Rapid testing technology for internal deformation field of lithium ion battery structure

A lithium-ion battery, fast technology, used in the use of wave/particle radiation, material analysis using wave/particle radiation, measurement devices, etc. problem, to achieve the effect of reducing radiation damage, shortening exposure time and total imaging time, shortening exposure time and total imaging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

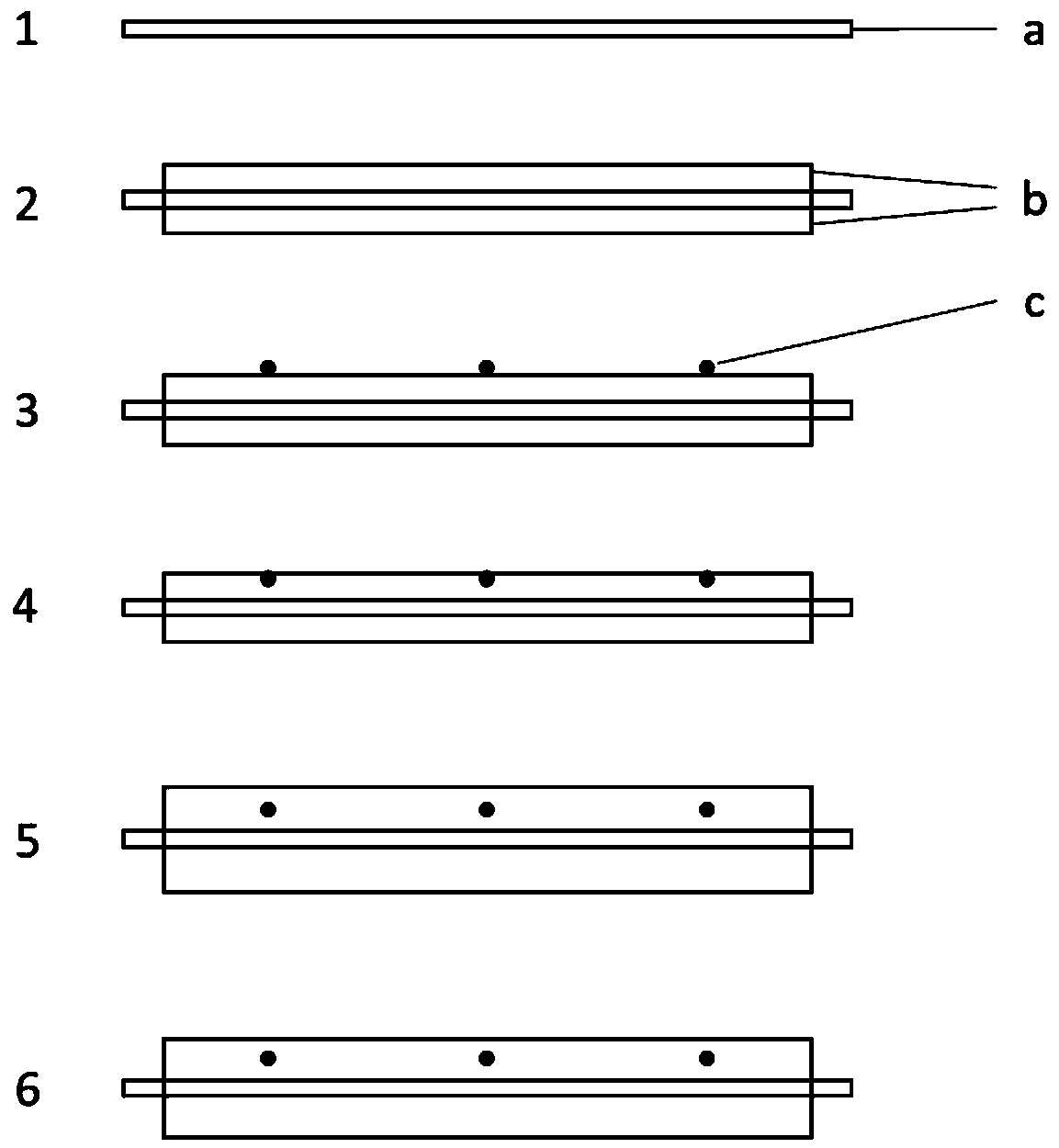

[0024] see figure 1 , the present invention provides a technical solution: a fast CT imaging internal deformation measurement method based on the construction method of lithium-ion battery internal voxel features, including the following technical solutions: (1-2) on both sides of the positive and negative current collector a Coating slurry b prepared by mixing active materials, binders and conductive agents; (3) preparing 15-20 micron-sized internal marking points c containing tungsten elements, and the positive and negative electrodes after one coating Add the internal marking point c on the surface of the electrode sheet; certainly, those skilled in the art know that the material of the internal marking point c is not limited to tungsten, as long as its absorption coefficient to X-rays is greater than that of copper to X-rays; it is preferably much greater than that of copper to X-rays. The material of the X-ray absorption coefficient; (4) after baking the positive and nega...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com