Preparation method and application of co-pyrolyzed biochar of pig bones and bamboo wood

A co-pyrolysis and biochar technology, applied in chemical instruments and methods, water pollutants, alkali metal compounds, etc., can solve the problems of mixed wastewater treatment without co-pyrolysis biochar, and achieve enhanced physical adsorption effect, repeatable The effect of high rate and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

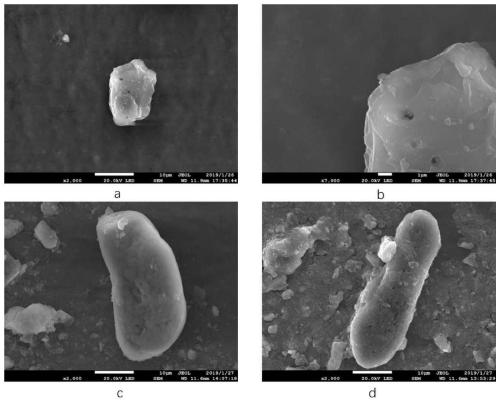

[0035] A method for preparing pig bone and bamboo co-pyrolysis biochar, comprising the following steps:

[0036] 1: Remove impurities, stir and scald the obtained bamboo and pig bones in hot water at 80-100°C to remove impurities;

[0037] 2: drying, the bamboo and pork bones after the impurities are placed in an oven at 105°C for drying;

[0038] 3: Grinding. Grinding the dried bamboo and pig bones with a universal grinder, the grinding time is 1-2min, and the interval is 1-2min. Repeat this 20-30 times to make bone powder and bamboo with a particle size of 130-150μm. Powder, as the raw material of adsorbent;

