Efficient method for treating acidic iron-containing wastewater generated by waste coal mine

An acidic and coal mine technology, applied in mining wastewater treatment, chemical instruments and methods, water pollutants, etc., can solve problems such as watershed pollution, achieve high removal rate, high efficiency, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

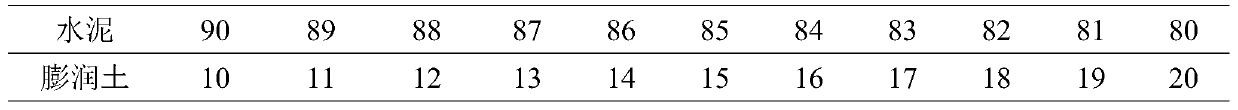

[0045] The acidic iron-containing wastewater from a coal mine gushing out of an abandoned mine in Guizhou Province was used for experiments. The raw water quality is shown in Table 1. The water sample is treated with calcium oxide, which is commonly used in the traditional neutralization method and has a better effect, and the treatment agent of the present invention. The components of the treatment agent of the present invention used in the experiment are 80% of Portland cement and 20% of bentonite.

[0046]Totally 4 barrels of water are used in the experiment, 15L of every barrel, respectively add 1.0% calcium oxide (mass percentage, hereinafter all the same), add 1.0% treatment agent of the present invention, 1.5% treatment agent of the present invention, 2.0% treatment agent of the present invention After the addition, the aeration reaction was 60 minutes, and then stood still for 5 hours, and the supernatant liquid was taken for detection. The detection results and the re...

Embodiment 2

[0055] The coal mine acidic iron-containing wastewater gushed out of an abandoned mine in Guizhou Province was tested. The raw water quality is shown in Table 4. The treatment agent of the present invention used in the experiment is a different ratio of raw materials to treat the water sample. details as follows:

[0056] Proportion 1: Ordinary Portland cement 80%, bentonite 20%;

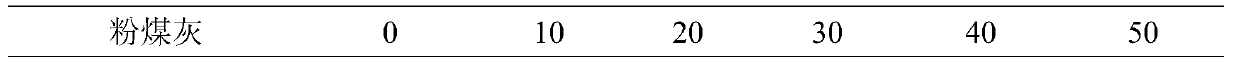

[0057] Proportion 2: Ordinary Portland cement 60%, bentonite 15%, fly ash 25%;

[0058] Proportion three: Ordinary Portland cement 40%, bentonite 10%, fly ash 50%;

[0059] Proportion four: fly ash 100%.

[0060] There are 4 barrels of water in the experiment, each barrel is 15L, adding treatment agent ratio 1 1.0% (mass percentage, the same below), ratio 2 1.0%, ratio 3 1.0%, ratio 4 1.0%, aeration after adding React for 90 minutes, then let it stand for 5 hours, take the supernatant for detection, the detection results and the removal rate of each item are shown in Table 5.

[0061] Table 4 Ra...

Embodiment 3

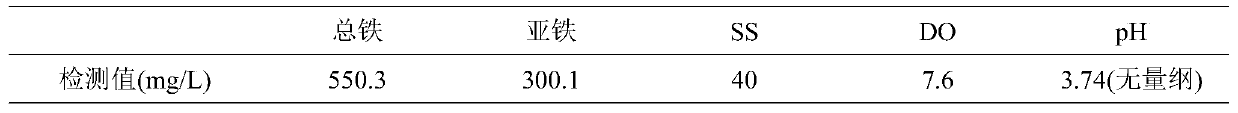

[0067] A field pilot test was carried out for a tailings mine water in Guizhou Province. The water quality of the acidic mine water is shown in Table 6. The components of the treatment agent of the present invention used in the experiment are 90% of ordinary Portland cement and 10% of bentonite.

[0068] Get totally 4 barrels of tailings mine water on the spot, every barrel 20L, add respectively treatment agent 0.5% (mass percentage, hereinafter all the same) in the present invention, treatment agent 1.0% in the present invention, treatment agent 1.5% in the present invention, this invention The treatment agent in the invention is 2.0%. After the addition, it is aerated for 90 minutes, then left to stand for 5 hours, and the supernatant is taken for detection. The detection results and the removal rates of each item are shown in Table 7.

[0069] Table 6 Raw Water Quality Inspection Form

[0070]

[0071] Table 7 Analysis of water quality testing data and pollutant removal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com