High-throughput algae culture and test method

A testing method and technology of an algae cultivation system are applied in the field of high-throughput algae cultivation and testing, which can solve the problems of difficulty in meeting the scientific research needs of algal cells, high dependence on manpower, time-consuming and laborious, and save research time and manpower costs. The system is small and the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] This example is to illustrate the high-throughput algae cultivation and testing method of the present invention.

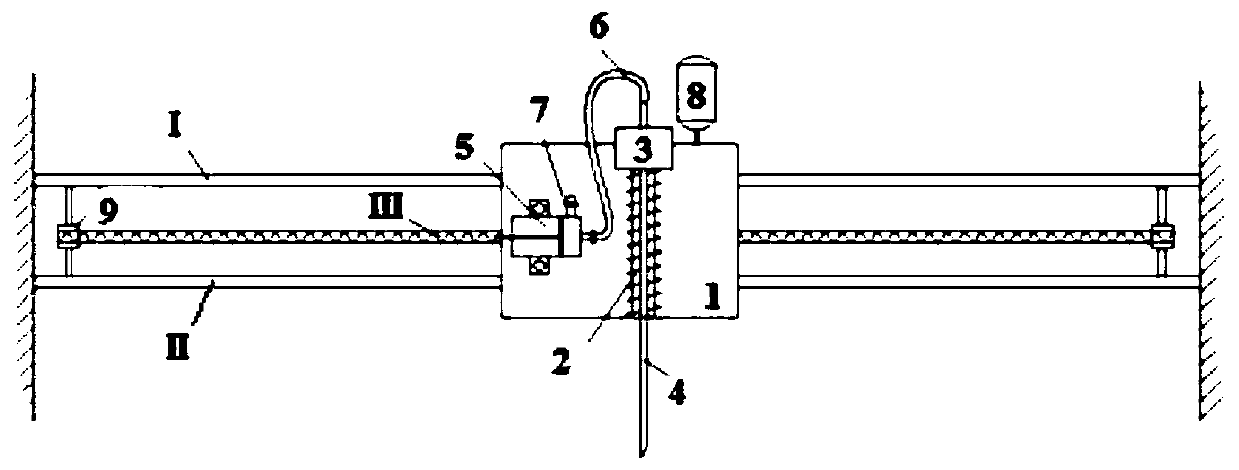

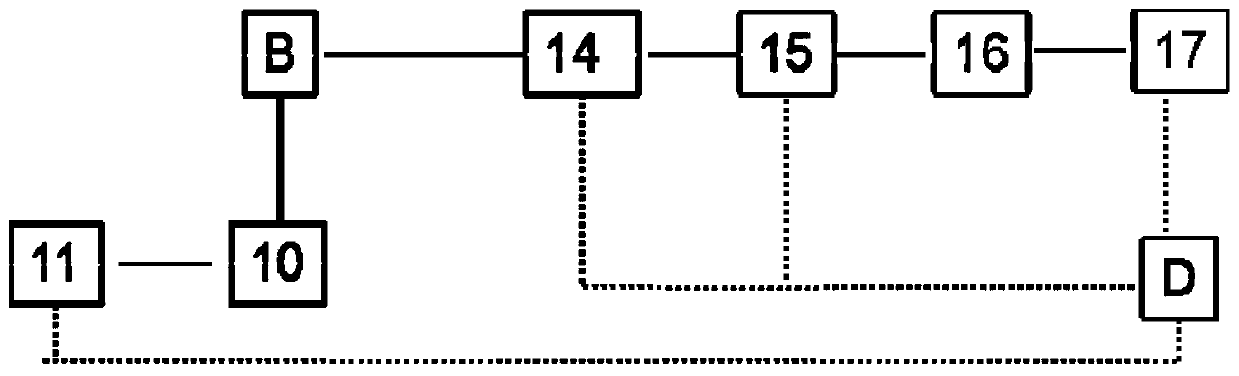

[0077] combine figure 1 with figure 2 ,specifically:

[0078] (H1) Cultivate algae in the photobioreactor array 10 in the high-throughput algae cultivation system;

[0079] (H2) The first stepper motor 3 drives the probe 4 to move horizontally, front-to-back, and vertically on the screw guide rail 2 at 5mm / min, and the second stepper motor 8 passes through the tooth groove structure on the gear and positioning belt III Mesh together, drive the displacement platform 1 to move horizontally, front-to-back and vertically at 5mm / min on the positioning belt III, and then drive the moving distance of the probe 4 to realize the precise positioning of the probe 4;

[0080] (H3) By controlling the one-way valve 7 on the sampling pump 5, sampling is realized through the flexible pipe 6. After sampling, the sampling pump 5 is idling, and all the liquid taken can be...

Embodiment 2

[0087] Carry out high-throughput algae culture and test according to the same method as Example 1, the difference is: the first stepping motor 3 drives the probe 4 on the screw guide rail 2 at 4mm / min in the horizontal, front and back and vertical directions Move, the second stepping motor 8 meshes with the cogged structure on the positioning belt III through the gear, and drives the displacement platform 1 to move horizontally, front-to-back and vertically at 4 mm / min on the positioning belt III; the photobioreactor array 10 The number of layers is 5 layers, and each layer includes 24 reactor units.

[0088] Results The automatic sampling frequency of the sampler can reach 2 samples / min, the sampling volume is 100 mL, and the sampling precision is 105 μL.

Embodiment 3

[0090] Carry out high-throughput algae culture and test according to the same method as Example 1, the difference is: the first stepper motor 3 drives the probe 4 on the screw guide rail 2 at 3mm / min in the horizontal, front and rear and vertical directions To move, the second stepper motor 8 meshes with the cog structure on the positioning belt III through the gear, and drives the displacement platform 1 to move horizontally, front and rear, and vertically at 3mm / min on the positioning belt III.

[0091] Results The automatic sampling frequency of the sampler can reach 2 samples / min, the sampling volume is 90 mL, and the sampling accuracy is 100 μL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com