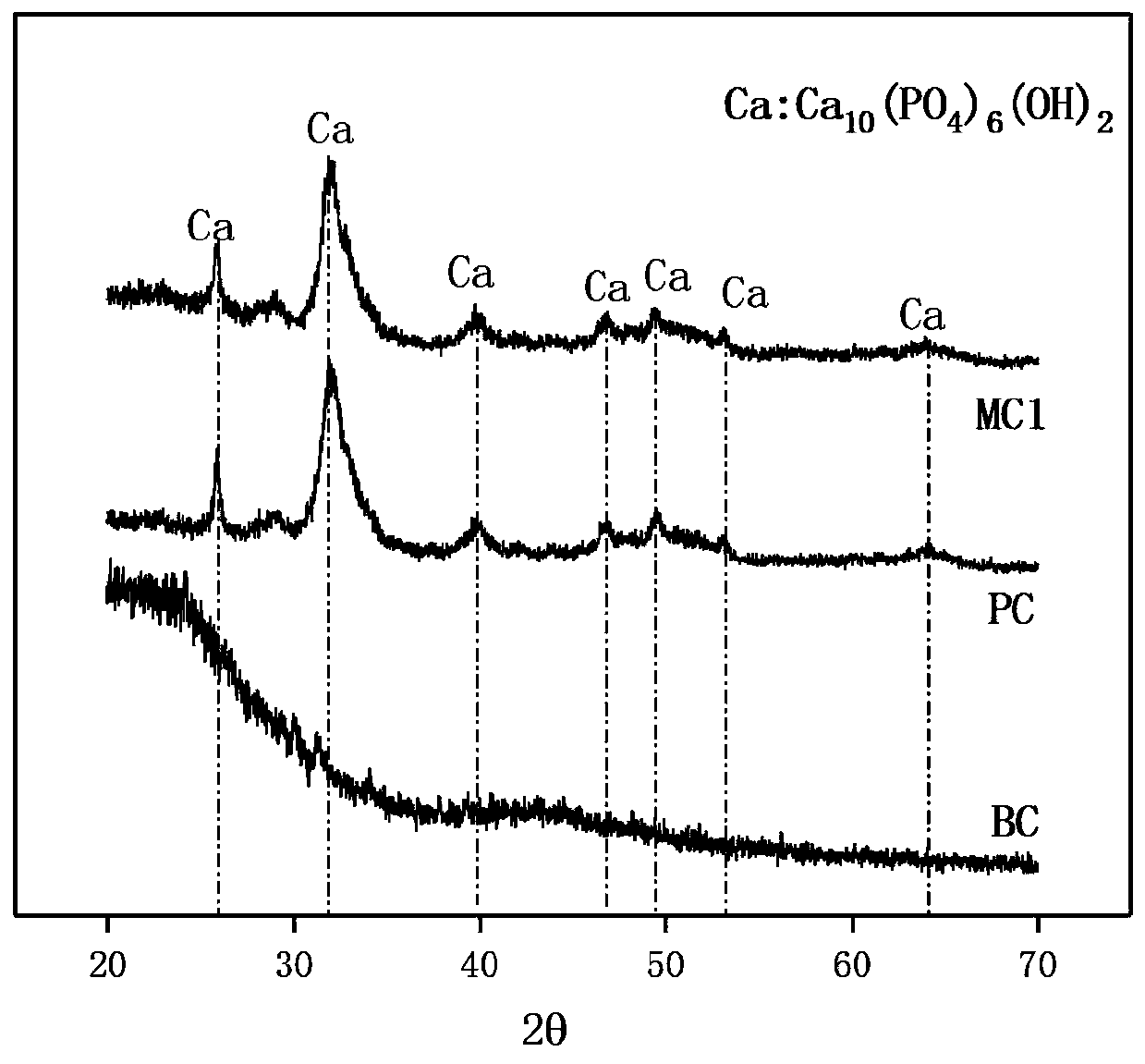

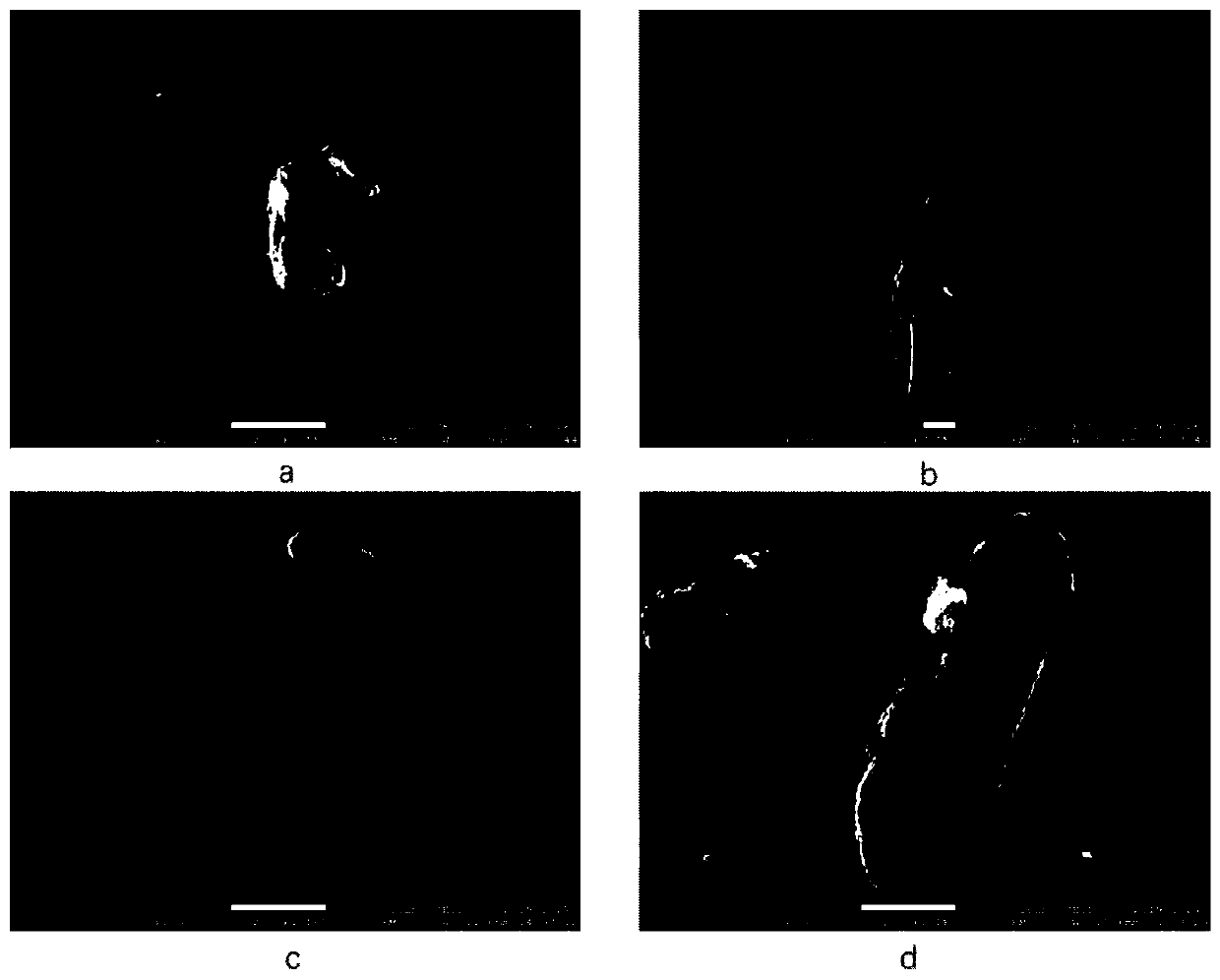

[0039] 4: Pyrolysis, the prepared bamboo powder and pig bone powder are mixed at a mass ratio of 2:3 and then co-pyrolyzed in a vacuum tube furnace at 550°C in a nitrogen atmosphere for 2-2.5h, and the heating rate is 10°C / min, the nitrogen gas flow rate was 50mL / min, and then it was naturally cooled to room temperature and taken out to obtain co-pyrolysis biochar. ...

Embodiment 2

[0041] A method for preparing pig bone and bamboo co-pyrolysis biochar, comprising the following steps:

[0042]1: Remove impurities, stir and scald the obtained bamboo and pig bones in hot water at 80-100°C to remove impurities;

[0043] 2: drying, the bamboo and pork bones after the impurities are placed in an oven at 120°C for drying;

[0044] 3: Grinding. Grinding the dried bamboo and pig bones with a universal grinder, the grinding time is 1-2min, and the interval is 1-2min. Repeat this 20-30 times to make bone powder and bamboo with a particle size of 110-130μm. Powder, as the raw material of adsorbent;

