A kind of nano-iron oxide composite material induced by mxene, preparation method and application thereof

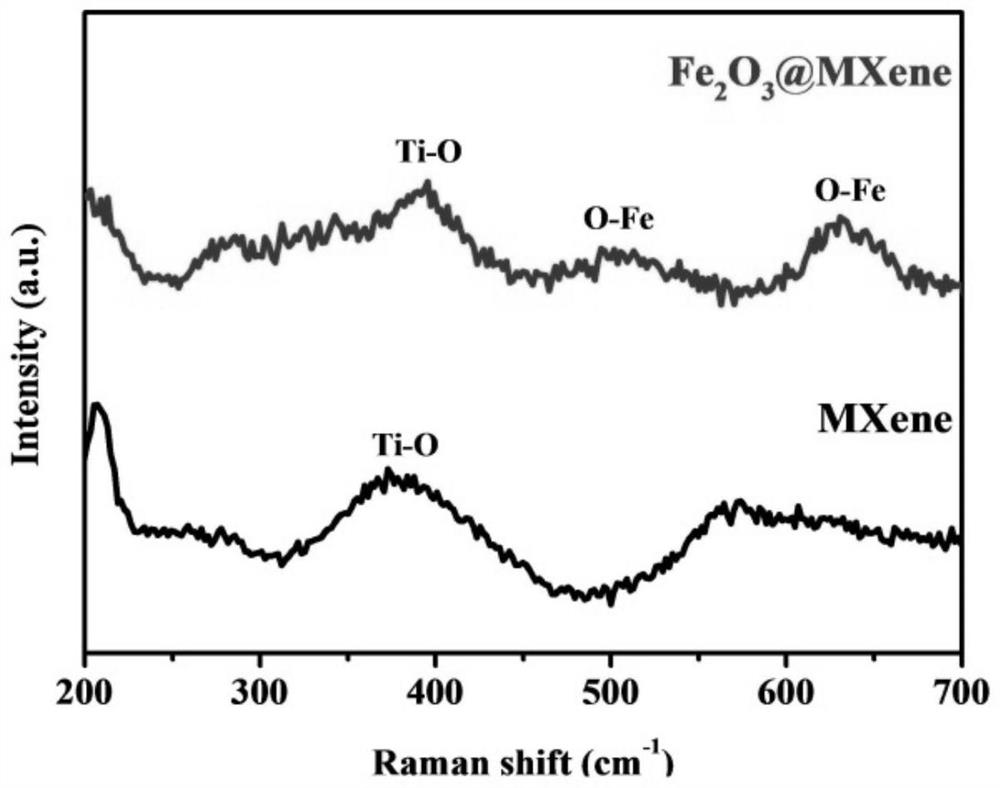

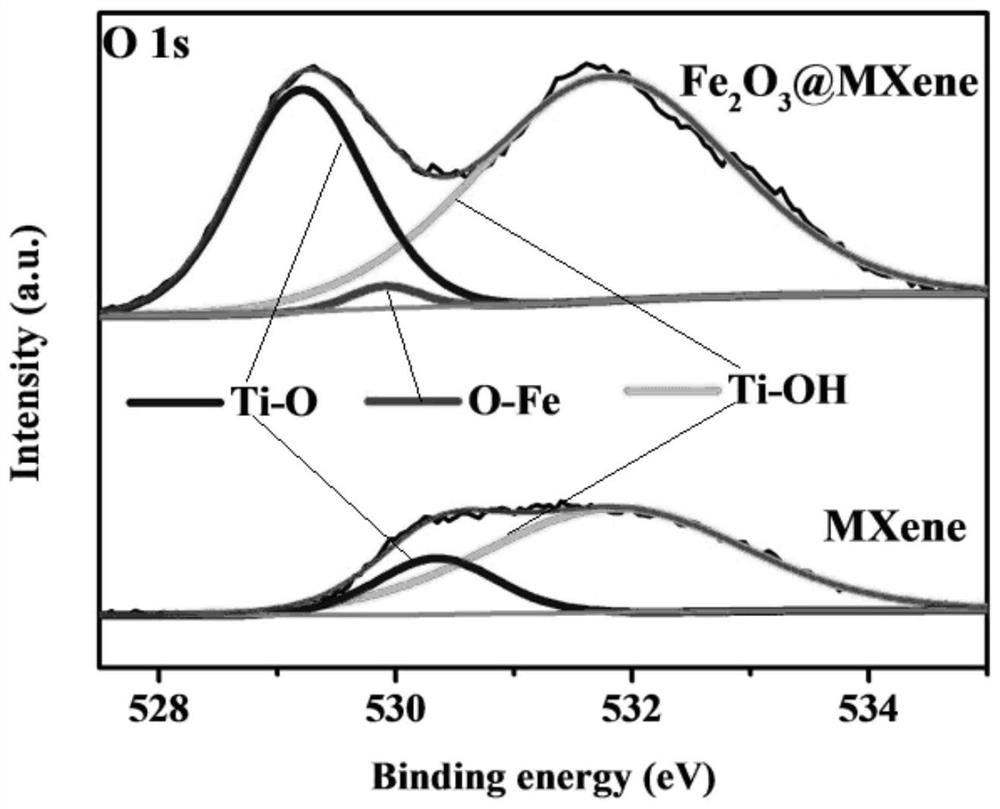

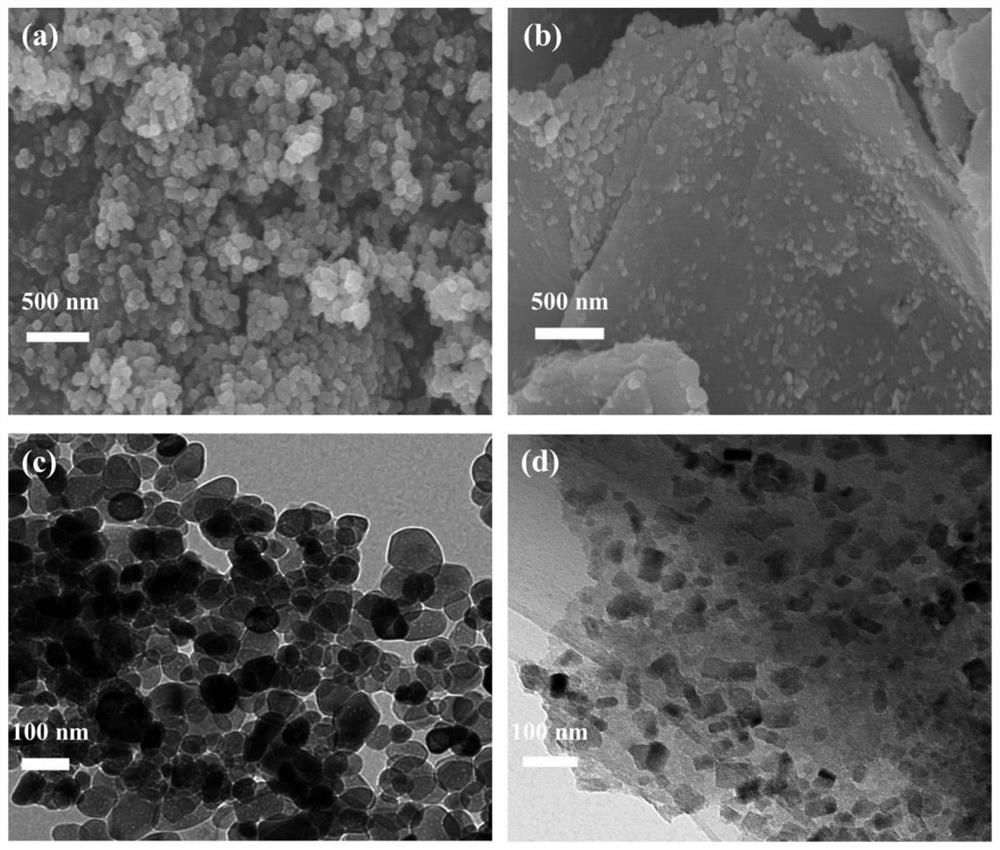

A nano-iron oxide and composite material technology is applied in the field of nano-iron oxide composite material and preparation, and can solve the problems of volume expansion, reducing the effect of buffering the volume expansion of iron oxide, and different particle sizes of iron oxide particles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The invention provides a kind of preparation method of the nano iron oxide composite material that MXene induces growth, comprises the following steps:

[0036] A) will Ti 3 AlC 2 Adding to HF solution for etching to obtain an etching product;

[0037] B) mixing the etching product with tetramethylammonium hydroxide solution for intercalation, and then adding LiOH for reaction to obtain an intermediate product;

[0038] The mass ratio of the LiOH to the etching product is (0.04-0.09):1;

[0039] C) dispersing the intermediate product in water, ultrasonicating for 1 to 1.5 hours and then centrifuging, the obtained supernatant is MXene solution;

[0040] D) sequentially adding iron salt solution and lye to the MXene solution to perform in-situ growth to obtain a nano-iron oxide composite material;

[0041] The iron salt solution includes iron salt and dispersant.

[0042] In the present invention, it is preferred to stir the solution in the solution for sufficient et...

Embodiment 1

[0063] (1) Preparation of MXene solution with small flakes and -OH functional group content of 50%

