Graphene loaded transition metal silicate nano film material for lithium ion battery and preparation method of nano film material

A transition metal salt, transition metal technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of reversible low conductivity volume expansion, long time consumption, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

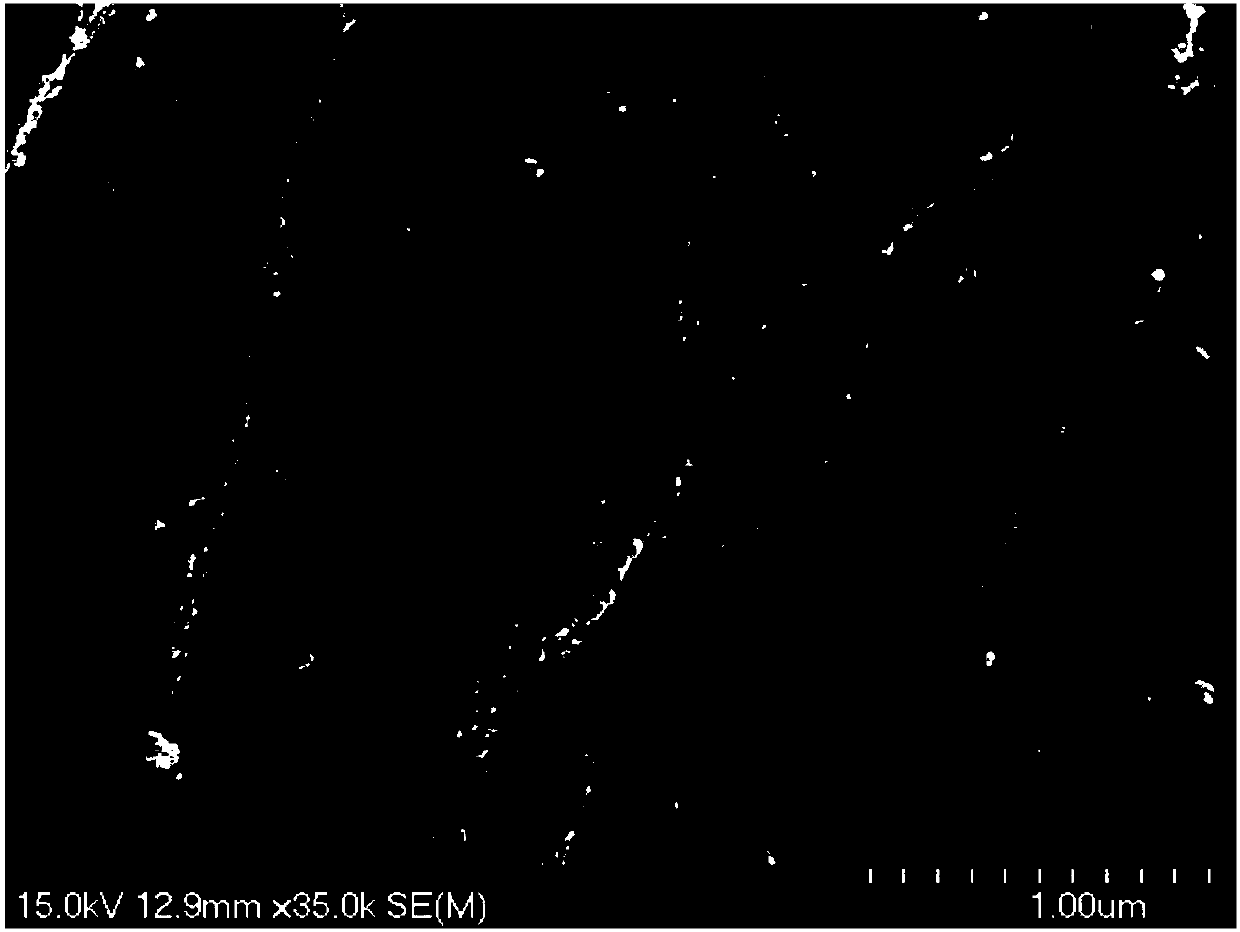

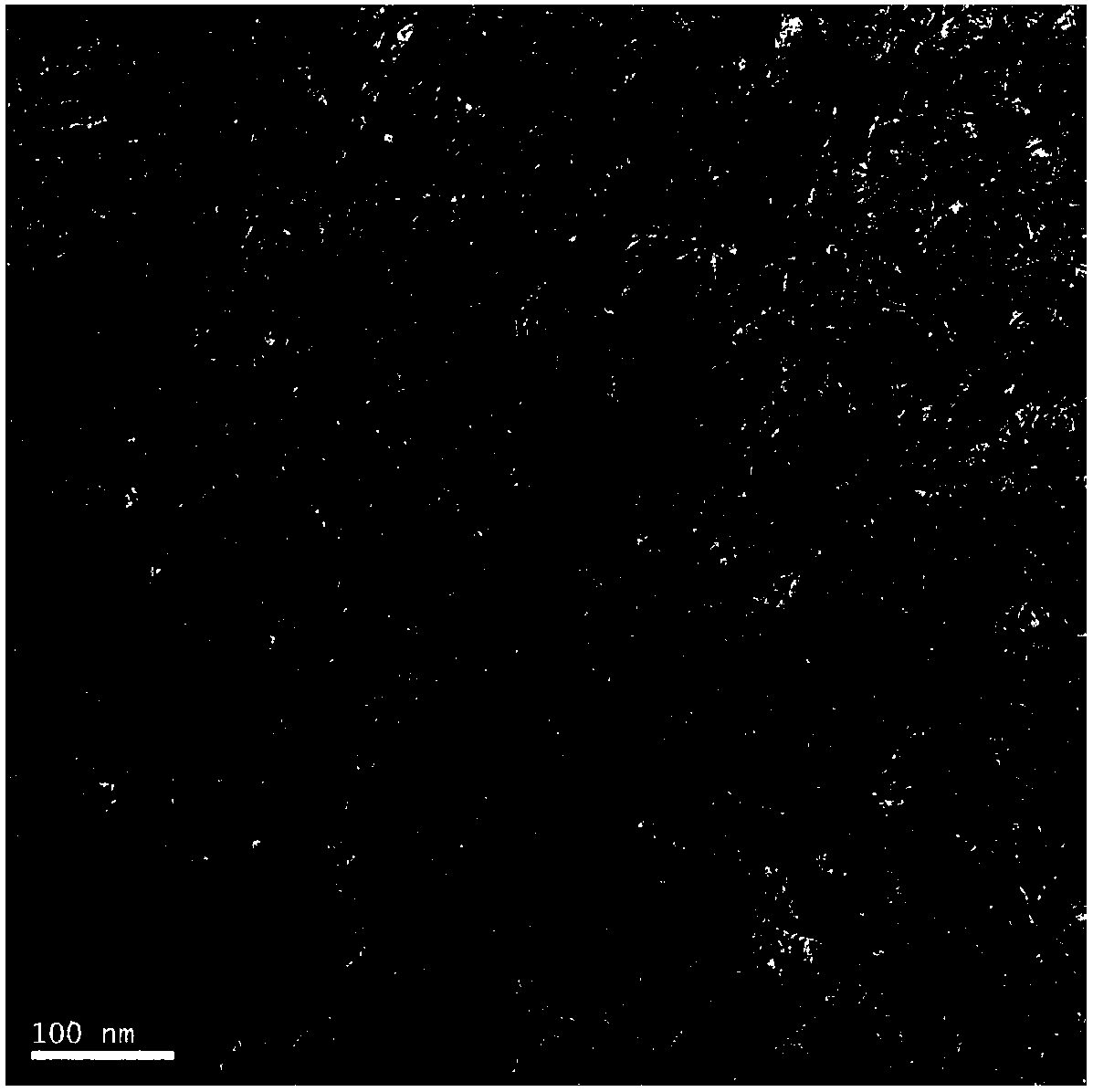

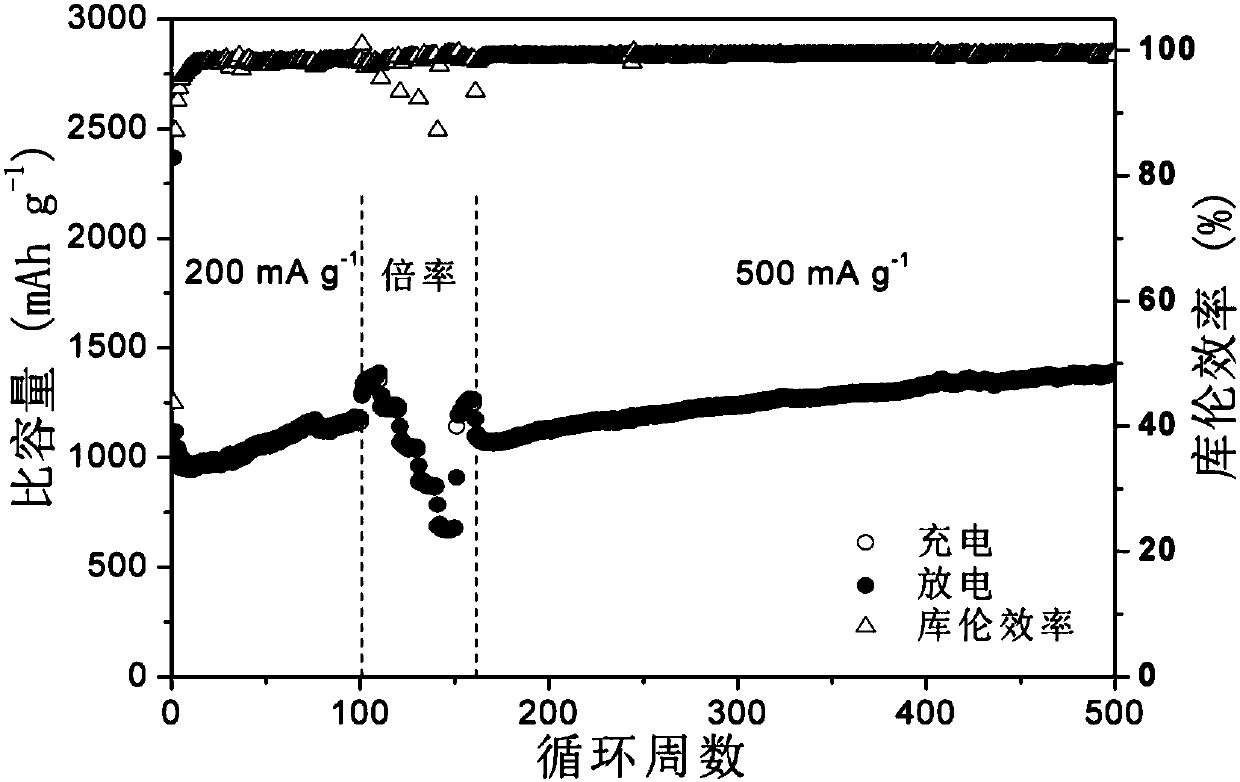

[0036] Take a certain proportion of cobalt acetate tetrahydrate, urea, graphene and silicon tetrachloride in the polytetrafluoroethylene liner (volume 50mL), so that the molar ratio of cobalt acetate tetrahydrate, urea, graphene and silicon tetrachloride The ratio is 2:10:2.5:1, where the molar weight of cobalt acetate tetrahydrate is 2 mmol; add ethylene glycol to about 2 / 3 of the lining volume, stir and sonicate for 1 hour, and then put it into a blast drying oven at 200°C for reaction Take it out after 2 hours, and open it after cooling to room temperature to obtain a suspension of the reaction product; remove the suspension of the reaction product to a centrifuge tube for centrifugation, pour