Modified carbon black particle and preparation method and application thereof

A technology for modifying carbon black and carbon black particles, which is applied in dyeing physical treatment, fibrous fillers, etc. It can solve the problems of increased thickness of graphene sheets, difficulty in dispersion, and generation of smoke, so as to prevent agglomeration and uniform dispersion , saving time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

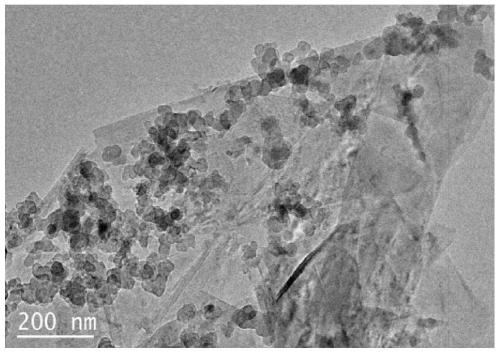

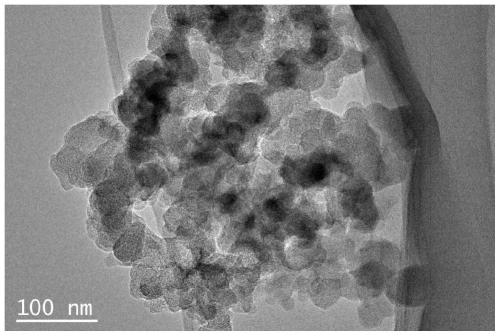

Image

Examples

Embodiment 1

[0046] The present embodiment provides a kind of preparation method of modified carbon black particle, concrete steps are as follows:

[0047] (1) preparation double-layer graphene concentration is the aqueous solution of 5%, adds 0.2% lignosulfonate dispersant, evenly disperses, obtains double-layer graphene dispersion liquid (pH is 7), the multi-layer graphene solution is mixed with The carbon black granulation water that molasses concentration is 50% is mixed according to volume ratio 2:1, obtains mixed solution (wherein the concentration of bilayer graphene is 3.3%, and the concentration of described molasses is 16.7%);

[0048] Wherein, the thickness of the bilayer graphene sheet is 2nm.

[0049] (2) The mixed solution is atomized and sprayed into the granulation bin under the pressure of 0.4MPa, and the pyrolytic carbon black powder is added into the granulation bin under the action of the induced draft fan for granulation, Control the volume ratio of the mixed solution...

Embodiment 2

[0053] The difference from Example 1 is that in step (1), an aqueous solution with a double-layer graphene concentration of 2.5% is configured.

[0054] Compared with the unmodified carbon black particles, the resistance of the modified carbon black particles was reduced by 30.5%.

Embodiment 3

[0056] The difference from Example 2 is that pyrolytic carbon black is replaced by conductive carbon black.

[0057] Compared with the unmodified carbon black particles, the resistance of the modified carbon black particles was reduced by 25.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com