Phosphor powder capable of promoting plant growth and preparation method thereof

A technology for promoting plant growth and phosphor powder, applied in the fields of botanical equipment and methods, plant growth regulators, plant growth regulators, etc. problem, to achieve the effect of improving the utilization rate of light energy, low price and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The present invention also provides a kind of preparation method of above-mentioned fluorescent powder, specifically carries out according to the following steps:

[0040] 1) Press Al (2-x) o 3 :xCr 3+(In the formula, 0.005≤x≤0.06) The stoichiometric ratio of each chemical composition in the chemical expression weighs the first aluminum compound and chromium compound respectively, and mixes and grinds the first aluminum compound and chromium compound to micron level to obtain the first a powder;

[0041] The first aluminum compound is aluminum oxide (Al 2 o 3 ), aluminum-containing hydroxides, aluminum-containing nitrates, aluminum-containing sulfates or aluminum-containing phosphates, etc.

[0042] Chromium compound adopts chromium oxide (Cr 2 o 3 ), chromium-containing hydroxide, chromium-containing nitrate, chromium-containing carbonate, chromium-containing sulfate or chromium-containing phosphate, etc.

[0043] 2) Place the first powder prepared in step 1) i...

Embodiment 1

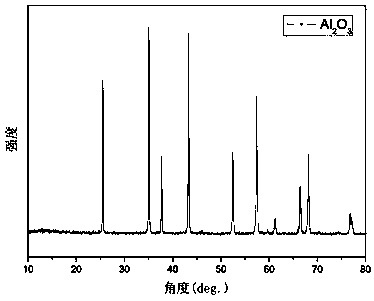

[0054] Press Al 1.98 o 3 :0.02Cr 3+ The stoichiometric ratio shown in the molecular formula, weigh 1.9698g of Al 2 o 3 and 0.0297g of Cr 2 o 3 , will weigh the Al 2 o 3 and Cr 2 o 3 After grinding and mixing evenly, put it into an alumina crucible, place it in an environment with a temperature of 1450°C and calcinate it under a nitrogen atmosphere for 4 hours, and cool it to room temperature with the furnace to obtain a calcined product; after grinding, a powder is obtained. The XRD pattern of the powder is as follows figure 1 As shown, the peak shape and peak position in the figure correspond to the PDF card one by one. On this basis, through structure refinement, it is proved that the phase of the prepared powder is Al 2 o 3 Simplex.

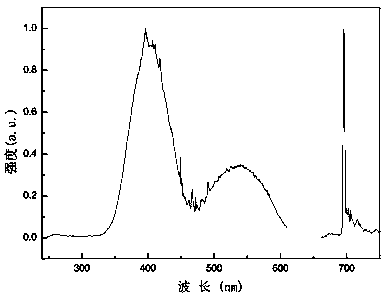

[0055] Excitation and emission spectra of the prepared powders, such as figure 2 As shown, the excitation spectrum shows that there are two broad peaks, the peaks are located at 400nm and 550nm respectively, and the emission spec...

Embodiment 2

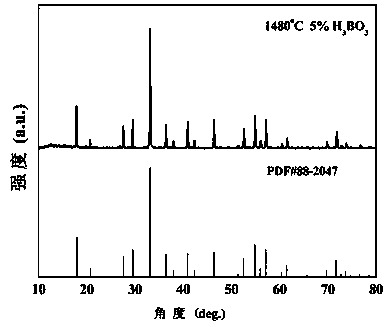

[0057] press Y 2.94 Al 5 o 12 :0.06Ce 3+ For the stoichiometric ratio shown in the molecular formula, weigh 1.1117g of Y 2 o 3 , 0.0346g of CeO 2 and 0.8535g of Al 2 o 3 , and then weighed 0.1gH 3 BO 3 (5wt%) as a co-solvent, mixed and ground the weighed materials evenly, put them into an alumina crucible, and calcined for 4 hours in a reducing atmosphere at a temperature of 1480 ° C. The reducing atmosphere was composed of 95% by volume nitrogen and 5 % hydrogen composition, the calcined powder is cooled to room temperature with the furnace to obtain the calcined product; after grinding, the powder is obtained. The XRD spectrum of the powder is as follows image 3 shown, from image 3 It can be seen that the peaks of the powder correspond to the PDF card one by one, and there are no miscellaneous peaks. On this basis, the structure is refined, which proves that the phase of the powder is YAG:Ce 3+ Simplex. Figure 4 For the YAG that embodiment 2 makes: Ce 3+ The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com