Bionic modified plant fiber modified soybean protein adhesive and preparation method thereof

A plant fiber and soybean protein technology, which is applied in the field of wood adhesives, can solve the problems of formaldehyde release and achieve the effects of improving reactivity, improving mechanical properties, and enhancing mechanical interlocking and interface bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

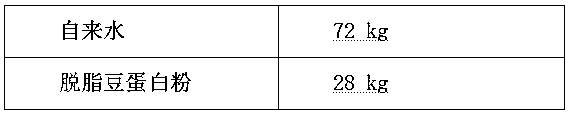

[0040] This example relates to the preparation of a bionic-treated plant fiber modified soybean protein adhesive, and the adhesive is prepared according to the following weight ratio:

[0041]

[0042] Including the following steps:

[0043] (1) In a reaction kettle equipped with a stirrer, thermometer and condensing device (the reaction is carried out at room temperature), add tap water, SSNF and TA and stir evenly

[0044] (2) In step (1), add defatted soy protein powder, PTGE and K in sequence 2 CO 3 Stir evenly to prepare the soybean meal protein adhesive;

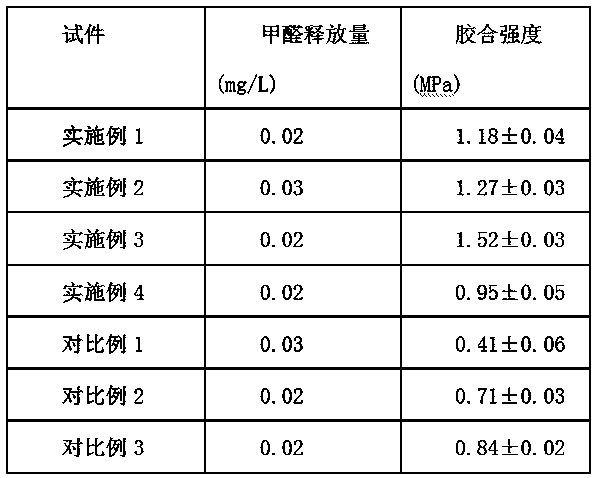

[0045] Four batches of parallel samples were prepared by the same process, and the performance and quality indicators of the processed adhesives are shown in Table 1.

Embodiment 2

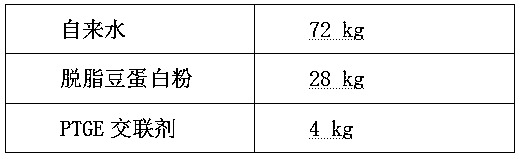

[0047] This example relates to the preparation of a bionic-treated plant fiber modified soybean protein adhesive, and the adhesive is prepared according to the following weight ratio:

[0048]

[0049] Including the following steps:

[0050] (1) In a reaction kettle equipped with a stirrer, thermometer and condensing device (the reaction is carried out at room temperature), add tap water, SSNF and TA and stir evenly

[0051] (2) In step (1), add defatted soy protein powder, PTGE and K in sequence 2 CO 3 Stir evenly to prepare the soybean meal protein adhesive;

[0052] The quality index of gained vegetable protein adhesive is shown in Table 1

Embodiment 3

[0054] This example relates to the preparation of a bionic-treated plant fiber modified soybean protein adhesive, and the adhesive is prepared according to the following weight ratio:

[0055]

[0056] Including the following steps:

[0057] (1) In a reaction kettle equipped with a stirrer, thermometer and condensing device (the reaction is carried out at room temperature), add tap water, SSNF and TA and stir evenly

[0058] (2) In step (1), add defatted soy protein powder, PTGE and K in sequence 2 CO 3 Stir evenly to prepare the soybean meal protein adhesive;

[0059] The quality index of the obtained soybean protein adhesive is shown in Table 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com