Biogas purification membrane bioreactor and biogas purification process system thereof

A membrane bioreactor and reactor technology are applied in the field of biogas purification process systems, which can solve the problems of high energy consumption and secondary environmental pollution, and achieve the effects of strong environmental adaptability, enhanced mass transfer speed, and uniform distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

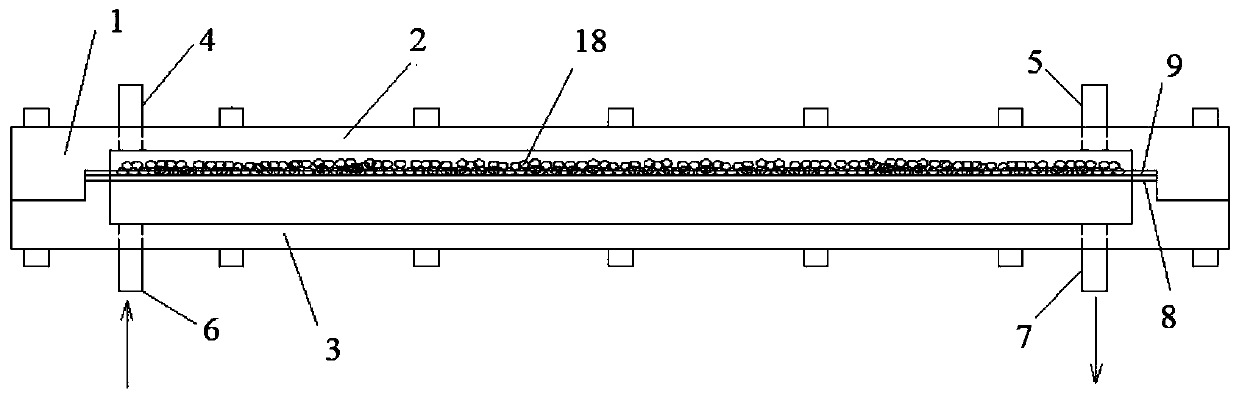

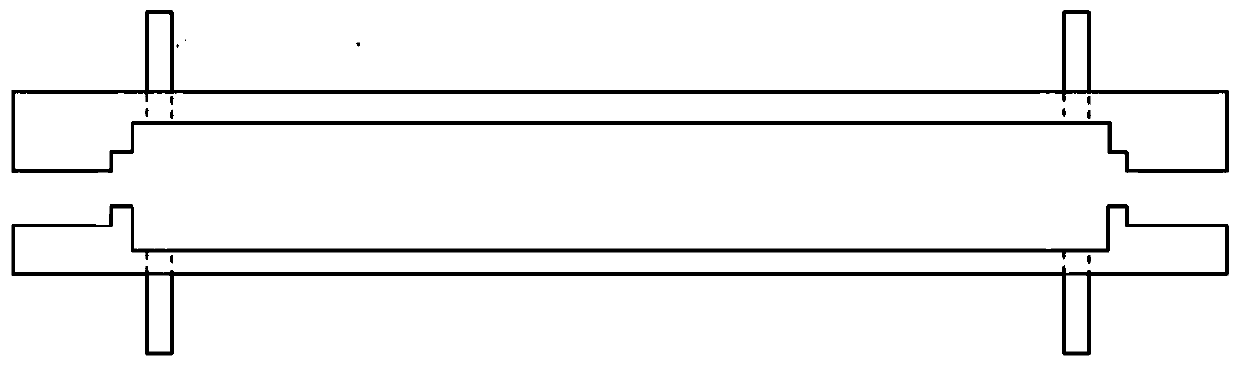

[0032] Such as figure 1 and 2 As shown, a membrane bioreactor for biogas purification includes a reactor body 1, the reactor body 1 is a cuboid with closed ends, its height is 25 mm, its length is 250 mm, its width is 70 mm, and its total volume is 0.44 L. The effective volume is 0.27L; the shape can be flexibly selected as a cylinder according to actual needs, and the material is transparent and sealed plexiglass, and polyethylene, polypropylene or polyvinyl chloride can also be used.

[0033] The reactor body 1 is divided into an upper shell 2 and a lower shell 3 , the upper shell 2 and the lower shell 3 form a reaction tank inside, a liquid phase chamber in the upper shell 1 , and a gas phase chamber in the lower shell 2 . The top of the upper shell 2 is provided with a reactor circulating water inlet 4 and a reactor circulating water outlet 5. The reactor circulating water inlet 4 and the reactor circulating water outlet 5 are respectively located at the two ends of the u...

