Graphene-silicon-based composite negative electrode material for lithium ion battery and preparation method thereof

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of material conductivity, danger, and difficult material scale preparation, etc., to improve conductivity, ensure continuous performance, Effect of improving structural stability and cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

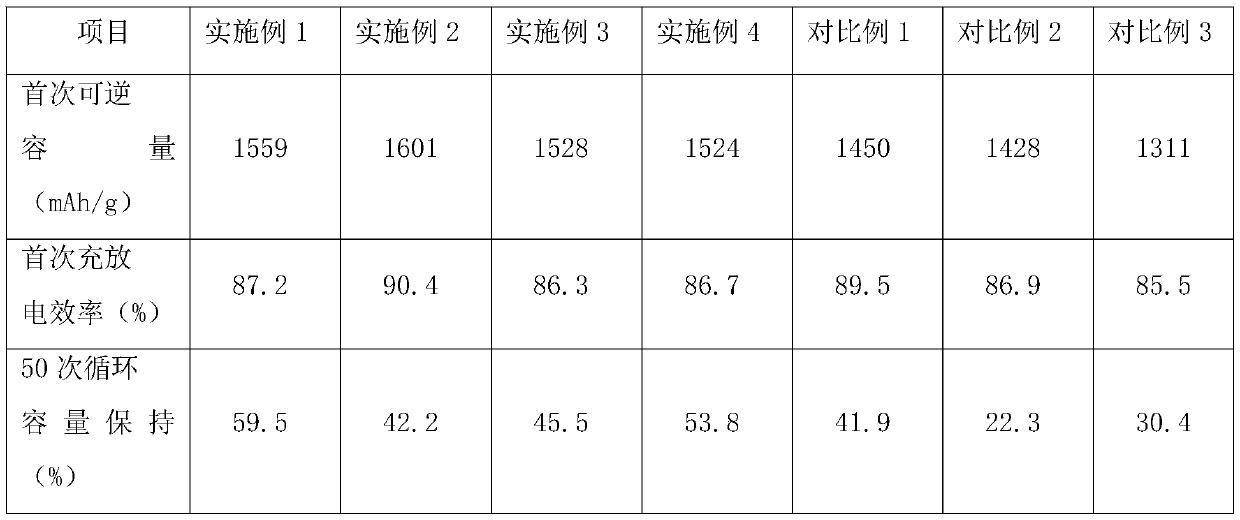

Examples

preparation example Construction

[0025] The preparation method of the graphene-silicon-based composite negative electrode material for lithium ion batteries of the present invention comprises the following steps:

[0026] Step 1, adding nano-silicon, graphene, and graphite in a certain proportion to a ball-milling jar for ball-milling for a certain period of time to obtain a uniformly mixed material 1;

[0027] Step 2, add the material 1 and the organic carbon source into the organic solvent, stir and mix, and disperse evenly, then place in a water bath and heat to 70-90°C, heat and stir until the organic solvent evaporates to dryness, and vacuum dry at 60-100°C Overnight, material 2 was obtained.

[0028] In step 3, the obtained material 2 is extruded and granulated by a tablet machine, and then heated to 150-300 °C to maintain a constant temperature, and after the organic carbon source is completely melted, the temperature is raised to 700-950 °C for high-temperature carbonization to obtain organic cracked ...

Embodiment 1

[0037] A method for preparing a graphene-silicon-based composite negative electrode material of the present invention, comprising the following steps:

[0038] Nano-silicon, graphene, and artificial graphite with a particle size of less than 300 nm and a particle size of about 5 μm were added to the ball milling tank for 300 min in a certain proportion, wherein the ball-to-material ratio was 10:1, the rotational speed was 500 rpm, and the solid content was 50%. Then stir and mix with pitch in ethanol for 2 hours (wherein the residual carbon ratio of pitch is 41%, and the mass ratio of nano-silicon:graphene:graphite:pitch cracked carbon is 45.5:4.5:25:25), and heated to 70 in a water bath It was heated and stirred at ℃ until the ethanol was evaporated to dryness, and then vacuum-dried at 60 ℃ overnight. The mixture was extruded and pelletized with a tablet machine, heated to 200 °C to maintain a constant temperature for 2 hours, and the heating rate was 5 °C / min. After the asph...

Embodiment 2

[0041] A method for preparing a graphene-silicon-based composite negative electrode material of the present invention, comprising the following steps:

[0042]The nano-silicon, graphene, and artificial graphite with a particle size of less than 300 nm and a particle size of about 5 μm were added to the ball mill in a certain proportion for ball milling for 180 minutes, wherein the ball-to-material ratio was 6:1, the rotational speed was 500 rpm, and the solid content was 50%. Then stir and mix with pitch in ethanol for 2 hours (wherein the residual carbon ratio of pitch is 41%, and the mass ratio of nano-silicon:graphene:graphite:pitch cracked carbon is 45.5:4.5:25:25), and heated to 70 in a water bath It was heated and stirred at ℃ until the ethanol was evaporated to dryness, and then vacuum-dried at 60 ℃ overnight. The mixture was extruded and pelletized with a tablet machine, heated to 200 °C to maintain a constant temperature for 2 hours, and the heating rate was 5 °C / min....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com