off the supernatant, and repeat the centrifugation with an appropriate amount of absolute ethanol for 2 to 3 times. A reaction product precipitate is obtained; the reaction product precipitate is placed in a vacuum drying oven for drying, and finally the dried product is taken out and ...

Embodiment 2

[0040] Take a certain proportion of cobalt acetate tetrahydrate, urea, graphene and silicon tetrachloride in the polytetrafluoroethylene liner (volume 50mL), so that the molar ratio of cobalt acetate tetrahydrate, urea, graphene and silicon tetrachloride The ratio is 2:1:100:1, wherein the molar weight of cobalt acetate tetrahydrate is 2 mmol; add ethylene glycol to about 2 / 3 of the inner liner volume, stir and sonicate for 1 hour, and then put it into a blast drying oven at 200°C for reaction Take it out after 2 hours, and open it after cooling to room temperature to obtain a suspension of the reaction product; remove the suspension of the reaction product to a centrifuge tube for centrifugation, pour off the supernatant, and repeat the centrifugation with an appropriate amount of absolute ethanol for 2 to 3 times. A reaction product precipitate is obtained; the reaction product precipitate is placed in a vacuum drying oven for drying, and finally the dried product is taken ou...

Embodiment 3

[0042] Take a certain proportion of cobalt acetate tetrahydrate, urea, graphene and silicon tetrachloride in the polytetrafluoroethylene liner (volume 50mL), so that the molar ratio of cobalt acetate tetrahydrate, urea, graphene and silicon tetrachloride The ratio is 2:100:1:1, where the molar weight of cobalt acetate tetrahydrate is 2 mmol; add ethylene glycol to about 2 / 3 of the lining volume, stir and sonicate for 1 hour, and then put it into a blast drying oven at 200°C for reaction Take it out after 2 hours, and open it after cooling to room temperature to obtain a suspension of the reaction product; remove the suspension of the reaction product to a centrifuge tube for centrifugation, pour off the supernatant, and repeat the centrifugation with an appropriate amount of absolute ethanol for 2 to 3 times. A reaction product precipitate is obtained; the reaction product precipitate is placed in a vacuum drying oven for drying, and finally the dried product is taken out and g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com