Preparation method and application of V-shaped groove of micro-fluidic chip injection mold and preparation method of micro-fluidic chip

A technology of microfluidic chips and injection molds, applied in chemical instruments and methods, electrode manufacturing, manufacturing tools, etc., can solve the problems of poor depth consistency, large surface roughness, tool wear and processing surface quality, etc., to achieve guaranteed Consistency and repeatability, surface quality assurance, and shape-forming results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

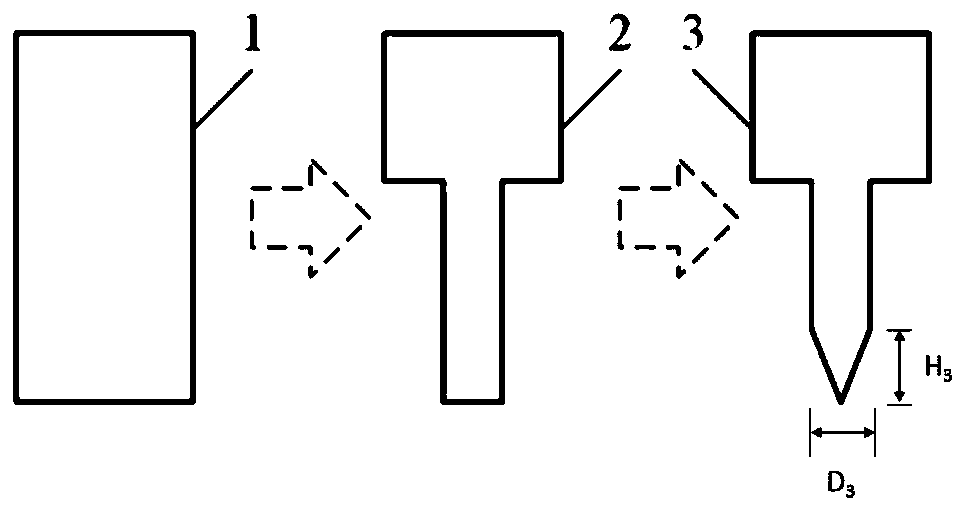

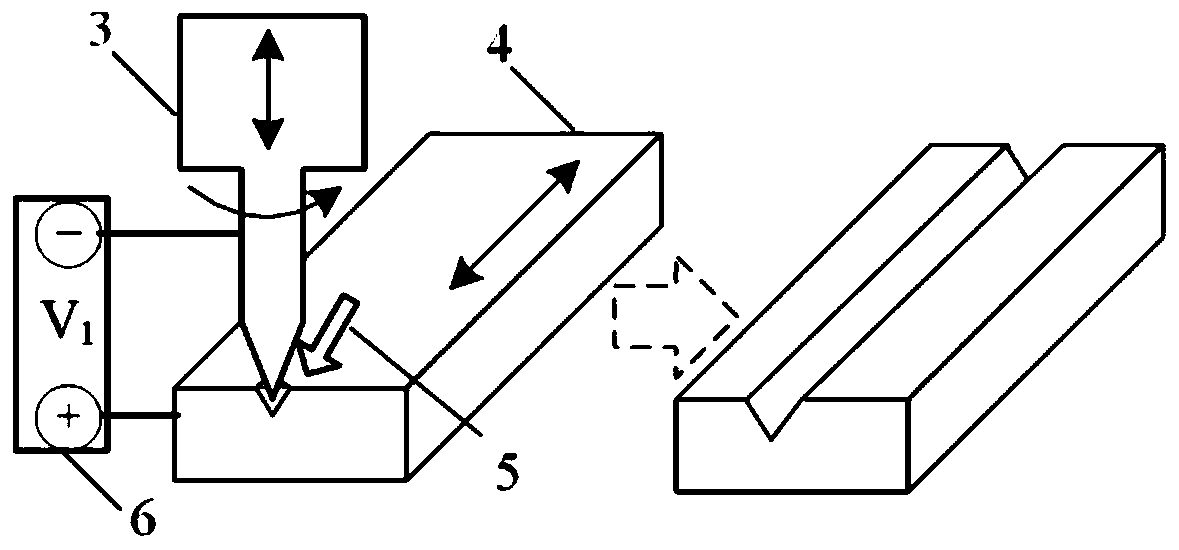

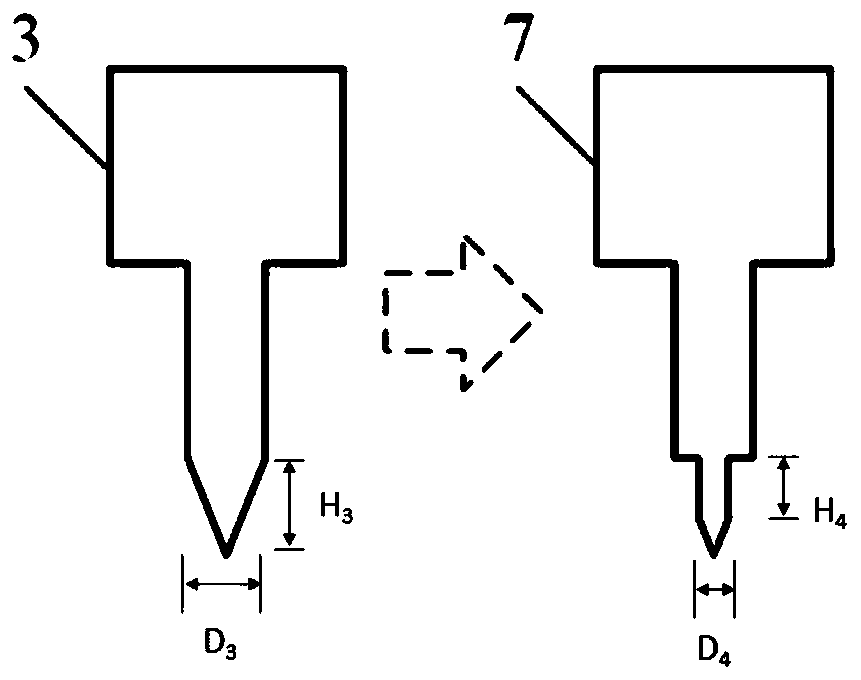

[0077] The invention aims to solve the high-quality manufacturing problem of the V-groove of the microfluidic chip injection mold. For V-shaped grooves with high hardness of injection mold material, small structure and sharp shape, and high surface quality requirements, the present invention provides a V-shaped linear groove and curved groove that can realize angles and smaller rounded corners in injection mold processing. method. The preparation method of the V-shaped groove of the microfluidic chip injection mold provided by the present invention includes providing a third micro-conical electrode with a conical tip to process the workpiece into the main body profile of the V-shaped groove, and then further forming the third micro-conical electrode The electrode is trimmed into a fourth tip conical electrode with a smaller cone height and angle, which is used to further modify the main body contour of the V-shaped groove to obtain a V-shaped groove with a smaller rounded corn...

Embodiment 1

