A device and method for observing bubble behavior on electrode surface

A technology of electrode surface and air bubbles, which is applied in the direction of measuring devices, electrochemical variables of materials, and material analysis through optical means, to achieve the effects of high detection response, improved detection efficiency, and sensitive detection response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

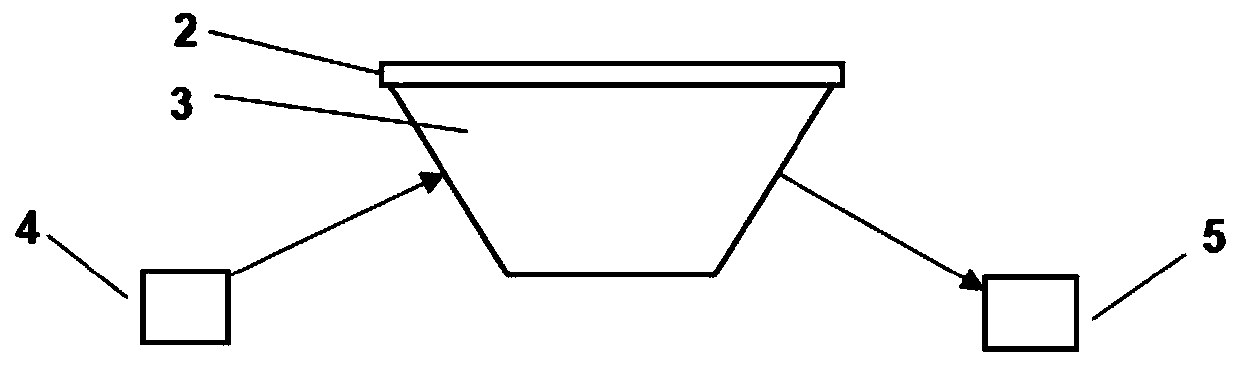

Method used

Image

Examples

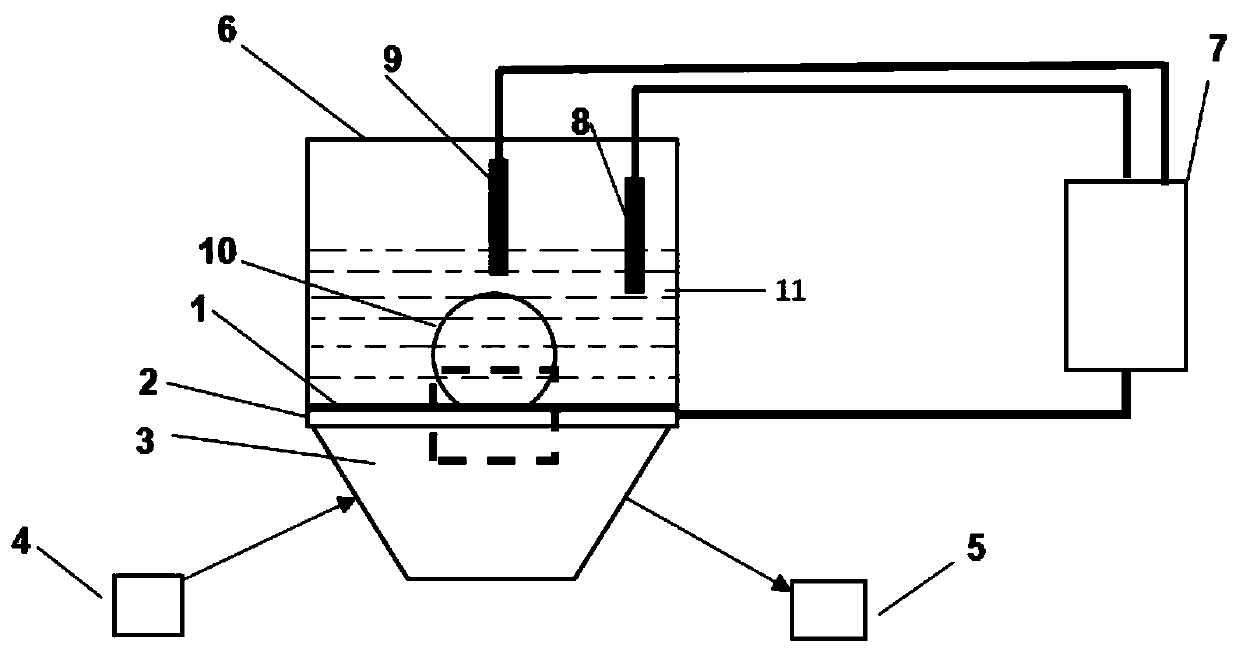

Embodiment 1

[0063] Deposit a layer of platinum under potential on the gold surface of the prism of the surface plasmon resonance analysis imaging device to form the working electrode layer 1, the counter electrode 8 is a platinum wire, and the reference electrode 9 is a saturated calomel electrode, and connect the working electrode layer 1, The counter electrode 8 , the reference electrode 9 and the electrochemical workstation 7 perform a constant potential hydrogen evolution reaction at -0.3v in a system with 0.5mol / L sulfuric acid as the electrolyte to generate bubbles 10 . The electrochemical workstation 7 records the change of current and voltage with time; the light intensity detector 5 records the change of reflectivity with time, and obtains a series of SPRi differential diagrams of the bubble 10 growth process, through which the SPRi differential diagram can be observed The contact area between the air bubbles 10 and the working electrode layer 1 changes with time, and the instant ...

Embodiment 2

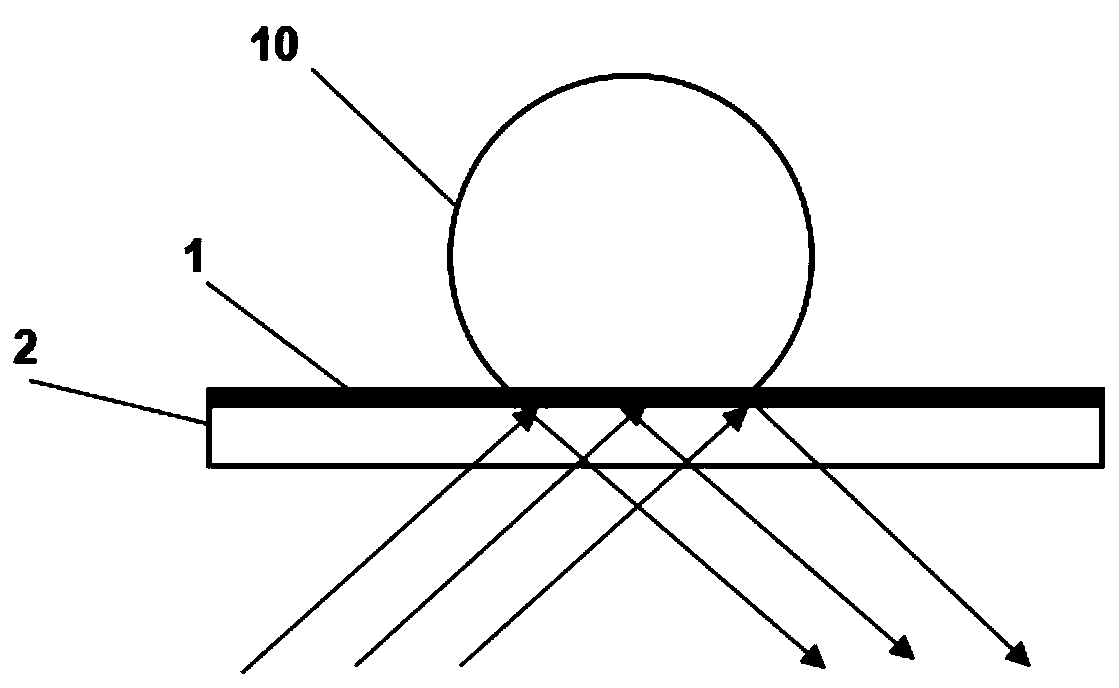

