Catalyst for highly selective conversion of synthesis gas to acetic acid and its application

A high-selectivity, synthesis gas technology, used in physical/chemical process catalysts, carbon monoxide reaction to prepare carboxylic acid, molecular sieve catalysts, etc., can solve the problem of high price, achieve low price, good reaction performance, and promote the effect of selective transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

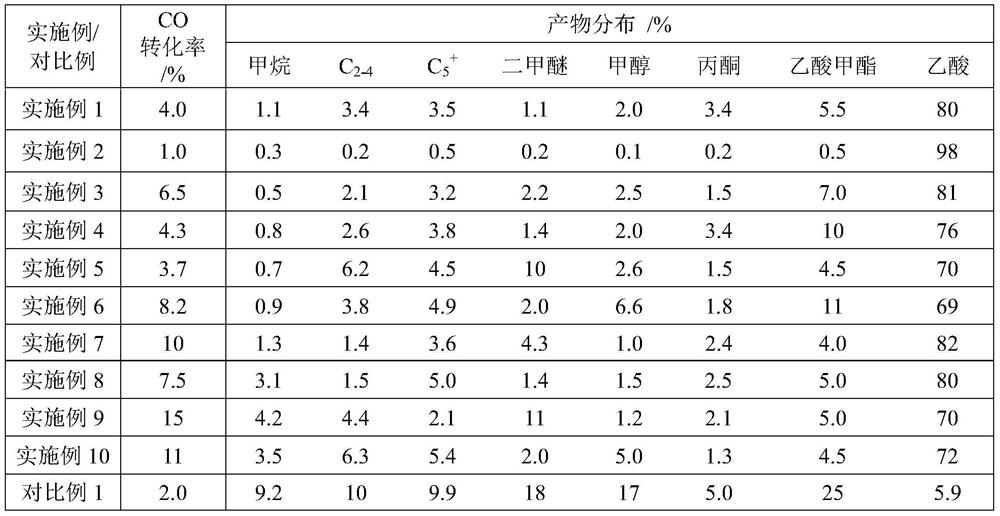

Examples

Embodiment 1

[0025] Weigh 1.0g Zn(NO 3 ) 2 ·6H 2 O was added to 100mL water and stirred at 30°C for 6h; then 25.0g Zr(NO 3 ) 4 ·5H 2 O and 20.0g triethanolamine, stirred for 5h, transferred to a hydrothermal kettle, and hydrothermally treated at 180°C for 12h; the obtained solid was suction filtered, washed until neutral, dried overnight at 120°C, and then the sample was placed in a muffle furnace Raise the temperature at a rate of 5°C / min to 500°C and roast for 6 hours, the product obtained is a zirconium-based solid solution oxide, which is recorded as 3% ZnO-ZrO 2 .

[0026] Take by weighing 2.0g H-MOR molecular sieves and put in fixed-bed reactor and pass through 2% pyridine / N 2 Mixed gas, heated to 300°C at a rate of 5°C / min for 24 hours, and then the sample treated with pyridine was treated with 0.05M NaNO 3 The aqueous solution was treated at 80°C for 2h, and the obtained solid was heated to 500°C in a muffle furnace at a rate of 5°C / min and roasted for 5h, and then the sampl...

Embodiment 2

[0030] Weigh 0.7g AlCl 3 Add 100mL of water, stir at 30°C for 3h; then add 25.0g of Zr(NO 3 ) 4 ·5H 2 O and 20.0g disodium ethylenediaminetetraacetate, stirred for 6h, transferred to a hydrothermal kettle, and hydrothermally treated at 200°C for 12h; the obtained solid was suction filtered, washed until neutral, dried overnight at 120°C, and then the sample was placed In the muffle furnace, the temperature was raised to 550°C at a rate of 5°C / min and roasted for 8 hours, and the product obtained was a zirconium-based solid solution oxide, which was recorded as 3% Al 2 o 3 -ZrO 2 .

[0031] Weigh 2.0g H-ZSM-35 molecular sieve and put it into a fixed-bed reactor and feed it with 2% pyridine / N 2 Mixed gas, heated to 200°C at a rate of 5°C / min for 12 hours, and then the sample treated with pyridine was treated with 0.05M NaNO 3 The aqueous solution was treated at 80°C for 2h, and the obtained solid was heated to 500°C in a muffle furnace at a rate of 5°C / min and roasted for...

Embodiment 3

[0035] Weigh 1.2g Ca(NO 3 ) 2 4H 2 O was added to 100mL of water and stirred at 30°C for 12h; then 25.0g of Zr(NO 3 ) 4 ·5H 2 O and 20.0g citric acid, stirred for 10h, transferred to a hydrothermal kettle, and hydrothermally treated at 220°C for 36h; the obtained solid was suction filtered, washed until neutral, dried overnight at 120°C, and then the sample was placed in a muffle furnace Raise the temperature at a rate of 5°C / min to 600°C for 10 hours, and the product obtained is a zirconium-based solid solution oxide, which is recorded as 3% CaO-ZrO 2 .

[0036] Weigh 2.0g H-ZSM-11 molecular sieve and put it into a fixed-bed reactor and feed it with 2% pyridine / N 2 Mixed gas, heated to 100°C at a rate of 5°C / min for 6 hours, and then the sample treated with pyridine was treated with 0.05M NaNO 3 The aqueous solution was treated at 80°C for 2h, and the obtained solid was heated to 500°C in a muffle furnace at a rate of 5°C / min and roasted for 5h, and then the sample was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com