[0109] The combined processing technology of a microfluidic chip injection mold core provided by the present invention will be described below with reference to the accompanying drawings and specific embodiments. This embodiment provides a method for preparing a V-shaped groove of an injection mold for a microfluidic chip, and the V-shaped groove is a linear groove structure. Among them, S136H mold steel is used as the workpiece material. S136H material is a plastic mold steel with excellent corrosion resistance. It has the characteristics of corrosion resistance, strain resistance, wear resistance, and easy to obtain a high-gloss surface. , the hardness can be tempered to 50HRC, and can be injected many times without deformation. After the mold made of this material is used for a long time, the surface of the mold can still maintain the original smooth state, and it does not need special protection when it is operated or stored in a humid environment.

[0110] The preparatio...

Embodiment 2

[0116] This embodiment provides a method for processing a V-shaped groove with an obtuse angle asymmetric structure curve, wherein the mechanism elements and workpiece materials indicated by the icons are the same as those in Embodiment 1. The specific steps and parameters are as follows:

[0117] (a) The first cylindrical electrode 1 made of tungsten and having a diameter of 500 μm is processed into a diameter D by using a wire electric discharge grinding (WEDG: Wire Electrical Discharge Grinding) method. 3 The second fine cylindrical electrode 2 is 164 μm. Utilize the plate electrode 8 that the material is copper to incline 30 °, by electrolytic back-copying the second micro cylindrical electrode 2, make the 3rd micro conical electrode 3 with 115 ° cone angle, refer to Figure 5 Shown, the cone height H 3 is 49 μm. The processing parameters of electrolytic reverse copying are: pulse voltage 8V, duty cycle 5: 5μs, electrolyte 1mol / L NaClO 3 And 0.01mol / L sodium citrate. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com