Integrated processing method and device for gasifiable coal

A processing method and technology for gasifying coal, which can be applied in sustainable manufacturing/processing, chemical industry, granular/powder fuel gasification, etc., can solve the problems of easy explosion, complicated process, low efficiency, etc., and achieve low operating costs, The effect of high combustion efficiency and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

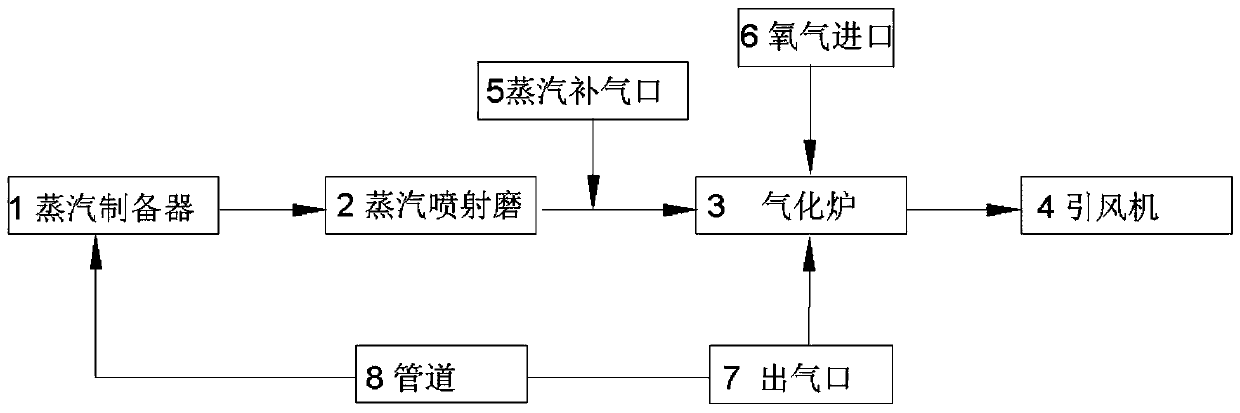

[0032] The gasification coal integrated processing device includes a steam generator 1, a steam injection mill 2, a gasification furnace 3 and an induced draft fan 4 connected in sequence, and the gasification coal gasification furnace 3 is equipped with a steam supplementary The gas port 5, the gasifier 3 is provided with an oxygen inlet 6. The flue gas outlet of the gasifier 3 is connected to the steam generator 1 through a pipe 8 .

[0033] An integrated processing method for gasification coal, comprising the following steps:

[0034] (1) finely crushing and drying the gasifiable coal in the raw material bin through the steam jet mill 2 to obtain a gasifiable coal powder mixture;

[0035] (2) The gasifiable pulverized coal mixture is transported to the classifier by airflow for classification;

[0036] (3) The coarse gasifiable pulverized coal mixture with a particle size greater than 90 μm is returned to the steam jet mill for ultra-fine pulverization, and the fine gasif...

Embodiment 2

[0046] The gasification coal integrated processing device includes a steam generator 1, a steam injection mill 2, a gasification furnace 3 and an induced draft fan 4 connected in sequence, and the gasification coal gasification furnace 3 is equipped with a steam supplementary Gas port 5, the gasifier 3 is provided with an oxygen inlet. The flue gas outlet of the gasifier 3 is connected to the steam generator 1 through a pipe 8 .

[0047] An integrated processing method for gasification coal, comprising the following steps:

[0048] (1) Finely pulverize and dry the gasifiable coal in the raw material bin through a steam jet mill to obtain a gasifiable coal powder mixture;

[0049] (2) The gasifiable pulverized coal mixture is transported to the classifier by superheated air flow for classification;

[0050] (3) The coarse gasifiable pulverized coal mixture with a particle size greater than 90 μm is returned to the steam jet mill for ultra-fine pulverization, and the fine gasi...

Embodiment 3

[0060] The gasification coal integrated processing device includes a steam generator 1, a steam injection mill 2, a gasification furnace 3 and an induced draft fan 4 connected in sequence, and the gasification coal gasification furnace 3 is equipped with a steam supplementary Gas port 5, the gasifier 3 is provided with an oxygen inlet. The flue gas outlet of the gasifier 3 is connected to the steam generator 1 through a pipe 8 .

[0061] An integrated processing method for gasification coal, comprising the following steps:

[0062] (1) Finely pulverize and dry the gasifiable coal in the raw material bin through a steam jet mill to obtain a gasifiable coal powder mixture;

[0063] (2) The gasifiable pulverized coal mixture is transported to the classifier by superheated air flow for classification;

[0064] (3) The coarse gasifiable pulverized coal mixture with a particle size greater than 90 μm is returned to the steam jet mill for ultra-fine pulverization, and the fine gasi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com