Multi-responsive intelligent nano fiber functional material and preparation method and application thereof

A technology of nanofibers and functional materials, applied in the field of multi-responsive smart nanofiber functional materials and their preparation, can solve problems such as influence and achieve good pH responsiveness and temperature responsiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The preparation of the multi-responsive intelligent nanofiber functional material of the present invention, the specific steps are as follows:

[0033] ① Preparation of dialdehyde fiber: Take 4g of dry eucalyptus pulp fiber in a conical flask, add 200mL of potassium hydrogen phthalate buffer (0.05M, pH=3), then add 2.4g of sodium periodate, After wrapping with tin foil, stir at 35°C for 4 hours, and finally add 10 mL of ethylene glycol to terminate the reaction, filter and wash the product, and dry to obtain dialdehyde fibers.

[0034] ② Preparation of carboxylated cellulose nanofibers: Add 180 mL of sodium phosphate buffer solution (0.05 M, pH=6.8) to 2 g of dialdehyde fibers, and stir the suspension in a sealed flask at 500 rpm and 60 ° C, then Add 0.032g TEMPO, add 1.69M, 1.183mL sodium hypochlorite solution, then add 2.1307g sodium chlorite, oxidize for 16h, add 5mL ethanol to quench, wash and dry to obtain carboxylated cellulose nanofibers.

[0035] ③Preparation o...

Embodiment 2

[0038] The preparation of the multi-responsive intelligent nanofiber functional material of the present invention, the specific steps are as follows:

[0039] ① Preparation of dialdehyde fiber: Take 4g of absolute dry bagasse pulp fiber in a conical flask, add 200mL of potassium hydrogen phthalate buffer (0.05M, pH=3), then add 2.0g of sodium periodate, and use After wrapping in tin foil, stir at 30°C for 3.5 hours, and finally add 10 mL of ethylene glycol to terminate the reaction, filter and wash the product, and dry to obtain dialdehyde fibers.

[0040] ② Preparation of carboxylated cellulose nanofibers: Add 180 mL of sodium phosphate buffer solution (0.05 M, pH=6.8) to 2 g of dialdehyde fibers, and stir the suspension in a sealed flask at 500 rpm and 55 ° C, then Add 0.030g TEMPO, add 1.69M, 1.183mL sodium hypochlorite solution, then add 2.1307g sodium chlorite, oxidize for 15h, add 5mL ethanol to quench, wash and dry to obtain carboxylated cellulose nanofibers.

[0041] ...

Embodiment 3

[0044] The preparation of the multi-responsive intelligent nanofiber functional material of the present invention, the specific steps are as follows:

[0045] ① Preparation of dialdehyde fiber: Take 4g of dry bamboo pulp fiber in a conical flask, add 200mL of potassium hydrogen phthalate buffer (0.05M, pH=3), then add 3.0g of sodium periodate, and use After wrapping in tin foil, stir at 40°C for 4.5 hours, and finally add 10 mL of ethylene glycol to terminate the reaction, filter and wash the product, and dry to obtain dialdehyde fibers.

[0046] ②Preparation of carboxylated cellulose nanofibers: Add 180mL of sodium phosphate buffer solution (0.05M, pH=6.8) to 2g of dialdehyde fibers, and stir the suspension in a sealed flask at 500rmp and 65°C, then Add 0.035g TEMPO, add 1.69M, 1.183mL sodium hypochlorite solution, then add 2.1307g sodium chlorite, oxidize for 17h, add 5mL ethanol to quench, wash and dry to obtain carboxylated cellulose nanofibers.

[0047] ③Preparation of p...

PUM

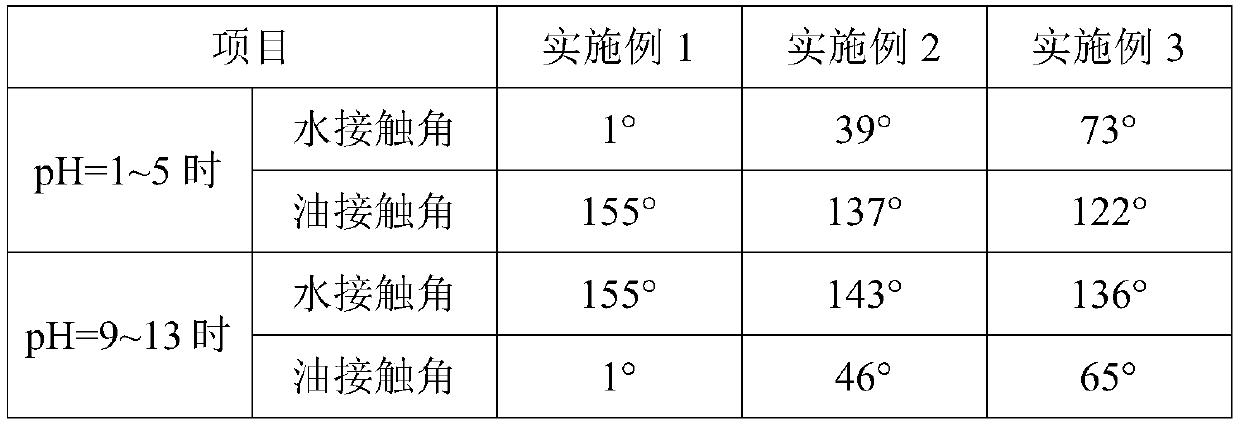

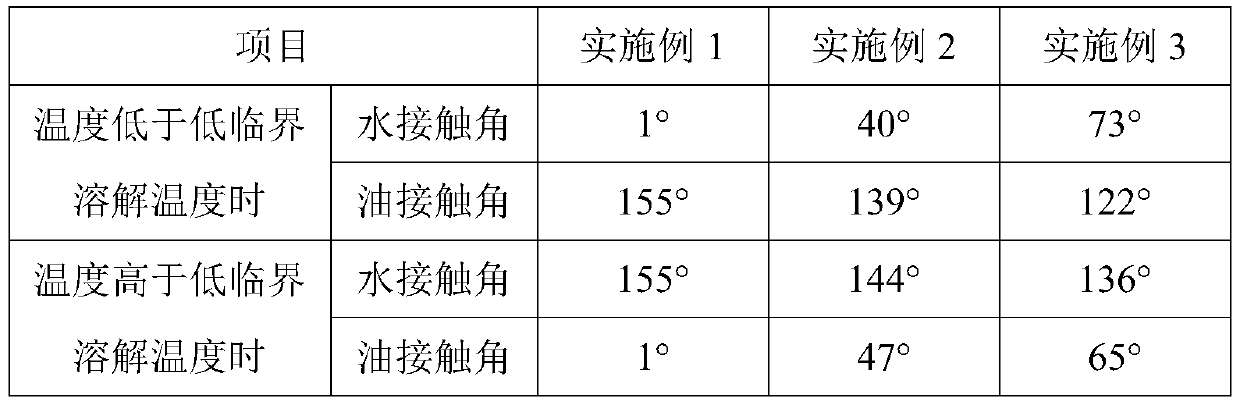

| Property | Measurement | Unit |

|---|---|---|

| Water contact angle | aaaaa | aaaaa |

| Oil contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com