[0064] Weigh 10g Ti 3 AlC 2 (MAX) powder was slowly added to 100 mL of HF solution with a mass fraction of 40%, and stirred continuously for 24 h at 50°C. Then, the fully etched solid product was washed with deionized water for 3 to 5 times, and then placed in an oven at 60° C. for vacuum drying for 12 hours to obtain a powder product.

[0065] Weigh 1 g of the above powder, add 25 mL of tetramethylammonium hydroxide (TMAOH) solution with a mass fraction of 25%, stir at room temperature for 36 h, then add LiOH solid powder with a mass of 0.07 g, stir at room temperature for 24 h, centrifuge, and dissolve the solid The isolate was re-dispersed in 500 mL deionized water, ultrasonicated for 1 h, and the solution was centrifuged at 3500 rpm for 1 h, and the supernatant obtained was a MXene solution with small flakes and 50% -OH functional group content.

[0066] (2) Preparation ...

Embodiment 2

[0076] (1) Preparation of MXene solution with small flakes and -OH functional group content of 30%

[0077] Weigh 10g Ti 3 AlC 2 (MAX) powder was slowly added to 100 mL of HF solution with a mass fraction of 40%, and stirred continuously for 24 h at 70°C. Then, the fully etched solid product was washed with deionized water for 3 to 5 times, and then placed in an oven at 80° C. for 12 hours in vacuum to obtain a powder product.

[0078] Weigh 2 g of the above powder, add 50 mL of tetramethylammonium hydroxide (TMAOH) solution with a mass fraction of 25%, stir at room temperature for 48 h, then add LiOH solid powder with a mass of 0.08 g, stir at room temperature for 36 h, centrifuge, and dissolve the solid The isolate was redispersed in 500mL deionized water, ultrasonicated for 1.5h, and the solution was centrifuged at 3500rpm for 1h, and the supernatant obtained was a MXene solution with small flakes and a -OH functional group content of 30%.

[0079] (2) Preparation of dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com