Embodiment 2

[0038] A membrane bioreactor for biogas purification, including a reactor body 1, the reactor body 1 is a cuboid with two ends closed, its height is 50mm, its length is 500mm, its width is 140mm, its total volume is 0.88L, and its effective volume is The volume is 0.54L, and the effective volume is 0.27L; the shape can be flexibly selected as a cylinder according to actual needs, and the material is transparent and sealed organic glass, and polyethylene, polypropylene or polyvinyl chloride can also be used.

[0039] The reactor body 1 is divided into an upper shell 2 and a lower shell 3 , the upper shell 2 and the lower shell 3 form a reaction tank inside, a liquid phase chamber in the upper shell 1 , and a gas phase chamber in the lower shell 2 . The top of the upper shell 2 is provided with a reactor circulating water inlet 4 and a reactor circulating water outlet 5. The reactor circulating water inlet 4 and the reactor circulating water outlet 5 are respectively located at t...

Embodiment 3

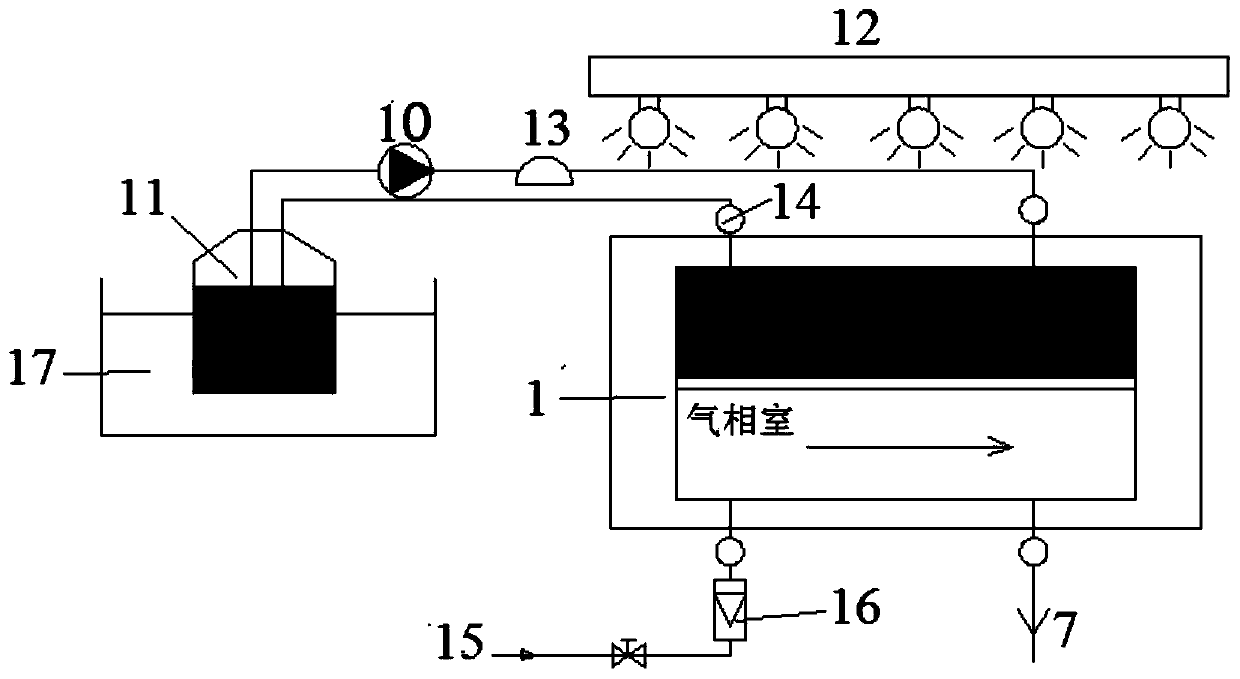

[0044] Such as image 3 As shown, a biogas purification process system includes the membrane bioreactor for biogas purification of Example 1, a circulating fluid storage bottle 11, a peristaltic pump 10, a pulse damper 13, a liquid phase sampling port 14, a gas cylinder 15, a gas Flow meter 16, water bath 17, lighting system 12; circulating fluid storage bottle 11 is located in water bath 17, and is connected with peristaltic pump 10, pulse damper 13, reactor circulating water inlet 4 of reactor body 1 in turn, and then through The reactor circulating water outlet 5 is connected back to the circulating fluid storage bottle 11; the gas cylinder 15 is connected to the reactor inlet 6 of the reactor body 1 through a gas flow meter 16, and the purified biogas is provided with an air bag through the gas outlet 7 For collection; the lighting system 12 is arranged at the upper end outside the reactor body.

[0045] During the biogas purification process, the peristaltic pump 10 pump...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com