Carboxylated PEG derivative, hydrogel based on carboxylated PEG derivative as well as preparation methods and applications thereof

A derivative and carboxylation technology, applied in medical science, prosthesis, etc., can solve problems such as inability to repair with bone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] Example 1: Preparation of four-arm polyethylene glycol / polylysine hydrogel

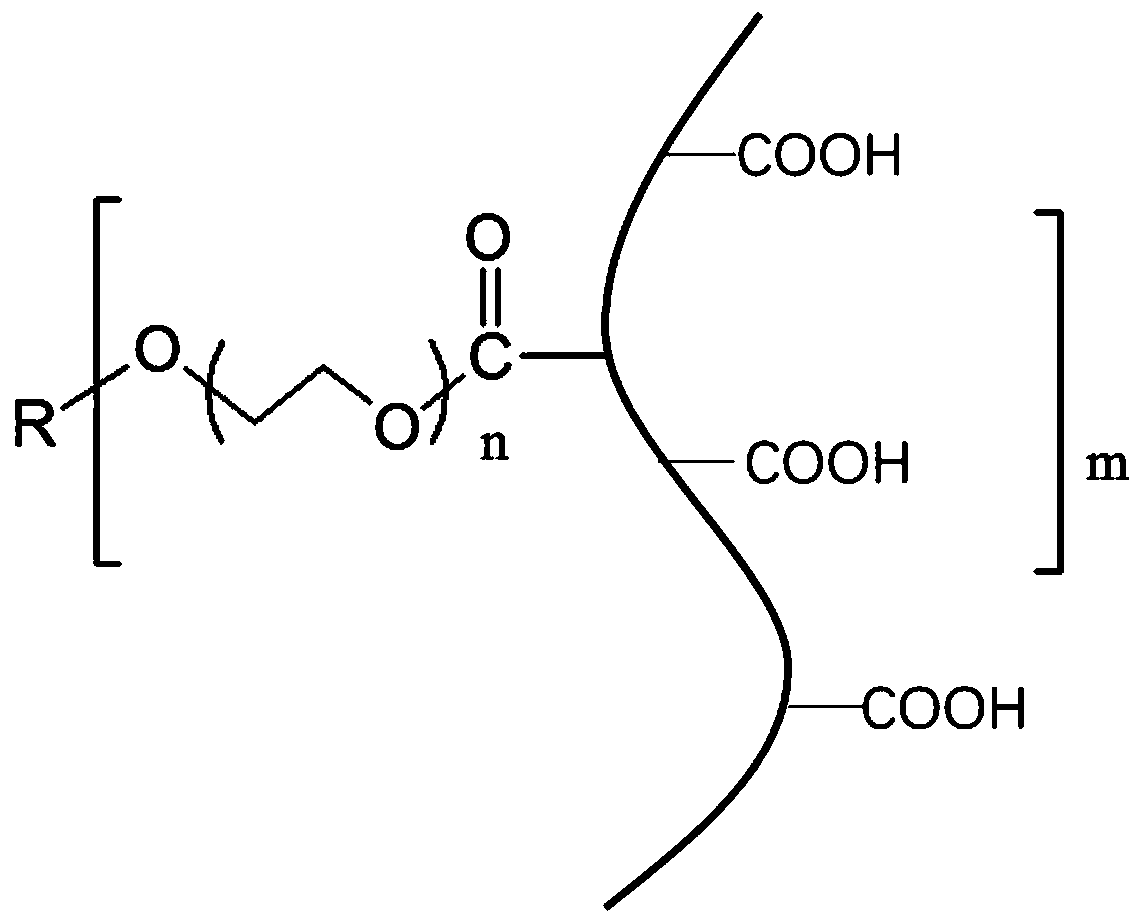

[0087] (1) Preparation of polyethylene glycol-polysuccinimide malate (PEG-1)

[0088] 23.8g α,β-polymalic acid (Mn=1050), 19.35g four-arm polyethylene glycol (Mn=7450), 5.0g EDC and 2.85g 4-dimethylaminopyridine (DMAP) were added to anhydrous DMF, Then the reaction was carried out at room temperature for 24 hr. Then 2.6g of N-hydroxysuccinimide and 4.4g of EDC were added to continue the reaction for 20hrs. Then, it was precipitated in excess ethyl acetate, acetone and n-hexane mixed solvent, and dried to obtain PEG-1. Its structure is attached figure 1 .

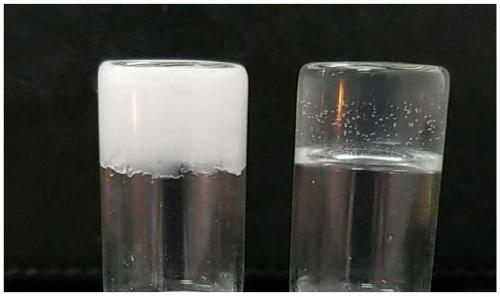

[0089] (2) Preparation of four-arm polyethylene glycol / polylysine hydrogel

[0090] The polylysine (molecular weight is about 4400) is made into 5w / v% concentration with deionized water, 2ml and 0.2g of PEG-1 are dissolved in 2ml deionized water, the two are mixed and stirred evenly, and solidified after about 2 minutes. gel, see attach...

