Adsorption-low-temperature thermal catalyst for removing volatile organic compounds

A volatile organic and catalyst technology, applied in the field of VOCs treatment, can solve the problems such as the decline of catalytic performance and the application limitation of powder catalysts, and achieve the effect of easy production and application, flexible adjustment of particle size, and acceptable particle size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

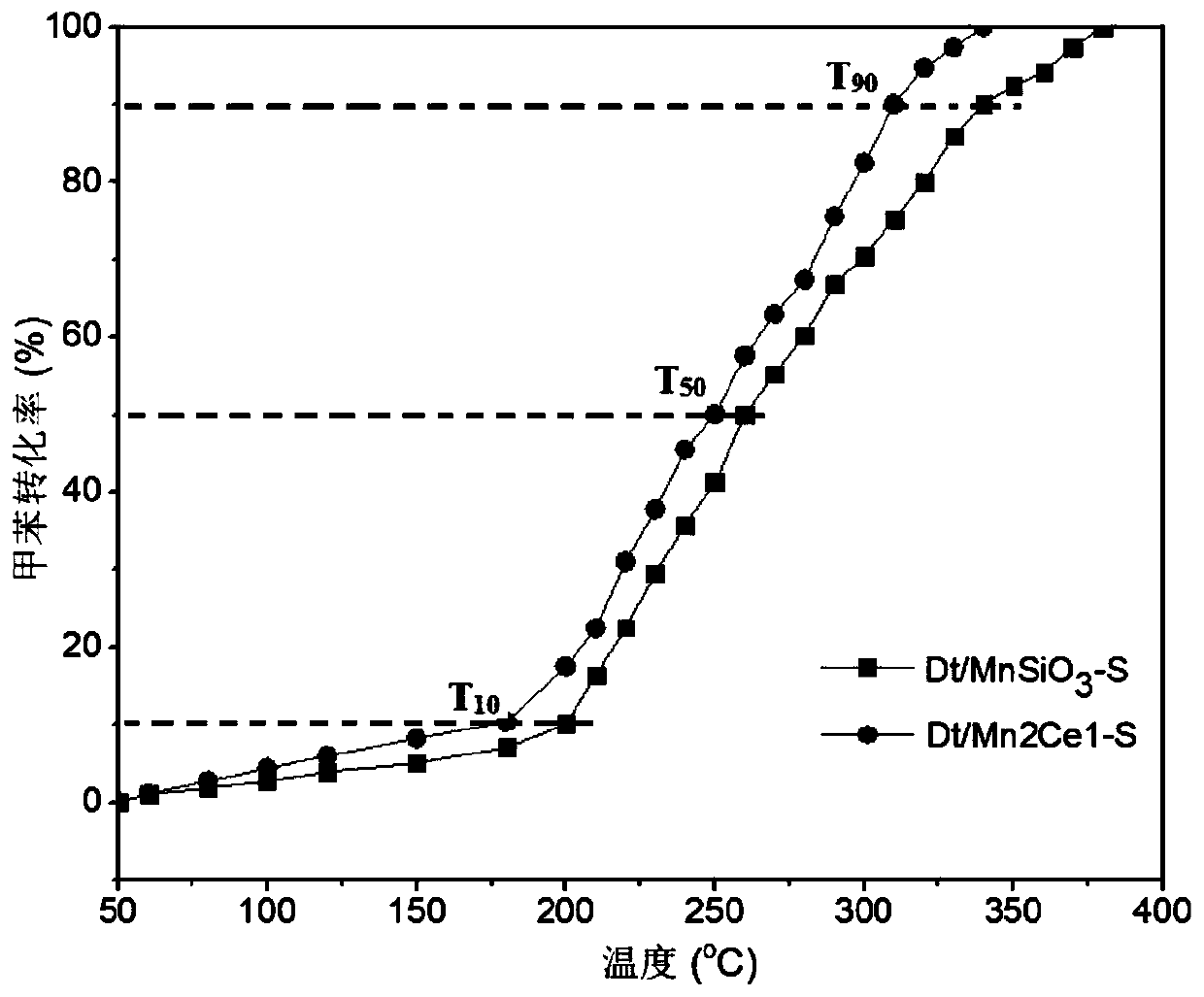

[0023] (1) Catalyst matrix powder (Dt / Mn 2 Ce 1 ) preparation

[0024] Dissolve 52.0g of cerium nitrate hexahydrate and 37.9g of potassium permanganate in 1000mL of water and stir for 20min; adjust the pH to 2 with 37% hydrochloric acid; stir for 20min; add 360g of diatomaceous earth powder and react at room temperature for 2h.

[0025] The mixed solution was transferred to a 1500mL airtight reactor, heated to 100°C, and reacted for 12h. After cooling to room temperature, take it out, rinse with pure water and ethanol 2-3 times after filtration, and dry at 80°C for 6 hours. Then calcined at 350°C for 4h, the material was cooled and ground to obtain the target sample Dt / Mn 2 Ce 1 powder.

[0026] (2) Catalyst particles (Dt / Mn 2 Ce 1 -S) Preparation:

[0027] 84g Dt / Mn 2 Ce 1 , After mixing 3g starch, 5g calcium carbonate, 5g magnesium carbonate, 3g sodium silicate and 25mL pure water, granulate with a pellet machine. Dry at 80°C for 5h, calcinate at 900°C for 1h, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com