[0067] The analysis method of information such as the contact angle of the bubble 10 on the surface of the working electrode layer 1, the diameter of the bubble 10, the volume and surface area of the bubble 10, and the growth rate of the bubble 10 is as follows:

[0068] Under the same reaction conditions as in Example 1, the growth process of the bubbles 10 was observed by a high-speed camera at the same time, and video recording was performed, and the images at each moment were measured by software to obtain the growth of the bubbles 10 on the surface of the working electrode layer 1. Contact angle.

[0069] Further, other parameters of the bubble 10 are calculated through the contact angle obtained by the high-speed camera analysis and the bottom surface radius obtained by the SPRi analysis, such as the radius and diameter of the bubble 10, the volume and surface area of the bubble 10, the Growth rate of bubble 10. Wherein, the radius of the bottom surface, that is, th...

Embodiment 3

[0080] Gas repellency test of the working electrode layer 1:

[0081] Using the device described in Example 1, put part of the device including the working electrode layer 1 into an oxygen plasma cleaning machine for cleaning for 10 minutes to achieve hydrophilic treatment, and the other experimental conditions are the same as in Example 1.

[0082] In this embodiment, three points in the bubble growth process are selected in sequence according to time, and the bubble growth time t is 3s, 18s, and 51s respectively, and the SPRi difference diagram during the bubble growth process of the gas-repellent electrode is obtained Figure 7 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com