Embodiment 2

[0095] Example 2: Preparation of four-arm polyethylene glycol / polylysine / hydroxyapatite hydrogel

[0096] (1) Preparation of polyethylene glycol-polysuccinimide malate (PEG-1)

[0097] 23.8g α,β-polymalic acid (Mn=1050), 19.35g four-arm polyethylene glycol (Mn=7450), 5.0g EDC and 2.85g 4-dimethylaminopyridine (DMAP) were added to anhydrous DMF, Then the reaction was carried out at room temperature for 24 hr. Then 2.6g of N-hydroxysuccinimide and 4.4g of EDC were added to continue the reaction for 20hrs. Then, it was precipitated in excess ethyl acetate, acetone and n-hexane mixed solvent, and dried to obtain PEG-1.

[0098] (2) Preparation of four-arm polyethylene glycol / polylysine / hydroxyapatite hydrogel

[0099] The polylysine (molecular weight is about 4400) is made into 5w / v% concentration with deionized water, take 2ml, take 0.2g of PEG-1 and dissolve it with 2ml of deionized water and 0.05g of hydroxyapatite, and stir the above substances It is uniform and solidifies...

Embodiment 3

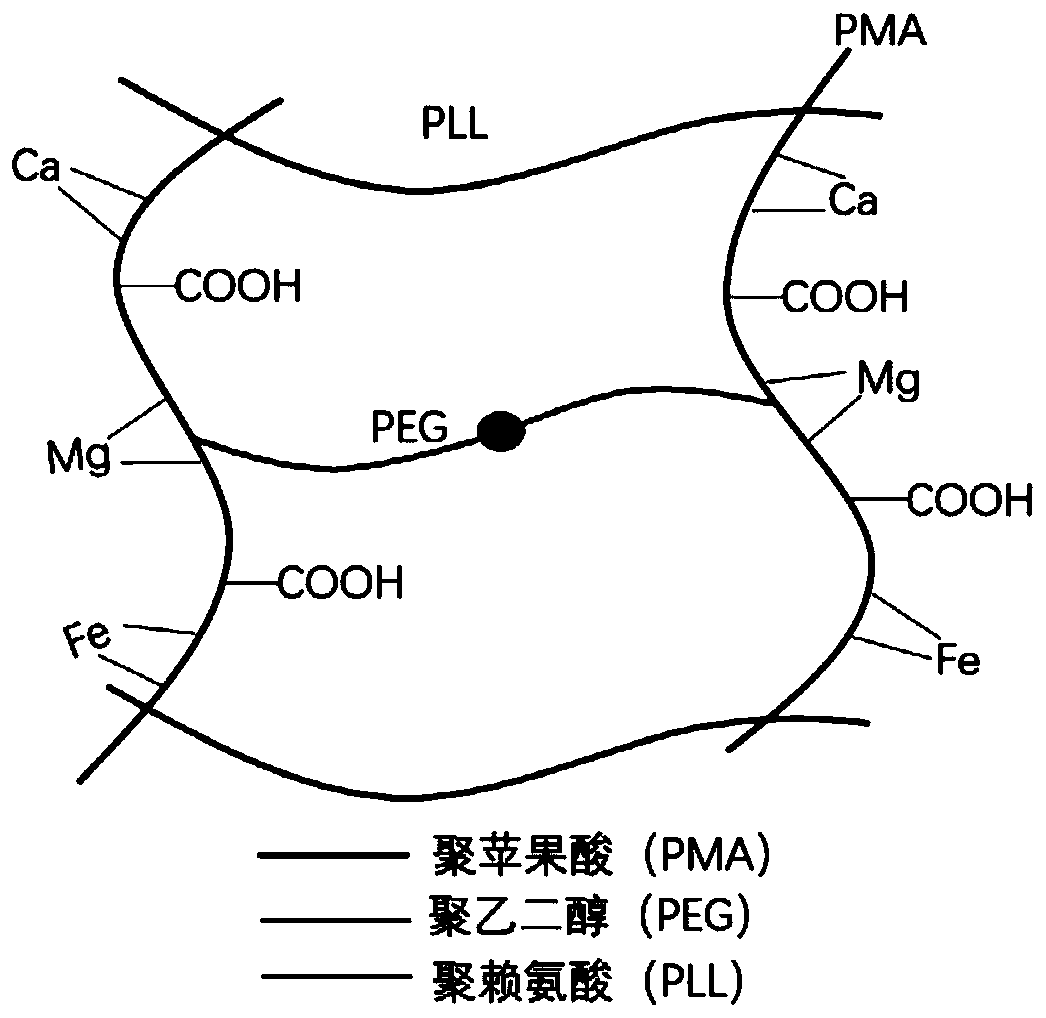

[0105] Example 3: Four-arm polyethylene glycol / polylysine / Ca 2+ / Fe 2+ / Mg 2+ Preparation of hydrogels

[0106] (1) Preparation of polyethylene glycol-polysuccinimide malate (PEG-1)

[0107] 28.8g α,β-polymalic acid (Mn=1600), 19.35g four-arm polyethylene glycol (Mn=7450), 5.0g EDC and 2.85g 4-dimethylaminopyridine (DMAP) were added to anhydrous DMF, Then the reaction was carried out at room temperature for 24 hr. Then 2.6g of N-hydroxysuccinimide and 4.4g of EDC were added to continue the reaction for 20hrs. Then, it was precipitated in excess ethyl acetate, acetone and n-hexane mixed solvent, and dried to obtain PEG-1.

[0108] (2) Preparation of four-arm polyethylene glycol / polylysine / hydroxyapatite hydrogel

[0109] The polylysine (molecular weight is about 4400) is made into 2.5w / v% concentration with deionized water, take 2ml, add 0.2g PEG-1, 0.011g calcium hydroxide, 0.016g hydroxyapatite, stir well, It cured into a gel after about 1 minute and 30 seconds.

[01...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com