[0045] 4: Pyrolysis, mix the prepared bamboo powder and pig powder with a mass ratio of 3:7, and then carry out co-pyrolysis in a vacuum tube furnace at 700°C in a nitrogen atmosphere for 2-2.5h, and the heating rate is 7°C / min , the nitrogen gas flow rate was 40mL / min, and then it was naturally cooled to room temperature and then taken out to obtain co-pyrolysis bioc...

Embodiment 3

[0047] A method for preparing pig bone and bamboo co-pyrolysis biochar, comprising the following steps:

[0048] 1: Remove impurities, stir and scald the obtained bamboo and pig bones in hot water at 80-100°C to remove impurities;

[0049] 2: drying, the bamboo and pork bones after the impurities are placed in an oven at 80°C for drying;

[0050] 3: Grinding. Grinding the dried bamboo and pig bones with a universal grinder, the grinding time is 1-2min, and the interval is 1-2min. Repeat this 20-30 times to make bone powder and bamboo with a particle size of 75-100μm. Powder, as the raw material of adsorbent;

[0051] 4: Pyrolysis, mix the prepared bamboo powder and pig powder with a mass ratio of 1:3, and then carry out co-pyrolysis in a vacuum tube furnace at 600°C in a nitrogen atmosphere for 2-2.5h, and the heating rate is 8°C / min , the rate of nitrogen gas feeding was 60mL / min, and then it was naturally cooled to room temperature and then taken out to obtain co-pyrolysis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com