite + transition layer) shall not be greater than 1.5% of the nominal diameter of the wire rod.

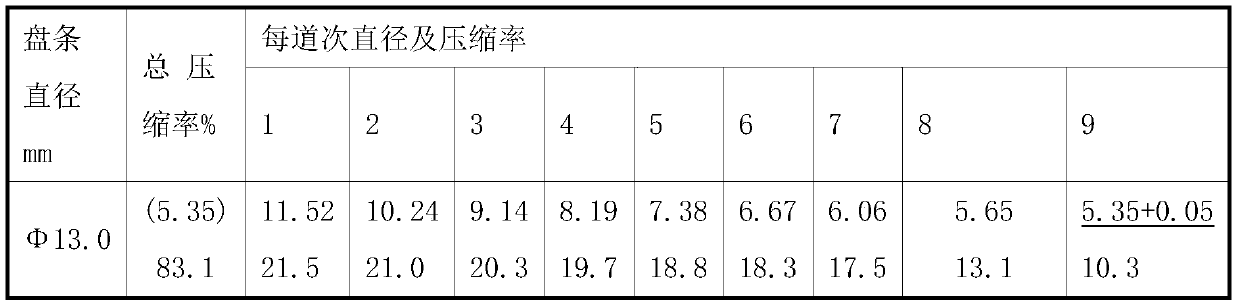

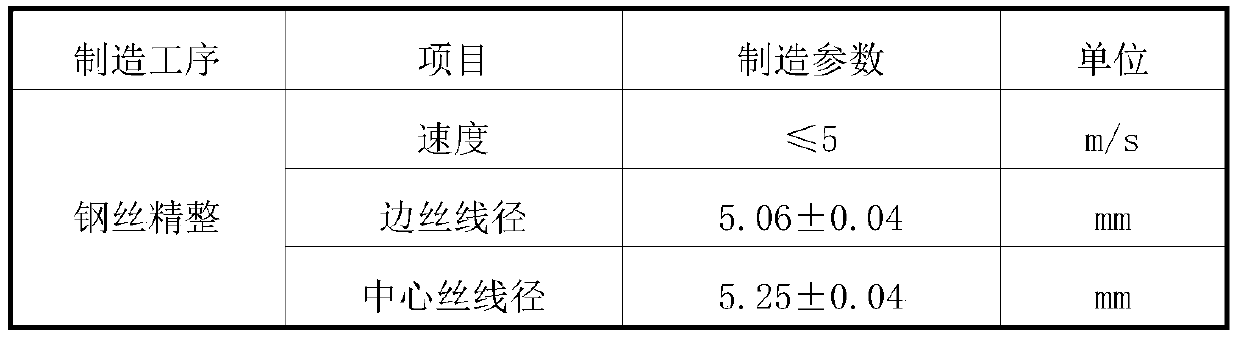

[0049] (2) Pre-tr...

Embodiment 2

[0083] The method for preparing zinc-aluminum alloy coated steel strand with medium aluminum content, the steps are as follows

[0084] (1) selection of wire rod

[0085] Referring to Embodiment 1, the wire rod of Φ13mm is selected in this embodiment.

[0086] (2) Pre-treatment of wire rod

[0087] Specific steps include,

[0088] Pickling the wire rod, the concentration of hydrochloric acid in the pickling solution is 200g / L, the concentration of ferrous iron is 160g / L, pickling for 30min;

[0089] After washing with clean water, rinse with high-pressure water for 1 min;

[0090] Boronation: put the rinsed wire rod into the boronization tank for 20 minutes, the temperature of the boronization tank is higher than ≥90°C, and the boronization concentration is 110g / L;

[0091] Put the phosphating wire rod into the lime tank and keep it for 10 minutes. The pH value of the lime in the lime tank is ≥6 and the temperature is ≥90°C, and then the wire rod is air-dried.

[0092] (3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com