Preparation method of a self-floating carbon nitride/cellulose acetate flexible photocatalytic porous film

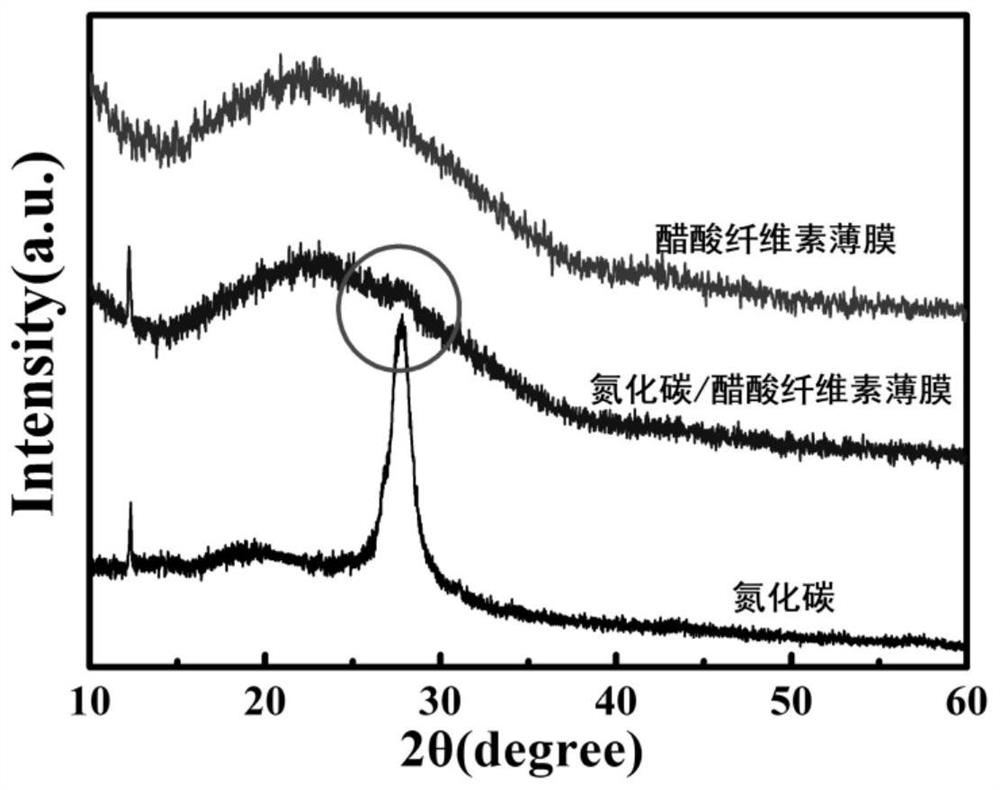

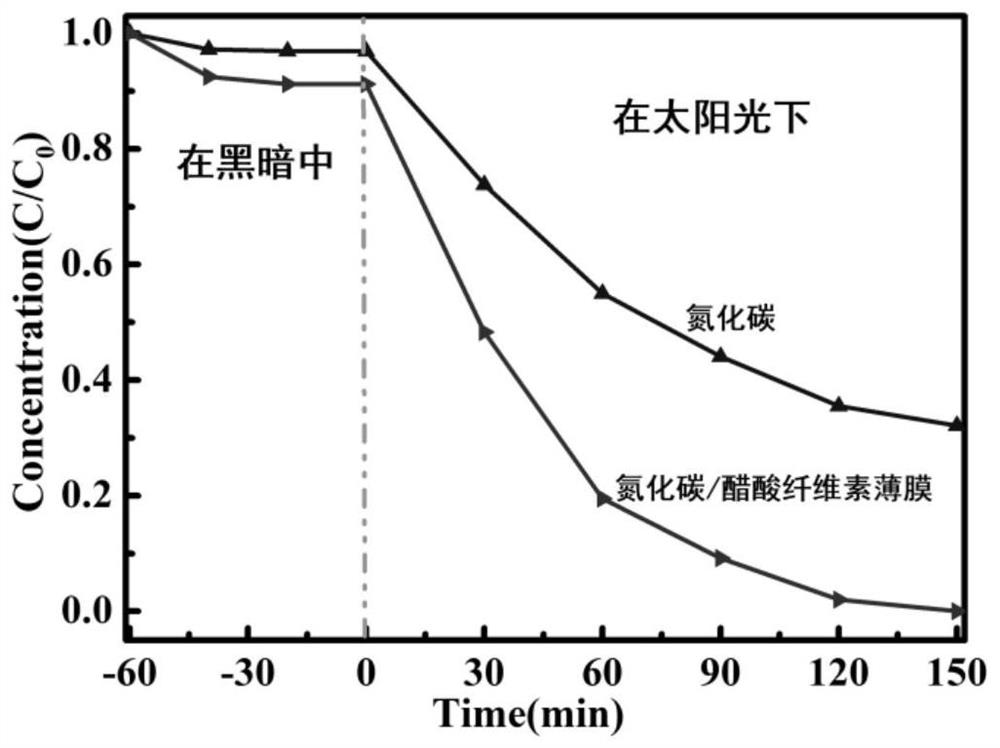

A cellulose acetate, porous film technology, applied in organic compound/hydride/coordination complex catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of solution contact area and light absorption properties, etc. To achieve the effect of promoting photocatalytic performance, improving stability, and enhancing binding capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] In one embodiment of the present invention, the preparation method of the provided photocatalytic thin film material comprises the following steps:

[0040] 1) Preparation of oxidized acidified carbon nitride:

[0041] Add carbon nitride powder prepared by conventional calcination into concentrated sulfuric acid solution and stir for 8-12 hours, then pour into deionized water with a volume ratio of 1:8-1:12, ultrasonicate for 8-12 hours, and centrifuge in deionized water After washing for 4 to 6 times and drying at 60°C, sulfuric acid oxidized acidified carbon nitride can be obtained. Among them, the reagents for oxidizing and acidifying carbon nitride include nitric acid in addition to sulfuric acid.

[0042] 2) Preparation of carbon nitride and cellulose acetate mixed solution:

[0043] Disperse the carbon nitride prepared in step 1) into the acetone solution so that the concentration of the added carbon nitride is 10g / L, 20g / L, 30g / L, 40g / L, 50g / L respectively, and...

Embodiment 1

[0049] (1) Carbon nitride is obtained by calcining melamine at 550 degrees Celsius for 4 hours. After the obtained carbon nitride is ground evenly, it is added to concentrated sulfuric acid at a mass ratio of 1:20, magnetically stirred for 8 hours, and then poured into the In deionized water, the volume of deionized water is 10 times the volume of concentrated sulfuric acid, sonicated for 8 hours, centrifuged and washed 4 times, and dried at 60°C to obtain carbon nitride oxidized and acidified by sulfuric acid.

[0050] (2) Take by weighing 0.5 g of the carbon nitride obtained by the sulfuric acid oxidation acidification obtained in step (1), join in 10 mL of acetone solution, ultrasonic 4h, then weigh 0.5 g of cellulose acetate, join in the above-mentioned carbon nitride dispersion, Sonicate for 30 minutes to obtain a carbon nitride / cellulose acetate dispersion.

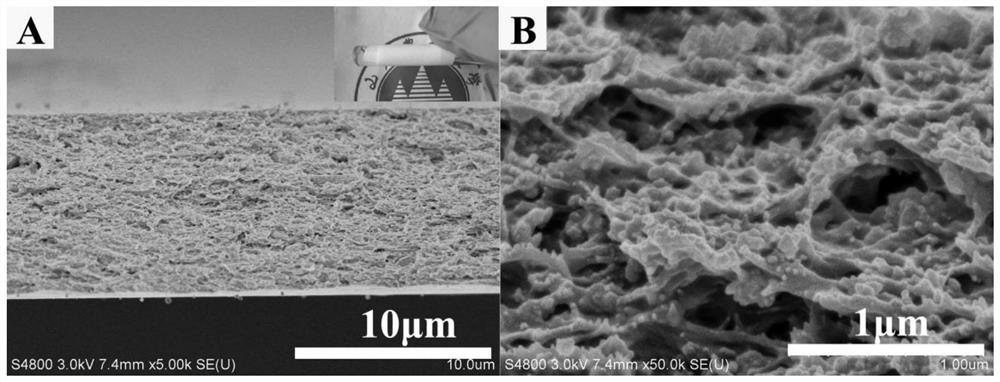

[0051] (3) Pour the carbon nitride / cellulose acetate dispersion prepared in step (2) onto a clean glass plate, sc...

Embodiment 2

[0053] (1) Carbon nitride is obtained by calcining melamine at 550 degrees Celsius for 4 hours. After the obtained carbon nitride is ground evenly, it is added to concentrated nitric acid according to the mass ratio of 1:20, magnetically stirred for 8 hours, and then poured into the In deionized water, the volume of deionized water is 10 times the volume of concentrated nitric acid, ultrasonicated for 8 hours, centrifuged and washed 4 times, and dried at 60°C to obtain carbon nitride oxidized and acidified by nitric acid.

[0054] (2) Take by weighing 0.5 g of the carbon nitride oxidized and acidified by nitric acid obtained in step (1), add it to 10 mL of acetone solution, ultrasonicate for 4 hours, then weigh 0.5 g of cellulose acetate, and add it to the above-mentioned carbon nitride dispersion, Sonicate for 30 minutes to obtain a carbon nitride / cellulose acetate dispersion.

[0055] (3) Pour the carbon nitride / cellulose acetate dispersion prepared in step (2) onto a clean ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com